A Sustainable Green Approach for Synthesis of Bis(indolyl) Methanes in Ionic Liquid

Rakesh P. Chaudhari1,2 , Ganesh R. Chaudhari1

, Ganesh R. Chaudhari1 and Hemant A. Mahajan2*

and Hemant A. Mahajan2*

1Department of Chemistry, Arts and Science College, Bhalod, Taluka-Yawal, Dist-Jalgaon MS, India.

2Department of Chemistry, MTES’s Smt. G.G. Khadse College, Muktainagar, Taluka- Muktainagar, Dist-Jalgaon MS, India.

Corresponding Author E-mail: hamahajan6@gmail.com

DOI : http://dx.doi.org/10.13005/ojc/400138

Article Received on : 21 Nov 2023

Article Accepted on : 12 Jan 2024

Article Published : 31 Jan 2024

Reviewed by: Dr. Chinu Sharma

Second Review by: Dr. Meenu

Final Approval by: Dr. B .K Sharma

A novel and eco-friendly synthetic protocol has been established to prepare bisindolyl methanes using an easily recyclable ionic liquid and a minimal amount of sulfuric acid. This synthetic approach involves coupling two indole molecules with aromatic aldehydes under mild conditions. The developed synthetic route has remarkable benefits like high percentage yields, shorter time of reaction, and straightforward product isolation. Additionally, the employed ionic liquid was effectively recycled which indicates the sustainability of the synthetic approach.

KEYWORDS:Bis(indolyl) Methanes; Ionic Liquid (ILs); HEMImBr (1-(hydroxymethyl)-3-methyl-1H-imidazol-3-ium bromide)

Download this article as:| Copy the following to cite this article: Chaudhari R. P, Chaudhari G. P, Mahajan H. A. A Sustainable Green Approach for Synthesis of Bis(indolyl) Methanes in Ionic Liquid. Orient J Chem 2024;40(1). |

| Copy the following to cite this URL: Chaudhari R. P, Chaudhari G. P, Mahajan H. A. A Sustainable Green Approach for Synthesis of Bis(indolyl) Methanes in Ionic Liquid. Orient J Chem 2024;40(1). Available from: https://bit.ly/3Snh4A6 |

Introduction

Green chemistry is crucial for the present and the future because it offers a valuable concept for environmentally sound protection. The principles of green chemistry must be considered by chemists, researchers, and the pharmaceutical industry while creating the reaction mechanism and choosing the catalyst. Using green chemistry techniques, we may reduce waste, utilize less harmful chemicals, receive the atom economy, and protect the environment.

However, the limited solubility of synthesized BIMs in aqueous solvents presents a challenge. To minimize this issue, phase transfer catalysts such as ionic liquids are increasingly recognized as potential environmentally friendly catalysts and solvents due to their low vapour pressure, thermal and chemical stability, solvating ability, and ease of recycling. Ionic liquids are formed by combining pyridinium or imidazolium cations with different inorganic or organic anions to create liquid salts, they have a lot of potential uses in different fields such as electrochemistry1, catalysis2, biocatalysis, chemical engineering, and synthesis of heterocyclic compounds3.

Heterocycles are important structural components in both marketed pharmaceuticals and drug discovery targets, with nitrogen-containing rings playing a particularly significant role in drug development due to their diverse pharmacological and therapeutic properties4.

Bis(indolyl)alkanes are a significant class of organic nitrogen compounds obtained from natural sources that have been shown to contribute to biological activity5,6. They serve as a desirable framework in pharmaceutical chemistry and have been demonstrated to exhibit a range of pharmacological actions, including antimicrobial7, Antifungal8, Antioxidant9, anti-HIV10, anti-inflammatory activities11 and Anticancer12 activities.

Recently, several techniques for employing multicomponent processes to create bis(indolyl)alkanes have been found. such as Immobilized ionic liquids on Fe3O4 nanoparticles13, Chitosan supported ionic liquid (CSIL)14, [(CH2)4SO3HMIM][HSO4]15, Silica-Supported Acidic Ionic Liquid16, Dabco-Base Ionic Liquids17, Tetracationic Ammonium Salts18, Transition metal base ionic liquid19, [bmim][MeSO4]20, Morpholinium bisulfate21, Pentafluorophenylammonium triflate22, tetracationic acidic organic salt23 this catalyst has been used to synthesize these compounds.

However, there is scope for improvement in developing a low-cost, cleaner, and environmentally friendly approach with a quicker reaction time.

This paper describes a modest, easy, green, and successful technique for manufacturing BIMs at 80 0C utilising 1(2-hydroxyethyl)-3-methylimidazolium bromide as a solvent and a few drops of Sulfuric acid as a catalyst.

Materials and Methods

All common reagents and solvents were purchased from commercial suppliers and were not purified further. Ionic Liquids were synthesized using some modifications previously reported in the literature24,25. The reaction progress was monitored by carrying out thin layer chromatography (TLC) using silica gel plates, and Melting points were measured using the Digital Analab Scientific Instrument. The FT-IR spectra were recorded using an Alpha II Bruker spectrophotometer. 1H NMR and 13C NMR spectra were recorded on a Bruker Advance Neo 500 MHz spectrometer in CDCl3 or DMSO-d6. Mass spectra were performed on a Waters Q-ToF Micro LC-MS spectrometer.

Experimental

Preparation of ILs.

Pyridine (1 mol) /1 Methyl imidazole (1 mol) and 1-bromopropane (1.1 mol)/2 Bromoethanol (1.1 mol) were placed in a 50 ml two-necked round-bottomed flask. The flask was then placed in an oil bath and heated to 90 °C. The mixture was then stirred continuously for 45 to 60 minutes. The formation of the ionic liquid was confirmed by 1H NMR, 13C CMR, and MS spectroscopy. The excess starting compounds were removed by extracting the mixture with 5 ml of ethyl acetate. The final compound was then dried in a vacuum oven at 80 °C for 4 hours.

Synthesis Methods for Bis(Indolyl)Methanes-

A mixture of Indole (2 mmol), aromatic aldehyde (1 mmol) and HEMImBr 2 ml in a 50 mL round bottom flask in the presence of 2 drops of sulfuric acid, is heated at 80 °C in an oil bath for 23-28 minutes. When the reaction is completed (monitored by TLC), the reaction mixture is allowed to cool at room temperature. Then add approximately 10 gm of crushed ice to the above mixture. The solid product obtained is filtered, washed thoroughly with ice-cold water and dried. Subsequently, the product purification by recrystallization using hot ethanol. Then, the obtained filtrate after the isolation of the product was subjected to evaporation under reduced pressure to recover the ionic liquid. The ionic liquid was then dried in a vacuum oven for 2 hours and subsequently used for the next experimental cycle.

Spectral data

propyl pyridinium bromide (PPBr)

1H NMR (500 MHz, DMSO): δ (ppm) 0.23-0.26(3H, t.), 1.33-1.38(2H, m), 4.22-4.25(2H, t), 8.88-8.90(2H, d.), 7.93-7.97(2H, t.), 8.88-8.90 (1H, t.). 13C NMR (125 MHz, DMSO): 10.11,28.90, 62.42,128.15,144.72, 145.24. Mass (m/z): 202.16.

N-(2-hydroxyethyl) pyridinium bromide (HEPBr):

1H NMR (500 MHz, DMSO): δ (ppm) 3.93-3.97 (2H, q), 4.85-4.87 (2H, t), 5.32(1H, s), 8.26-8.29 (2H, q), 8.72-8.75(1H, t), 9.22-9.23 (2H, d) 13C NMR (125 MHz, DMSO): 35.69, 51.92, 59.20, 122.53, 123.20, 136.66. Mass (m/z): 207.13.

1 methyl 3 propyl imidazolium bromide (PMImBr):

1H NMR (500 MHz, DMSO): δ (ppm) 0.11-0.14(3H, t), 1.11-1.15(2H, m), 3.30(3H, s), 3.49-3.52(2H, t), 6.95-6.96(1H,d), 6.99-7.00 (1H, d), 9.23 (1H, s). 13C NMR (125 MHz, DMSO): 39.71, 111.13, 119.12, 119.39, 119.83, 119.94, 122.11, 123.62, 126.89, 130.52, 131.33, 136.71, 143.11. Mass (m/z): 205.07.

1-(hydroxymethyl)-3-methyl-1H-imidazol-3-ium bromide (HEMImBr):

1H NMR (500 MHz, DMSO): δ (ppm) 3.70-3.71(2H, t), 3.87 (3H, s), 4.23-4.25(2H, t), 5.08 (1H, s), 7.75-7.78(2H, d), 9.22(1H, s) 13C NMR (125 MHz, DMSO): 35.69, 51.92, 59.20, 122.53, 123.20, 136.66. Mass (m/z): 192.14.

3,3′-(4 chloro Phenylmethylene) bis(1H-indole) (3c)

IR υmax Cm-1: 3300, 3177, 2976, 1662, 1572, 1444, 1282. 1H NMR (500 MHz, CDCl3): δ 5.86(1H, s), 6.64(2H, s), 6.99-7.02(2H, t), 7.15-7.18(2H, t), 7.34-7.36(4H, d), 7.22-7.27 (4H, m), 7.92(2H,s, NH). 13C NMR (125 MHz, CDCl3): 39.64, 111.10, 119.25, 119.37, 119.83, 122.10, 123.58, 126.90, 128.37, 130.08, 131.81, 136.71, 142,56. Mass (m/z): 357.09.

3,3′-(4 hydroxy Phenylmethylene) bis(1H-indole) (3d)

IR υmax Cm-1: 3501, 3350, 3110, 2981, 1640, 1455,1226. 1H NMR (500 MHz, CDCl3): δ 4.58(1H, s), 5.82(1H, s), 6.65-6.66(2H, q), 6.73-6.75(2H, m), 6.98-7.01(2H, t), 7.14-7.17(2H, t), 7.19-7.21(2H,d), 7.34-7.39(4H,s), 7.90(2H, s, NH). 13C NMR (125 MHz, CDCl3): 39.36, 111.00, 115.04, 119.22, 119.98, 120.05, 121,93, 123.49, 127.06, 129.83, 136.42, 136.73, 153.80. Mass (m/z): 305.24.

3,3′-(4 nitro Phenylmethylene) bis(1H-indole) (3e)

IR υmax Cm-1: 3250, 2920, 2847, 1578, 1438, 1382, 1237. 1H NMR (500 MHz, CDCl3): δ 5.99(1H,s), 6.68(2H,s), 7.01-7.04(2H,d), 7.18-7.25(2H,t), 7.32-7.34(2H,d), 7.37-7.39(2H,d), 7.49-7.51(2H,d), 8.00(2H,d,NH), 8.13-8.14(2H,d). 13C NMR (125 MHz, CDCl3): 40.22, 111.26, 118.17, 119.57, 119.64, 122.38, 123.63, 126.67, 129.54, 136.71, 151.83. Mass (m/z): 367.26.

3,3′-(4 methoxy Phenylmethylene) bis(1H-indole) (3f)

IR υmax Cm-1: 3422, 2931,1645,1461,1287,1220. 1H NMR (500 MHz, CDCl3): δ 3.76(3H, s), 5.82(1H, s), 6.51(2H, s), 6.79-6.81 (2H,d), 6.97-7.00(2H, t), 7.13-7.16(2H, t), 7.22-7.24 (2H, t), 7.31-7.32 ( 2H, d), 7.36-7.38 (2H, d), 7.85 (2H, s, NH). 13C NMR (125 MHz, CDCl3): 39.36, 55.23, 11.04, 113.59, 119.20, 120.00, 120.06, 121.90, 123.54, 127.09, 129.62, 136.26, 136.73, 157.93. Mass (m/z): 352.04

3,3′-(2 nitro Phenylmethylene) bis(1H-indole) (3g)

IR(ATR)υmax Cm-1: 3311,3104,2981,1662,1562,1572,1455,1265,1170. 1H NMR (500 MHz, DMSO-d6): δ 6.65(2H, s), 6.70(1H, s), 7.03-7.06(2H, t), 7.14-7.28(2H, m), 7.35-7.38 (3H, m) 7.41-7.45 (4H, m),7.86-7.91 (1H, d), 7.91 (2H, s, NH). 13C NMR (125 MHz, DMSO-d6): δ 34.82, 102.63, 111.05, 111.18, 117.71, 119.57, 119.75, 119.82, 120.74, 122.00, 122.25, 123.85, 124.14, 124.38, 126.79, 127.22, 131.10, 132.34, 136.70, 138.01, 149.85 Mass (m/z): 367.35.

Result and Discussion

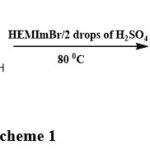

The outcomes of our study demonstrate the production of Synthesised bis(indolyl)alkanes by the interaction between indoles and aldehydes, facilitated by adding 2 drops of sulfuric acid in the ionic liquid HEMImBr. (Scheme-1)

|

Scheme Click here to View Scheme |

In our first attempt, we combined two indole molecules with benzaldehyde at 80°C, using 10 mol% tartaric acid as a catalyst, and conducted the reaction without using a solvent. The reaction was complete after 150 minutes, yielding product 3a at a yield of 57%. To improve the conversion, we switched to a solvent-free, 80 0C, 20 mol% tartaric acid treatment of indole (1a) with benzaldehyde (2a). This time, the reaction needed 135 minutes to complete, and the obtained yield was 62%. (Table 1).

Table 1: The optimization of the indole-benzaldehyde coupling.

|

Sr. No. |

Solvent |

Catalyst |

Temp 0C |

Time |

Yield % |

|

1 |

– |

Tartaric Acid (10%) |

80 |

150 |

57 |

|

2 |

– |

Tartaric Acid (20%) |

80 |

135 |

62 |

|

3 |

Ethanol |

Tartaric Acid (10%) |

80 |

240 |

72 |

|

4 |

Ethanol |

Tartaric Acid (20%) |

80 |

240 |

85 |

|

5 |

PPBr |

– |

80 |

60 |

70 |

|

6 |

PMImBr |

– |

80 |

50 |

75 |

|

7 |

PPBr |

Tartaric Acid (10%) |

80 |

78 |

74 |

|

8 |

PPBr |

Tartaric Acid (20%) |

80 |

72 |

79 |

|

9 |

PMImBr |

Tartaric Acid (10%) |

80 |

70 |

78 |

|

10 |

PMImBr |

Tartaric Acid (20%) |

80 |

60 |

82 |

|

11 |

PPBr |

H2SO4 (2 Drops) |

80 |

43 |

84 |

|

12 |

PMImBr |

H2SO4 (2 Drops) |

80 |

37 |

86 |

|

13 |

HEPBr |

– |

80 |

40 |

82 |

|

14 |

HEMImBr |

– |

80 |

38 |

84 |

|

15 |

HEPBr |

H2SO4 (2 Drops) |

80 |

35 |

89 |

|

16 |

HEMImBr |

H2SO4 (2 Drops) |

80 |

28 |

95 |

We then attempted the same reaction using 10% and 20% mole proportion of tartaric acid under ethanol as a solvent at 80 0C. Then, both reactions were completed in 240 min, with 72% and 85% yields, respectively. Additionally, we conducted the reaction without a catalyst, using propyl pyridinium bromide and 3-propyl 1 methyl imidazolium bromide, and observed a slightly higher yield (70% and 75%). When tartaric acid was added to both ionic liquids at 10% and 20%, we saw an increase in yield.

We turned to strong acids such as sulfuric acid to improve the yield. We observed that in both ionic liquids (PPBr and PMImBr), a significant elevation in the yield of the product was observed. With the addition of sulfuric acid as a catalyst, we obtained yields of 84% and 86% using PPBr and PMImBr, respectively, and we also found that the reaction time decreased from 50 min without a catalyst to 38 min with the sulfuric acid catalyst in PMImBr ionic liquid.

In addition to the previously reported results, we explored using two alternative ionic liquids, HEPBr and HEMImBr, to synthesize bisindolyl methanes. Interestingly, even without the addition of a catalyst, both ionic liquids promoted the reaction with 82% and 84% yields. However, adding two drops of sulfuric acid to either ionic liquid (HEPBr or HEMImBr) led to a significant enhancement in product yield, reaching 89% and 95%, respectively. Furthermore, the reaction times were reduced to 35 minutes for HEPBr and 28 minutes for HEMImBr, demonstrating the synergistic effect of the ionic liquid and sulfuric acid.

In considering these encouraging findings, we moved on to investigate the connection between indole and other aromatic aldehydes. The required BIMs may be efficiently produced by combining indole with various substituted aldehydes. (entry 3a-3j in Table 2).

Table 2: Analytical data of BIMs (3a–3j) catalyzed by 2 drops of H2SO4 in HEMImBr.

|

Sr. No. |

Carbonyl Compound |

Product |

Time (Min) |

Yield (%) |

MP 0C |

|

1 |

C6H5-CHO(2a) |

3a |

28 |

95 |

124-125 |

|

2 |

p-BrC6H4– CHO(2b) |

3b |

27 |

93 |

110–112 |

|

3 |

p-ClC6H4– CHO(2c) |

3c |

25 |

94 |

84-85 |

|

4 |

p-OHC6H4– CHO(2d) |

3d |

27 |

90 |

122-124 |

|

5 |

p-NO2C6H4– CHO(2e) |

3e |

23 |

95 |

220-222 |

|

6 |

p-OCH3C6H4– CHO(2f) |

3f |

25 |

94 |

177-179 |

|

7 |

o-NO2C6H4– CHO(2g) |

3g |

27 |

89 |

139-140 |

|

8 |

o-ClC6H4– CHO(2h) |

3h |

28 |

84 |

73-74 |

|

9 |

p-FC6H4– CHO(2i) |

3i |

27 |

88 |

102-104 |

|

10 |

Isatin(2j) |

3j |

23 |

92 |

308-310 |

The reusability of the ionic liquids (ILs) and catalyst was evaluated. The product, being insoluble in water, was easily separated. The residual solution comprising ionic liquids (ILs) was separated by applying decreased pressure at a temperature of 80 0C. After that, it was subjected to drying for two hours in a vacuum oven at 70 0C. The resulting product was then used again for the same synthesis process. The ILs and the catalyst exhibited reusability with only slightly decreased activity. Table 3 displays the findings.

Table 3: Recyclability of Ionic liquid and catalyst

|

No. of Cycles |

Fresh |

Run 1 |

Run 2 |

Run 3 |

|

Yieldsa |

95 |

93 |

90 |

88 |

|

Time (Min) |

38 |

38 |

39 |

40 |

“Reaction conditions: Indole (2 mmol) and Benzaldehyde (1 mmol); ILs and catalyst; temp: 80 °C; aisolated yields.

Conclusion

HEMImBr proved to be an effective and easy-to-use green solvent in synthesizing Bis indolyl methane. We used two drops of sulfuric acid as a catalyst to get high yields from Indole and many different types of aldehydes, which reduced the use of organic volatile solvents. With this one-pot synthesis, the reaction time was fast, the solvent was cheap, nontoxic, and easily synthesized, and the yields were high since the products were easily separated. As a result, this research gives future researchers interested in investigating these frameworks a feasible, quick, and affordable method.

Acknowledgement

The authors express gratitude to the Principals of Arts and Science College, Bhalod and MTES’s Smt. G. G. Khadse College, Muktainagar, for providing the necessary research facilities.

Conflict of Interest

The author declared that there is no conflict of interest related to this article.

References

- Shekouhy, M.; Hasaninejad, A., Ultrasonics Sonochemistry 2012, 19 (2), 307–313. https://doi.org/10.1016/j.ultsonch.20-11.07.011.

CrossRef - Aupoix, A.; Pégot, B.; Vo-Thanh, G., Tetrahedron 2010, 66 (6), 1352–1356. https://doi.org/10.1016/j.tet.2009.11.110.

CrossRef - Su, Y.-Z.; Fu, Y.-C.; Yan, J.-W.; Chen, Z.-B.; Mao, B.-W., Angewandte Chemie International Edition 2009, 48 (28), 5148–5151. https://doi.org/10.1002/anie.200900300.

CrossRef - Gomtsyan, A., Chemistry of Heterocyclic Compounds 2012, 48 (1), 7–10. https://doi.org/10.1007/s10593-012-0960-z.

CrossRef - Chakrabarty, M.; Ghosh, N.; Basak, R.; Harigaya, Y., Tetrahedron Letters 2002, 43 (22), 4075–4078. https://doi.org/10.1016/s0040-4039(02)00682-2.

CrossRef - Bell, R.; Carmeli, S.; Sar, N., Journal of Natural Products 1994, 57 (11), 1587–1590.

CrossRef - Kamal, A.; Khan, M. N. A.; Srinivasa Reddy, K.; Srikanth, Y. V. V.; Kaleem Ahmed, S.; Pranay Kumar, K.; Murthy, U. S. N., Journal of Enzyme Inhibition and Medicinal Chemistry 2009, 24 (2), 559–565.

CrossRef - Jiang, Y.; Su, L.; Liao, Y.; Shen, Y.; Gao, H.; Zhang, Y.; Wang, R.; Mao, Z., Bioorganic & Medicinal Chemistry Letters 2022, 58, 128525.

CrossRef - Simha, P. R.; Mangali, M. S.; Kuppireddy Gari, D.; Venkatapuram, P.; Adivireddy, P., Journal of Heterocyclic Chemistry 2017, 54 (5), 2717–2724.

CrossRef - Srivastava, A.; Agarwal, A.; Gupta, S. K.; Jain, N., RSC Advances 2016, 6 (27), 23008–23011.

CrossRef - Sarva, S.; Harinath, J. S.; Sthanikam, S. P.; Ethiraj, S.; Vaithiyalingam, M.; Cirandur, S. R., Chinese Chemical Letters 2016, 27 (1), 16–20.

CrossRef - Jamsheena, V.; Shilpa, G.; Saranya, J.; Harry, N. A.; Lankalapalli, R. S.; Priya, S., Chemico-Biological Interactions 2016, 247, 11–21.

CrossRef - Sharma, J.; Kumar, P.; Sillanpaa, M.; Kumar, D.; Nemiwal, M., Inorganic Chemistry Communications 2022, 145, 110055. https://doi.org/10.1016/j.inoche.2022.110055.

CrossRef - Patel, G. M.; Kure, A. S.; Mandawad, G. G.; Hote, B. S.; Konda, S. G., Results in Chemistry 2022, 4, 100436. https://doi.org/10.1016/j.rechem.2022.100436.

CrossRef - Karimi, N.; Oskooi, H.; Heravi, M.; Saeedi, M.; Zakeri, M.; Tavakoli, N., Chinese Journal of Chemistry 2011, 29 (2), 321–323.https://doi.org/10.1002/cjoc.201190085.

CrossRef - Hagiwara, H.; Sekifuji, M.; Hoshi, T.; Qiao, K.; Yokoyama, C., Synlett 2007, (08), 1320–1322. https://doi.org/10.1055/s-2007-977453.

CrossRef - Tong, J.; Li, Y.-W.; Xu, D.-Z., ChemistrySelect 2017, 2 (13), 3799–3803. https://doi.org/10.1002/slct.201700603.

CrossRef - Halimehjani, A. Z.; Barati, V., ChemistrySelect 2018, 3 (11), 3024–3028. https://doi.org/10.1002/slct.201800060.

CrossRef - Gogoi, P.; Dutta, A. K.; Sarma, P.; Borah, R., Applied Catalysis A: General 2015, 492, 133–139. https://doi.org/10.1016/j.apcata.2014.12.013.

CrossRef - Chakraborti, A. K.; Roy, S. R.; Kumar, D.; Chopra, P., Green Chemistry 2008, 10 (10), 1111. https://doi.org/10.1039/b807572g.

CrossRef - Balaskar, R. S.; Shingate, B. B.; Shingare, M. S.; Mane, D. V., Arabian Journal of Chemistry 2016, 9, S120–S123. https://doi.org/10.1016/j.arabjc.2011.02.009.

CrossRef - Khaksar, S.; Ostad, S. M, Journal of Fluorine Chemistry 2011, 132 (11), 937–939. https://doi.org/10.1016/j.jfluchem.2011.07.011.

CrossRef - Halimehjani, A. Z.; Hooshmand, S. E.; Shamiri, E. V., RSC Advances 2015, 5 (28), 21772–21777. https://doi.org/10.1039/c5ra01422k.

CrossRef - Welton, T., Biophysical Reviews 2018, 10 (3), 691–706. https://doi.org/1-0.1007/s12551-018-0419-2.

CrossRef - Tong, B.; Liu, Q.-S.; Tan, Z.-C., The Journal of Physical Chemistry A, 2010, 114 (11), 3782–3787. https://doi.org/10.1021/jp9047538.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.