Rheological Behavior of Corn Oil at Different Viscosity and Shear Rate

University of Bucharest, Faculty of Chemistry, Department of Physical Chemistry, 4-12 Elisabeta Blvd, 030018, Bucharest, Romania.

Corresponding Author E-mail: istanciu75@yahoo.com

DOI : http://dx.doi.org/10.13005/ojc/390212

Article Received on : 27 Feb 2023

Article Accepted on :

Article Published : 09 Mar 2023

In this article I presented the rheological behavior of corn oil studied in the temperature range 40-100°C and shear rates between 3.3 and 1312.0 s-1. The experiments showed the decrease of dynamic viscosity with temperature and shear rate. To study the dependence of dynamic viscosity on temperature, we applied two equations that perfectly describe the rheological behavior of corn oil. These equations are the Andrade equation and the Azian equation for which the correlation coefficients have values close to unity.

KEYWORDS:Corn; Oil; Rheology; Shear Rate; Viscosity

Download this article as:| Copy the following to cite this article: Stanciu I. Rheological Behavior of Corn Oil at Different Viscosity and Shear Rate. Orient J Chem 2023;39(2). |

| Copy the following to cite this URL: Stanciu I. Rheological Behavior of Corn Oil at Different Viscosity and Shear Rate. Orient J Chem 2023;39(2). Available from: https://bit.ly/3l3vmJM |

Introduction

Corn oil is transparent, with a neutral taste. The color and smell depend on the production method. Basic raw materials are mature embryos of corn kernels. Possible colors of corn oil are light yellow, bright yellow, dark red-brown.

Maize is a monotonous annual growth of up to 3 meters. A solid stem with nodes along the entire length is covered with dense linear leaves of a saturated green color. The fruit is a berry. Fruits are collected in gross domestic products (GDPs), covered with leaf-shaped overhangs 1-5.

The oil includes:

Linoleic acid is necessary for the normal activities of the heart, normalizes insulin, stabilizes the activity of the nervous system, improves metabolism.

Oleic acid – Reduces cholesterol, supports the heart muscle.

Palmitic acid – It is necessary to ensure the process of energy accumulation. The most important element in the synthesis of stearic acid. A large amount of palmitic acid is harmful.

Stearic acid must ensure the process of energy accumulation.

Acid archive – It is necessary to normalize the tone of the muscle frame and quick recovery after loads.

Vitamin A (retinol) – reflected on the quality of vision, strengthens resistance to infections, restores skin turgor, and improves the functioning of the gastrointestinal tract.

Vitamin B1 (thiamine) – Improves brain activity, stimulates blood formation, opposes the development of depressive states.

Vitamin P (Rutin) – Contributes to the absorption of vitamin C, normalizes pressure and lipid processes in water, opposes body aging and oncological diseases.

Vitamin K (Philokinon) – Contributes to the healing opposes osteoporosis, stabilizes redox reactions, helps to remove poisons from the body.

Vitamin D necessary for the quality of the nervous system, ensures the strength of the musculoskeletal system and teeth.

Vitamin E (tocopherol) – mandatory for all systems, strong antioxidant, improves skin turgor.

Vitamin C. (Ascorbic acid) – necessary for normal homeostasis, stimulates the endocrine system, strengthens vessel walls, powerful antioxidant.

Magnesium It opposes the formation of stones in a bubble and bustard kidneys, strengthens the heart muscle and the nervous system 6-12.

Phosphorus – The need for normal metabolism, strong teeth and bones, stable kidney work, hearts.

Potassium Necessary for the strength of the heart muscle, normal water-lipid metabolism, good mood.

Copper – It is necessary for persistent immunity, normal bleeding.

The oil is removed from the grain embryos. Natural fruit oil from 32 to 37%.

Pressing (cold or hot), extraction, pressing and extraction.

When pressed, the grain mint is subjected to cold or hot pressure.

In the first case, the raw materials are not treated at high temperatures. As a result, the oil acquires the light color, natural taste and aroma of oilseeds.

In the second case dry fried for some time. This leads to a decrease in the viscosity of the oil, which provides a faster process of extracting the fatty substance from the raw materials.

To neutralize the negative effect of temperature on the oil and not reduce the percentage of production, steam the grain mint. Having a temperature of the raw material at 900C and increasing the humidity up to 12%, the mass is pressed under moderate pressure. At the same time, the mint process provides gives the majority contained in it.

The remaining part is removed under high pressure, applied after drying the raw materials and bring it to a temperature of 1200 °C. The extracted secondary oil, has a pronounced smell, needs refining.

Corn wheat starch is used in the production of tablets, baby powder and glucose. Water in which corn kernels have been soaked, is demand in the production of antibiotics.

In extraction, grain mint is mixed with solvent fatty substance, for example, purified gasoline. The method allows obtaining oil, free of harmful components (resins, oxides, pigments). After extracting the gasoline oil, the latter is completely separated.

When processing mint from very suitable seeds, apply the combined processing of raw materials: pressing and extraction.

Corn oil has a lot of useful properties, so it is:

– Protects against the effects of free radicals due to the impact on the person of chemical substances, adverse emissions

– Improves the activity of the gastrointestinal tract, the nervous, cardiovascular and endocrine systems

– Copies inflammatory processes

– They can be applied to the treatment of burns

– Helps fight skin disorders

– Improves the activity of the pancreas and gall bladder

Material and methods

Corn oil was studied in the temperature range 40-100°C.

Rheological measurements were using a rotational viscometer Rheotest RV which can develop shear rates between 3.3 and 1312 s-1 , with two measuring ranges – I and II, and two speeds – a and b. Depending on the measurement range and rate, apparent viscosity, between 1 and 10 mPa·s can be measured using cylinder S1.

The rheoviscosimeter measures a proportional value, by constant of cylinder with shear stress applied to the measurement system. To obtain the shear stress in mPa, the constant of cylinder is 114 for range I and 567 for range II. . The shear speeds are between 3.3 and 120 s-1.

Results and discussion

The rheogram (shear stress – shear rate dependence) for corn oil, represented in Figure 1 was drawn with data from Table 1. The rheogram shows that viscosities – calculated at each point as the ratio of shear stress and shear rate – decrease with increasing shear rate, which means that this cream has a pseudoplastic behavior.

|

Figure 1: The rheogram of corn oil at increasing the shearing rate and temperatures B-40 °C, C- 50 °C, D-60 °C, E-70 °C, F-80 °C, G-90 °C and H-100 °C. |

It can be seen from the table that the viscosity of corn oil decreases with increasing temperature and shear speed. At high shear speeds, the viscosity of the oil remains constant.

Table 1: The results of rheological measurements for corn oil at increased shear rates

|

Shear rate, s-1 |

40°C |

50°C |

60°C |

70°C |

80°C |

90°C |

100°C |

|

Shear stress, Pa |

Shear stress, Pa |

Shear stress, Pa |

Shear stress, Pa |

Shear stress, Pa |

Shear stress, Pa |

Shear stress, Pa |

|

|

3.3 |

101.6400 |

72.8310 |

58.7400 |

55.9350 |

30.6240 |

29.7660 |

28.7430 |

|

6 |

161.7000 |

95.1600 |

84.4800 |

81.3000 |

78.1200 |

76.7400 |

74.9400 |

|

10.6 |

251.4320 |

150.9440 |

140.7680 |

130.8040 |

120.8400 |

114.1620 |

110.9820 |

|

17.87 |

389.3873 |

233.2035 |

219.9797 |

206.7559 |

193.5321 |

180.3083 |

167.0845 |

|

30 |

638.7000 |

356.7000 |

339.9000 |

323.1000 |

306.3000 |

289.5000 |

272.4000 |

|

52.95 |

1081.2390 |

570.8010 |

545.9145 |

521.0280 |

496.1415 |

471.2550 |

445.8390 |

|

80 |

1632.000 |

858.4000 |

816.0000 |

773.6000 |

731.2000 |

664.8000 |

644.8000 |

|

120 |

– |

1264.8000 |

1182.0000 |

1099.2000 |

1023.6000 |

948.0000 |

788.4000 |

Figures 2-4 show the dependence of the dynamic viscosity on the shear speed, respectively the log of the dynamic speed against on the log of the shear speed.

|

Figure 2: The dependence dynamic viscosities – shear rates at different temperatures B-40 °C, C- 50 °C, D-60 °C, E-70 °C, F-80 °C, G-90 °C and H-100 °C. |

|

Figure 3: A log-log plot of viscosity versus shear rate of figure 2. |

|

Figure 4: A log-log plot of viscosity versus shear rate of figure 2 at temperatures 40°C |

The figure shows a very good linearity of the data and the equation obtained by linear regression is expressed as:

log ƞ = 1.67673 – 0.40245 log

with a very good value of correlation coefficient (r = 0.99286) and a standard deviation SD = 0.02657.

Figure 5 shows the dependence of dynamic viscosity on temperature for low shear rates as 3.3s-1, 6s-1 and 10.6s-1. The viscosity of corn oil decreases with increasing temperature due to the orientation of the oil molecules.

|

Figure 5: Variation of viscosity with temperature at different shear rate as 3.3s-1, 6s-1 and 10.6s-1 for corn oil. |

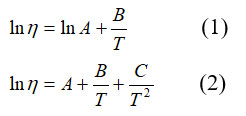

To support our results regarding the variation in viscosity depending on temperature, the Andrade equation (1) and the Azian equation (2) 12-16 were used:

Table 2: Parameters of the Andrade equation

|

Shear rate, s-1 |

Value of parameters of the described by equation Andrade |

R2 |

|

|

A |

B |

||

|

3.3 |

-4.9816 |

2625.6311 |

0.96784 |

|

6 |

-2.0283 |

1656.1019 |

0.99576 |

|

10.6 |

-1.9884 |

1600.9316 |

0.99196 |

|

17.87 |

-2.2789 |

1668.5066 |

0.99533 |

|

30 |

-2.3967 |

1707.6516 |

0.99878 |

|

52.95 |

-2.6264 |

1776.6710 |

0.99873 |

|

80 |

-2.6887 |

1779.9461 |

0.99984 |

|

120 |

-0.7790 |

1024.6746 |

0.9492 |

From table 1 it can be seen that the parameter A decreases at low shear rates and remains almost constant at high shear rates. Parameter B with increasing shear rate approaching unity. The correlation coefficients have values close to unity.

Table 2 shows the parameters of the Azian equation applied to the studied corn oil. Parameter A of the equation decreases with increasing shear speed, parameter B approaches the zero value, and parameter C increases with increasing shear speed. The correlation coefficients have values close to unity.

Table 3: Parameters of the Azian equation

|

Shear rate, s-1 |

Value of parameters of the described by equation Azian |

R2 |

||

|

A |

B |

C |

||

|

3.3 |

10.7517 |

-0.0221 |

-4.49107E-6 |

0.94128 |

|

6 |

24.7091 |

-0.1147 |

1.47912E-4 |

0.99934 |

|

10.6 |

25.2414 |

-0.1186 |

1.53445E-4 |

0.9997 |

|

17.87 |

21.0494 |

-0.0937 |

1.15816E-4 |

0.9995 |

|

30 |

11.1425 |

-0.0348 |

2.85875E-5 |

0.99956 |

|

52.95 |

6.2486 |

-0.0058 |

-1.43982E-5 |

0.99963 |

|

80 |

14.2905 |

-0.0537 |

5.61732E-5 |

0.99958 |

|

120 |

4.7011 |

-0.0080 |

2.37143E-6 |

0.99972 |

Conclusion

This study focuses on the variation of dynamic viscosity with temperature and shear rate for corn oil.

It was noted that the viscosity decreases with increasing shear rate and temperature. A significant decrease in viscosity is recorded at low shear rates.

Corn oil has a pseudoplastic behavior throughout the temperature range at which it was studied.

References

- Dupont J., White P.J., Carpenter M.P., Schaefer E. J., Meydani S.N., Elson, C.E., … & Gorbach S.L., 1990, Journal of the American College of Nutrition, 9(5), 438-470.

CrossRef - Veljković V.B., Biberdžić M.O., Banković-Ilić I.B., Djalović I.G., Tasić M.B., Nježić Z.B., & Stamenković O.S., 2018, Renewable and Sustainable Energy Reviews, 91, 531-548.

CrossRef - Strocchi A., 1982, Journal of Food Science, 47(1), 36-39.

CrossRef - Cerqueira M.A., Souza B.W., Teixeira J.A., & Vicente A.A., 2012, Food hydrocolloids, 27(1), 175-184.

CrossRef - Stanciu I., 2019, Journal of Science and Arts, 3(48), 703-708.

- Stanciu I., 2019, Journal of Science and Arts, 4(49), 938-988.

CrossRef - Stanciu I., 2011, Journal of Science and Arts, 1, 55-58.

- Stanciu I., 2018, Journal of Science and Arts, 18(2), 453-458.

- Ostlund Jr R.E., Racette S.B., Okeke A., & Stenson W.F., 2002, The American journal of clinical nutrition, 75(6), 1000-1004.

CrossRef - Sultana B., Anwar F., Asi M.R., & Chatha S.A.S., 2008, Grasas y aceites, 59(3), 205-217.

- Moreau R.A., Johnston D.B., Powell M.J., & Hicks K.B., 2004, Journal of the American Oil Chemists’ Society, 81(11), 1071-1075.

CrossRef - Rodenbush C. M., Hsieh F. H., Viswanath D. S., 1999, J. Am. Oil Chem. Soc., 76-141.

CrossRef - Krisnangkura K., Yimsuwan T., Pairintra R., 2006,Fuel, 85-107.

CrossRef - Esteban B., Riba J. R., Baquero G., Rius A., Puig R., 2012, Biomass and Bioenergy, 42, 164-171.

CrossRef - Perez A.T., 2010, Characterisation of the rheological properties of lubricants for EHL film thickness prediction, TriboUK, ImperialCollege, London.

CrossRef - Azian M.N., Kamal A.A.M., Panau F., Ten W.K., 2001, J. Am. Oil Chem. Soc., 78, 1001.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.