Rheology of Non-Additive Olive Oil used as a Biodegradable Lubricant

University of Bucharest, Faculty of Chemistry, Department of Physical Chemistry, 4-12 Elisabeta Blvd, 030018, Bucharest, Romania.

Corresponding Author E-mail: istanciu75@yahoo.com

DOI : http://dx.doi.org/10.13005/ojc/380528

Article Received on : 16 Aug 2022

Article Accepted on : 04 Oct 2022

Article Published : 12 Oct 2022

Reviewed by: Dr. Noureddine Ouerfelli

Second Review by: Dr. Tirsoaga alina

Final Approval by: Dr. Melody anak Kimi

In this article we studied the olive oil extracted from the cold pressed fruits and separated by centrifugation. The rheological models found in the literature for the dependence of the shear rate on the shear stress are: the Herschel – Bulkley model, the Ostwald model and the Bingham model. By linearizing the obtained data, we found two models that describe the behavior of the oil at the temperatures at which the olive oil was studied. Olive oil has a non-Newtonian behavior.

KEYWORDS:Non-Additive; Oilve; Oil; Rheology

Download this article as:| Copy the following to cite this article: Stanciu I. Rheology of Non-Additive Olive Oil used as a Biodegradable Lubricant. Orient J Chem 2022;38(5). |

| Copy the following to cite this URL: Stanciu I. Rheology of Non-Additive Olive Oil used as a Biodegradable Lubricant. Orient J Chem 2022;38(5). Available from: https://bit.ly/3EA2Lmt |

Introduction

Olive oil (the fruit of Olea europaea; family Oleaceae) is extracted from olives through a very simple process: the fruits are cold-pressed to extract the oil. Modern methods also involve crushing and mixing the olives, then separating the oil from the pulp by centrifugation.

After centrifugation, small amounts of oil remain in the olive cakes – this can be extracted using chemical solvents and is known as olive cake oil. After the recording of the rheograms, a delicate stage follows, namely their interpretation. There are many rheological models for interpreting data. For most fluids, the most widely used model is a three-parameter model, described by the Herschel – Bulkley equation 1–5:

In this model, τo represents the voltage or the effort of flow, signifying the minimum voltage that must be applied to initiate the flow. Obviously, being a voltage it is measured in Pascali (1 Pa = 1 N. m-2). K is the consistency coefficient, the value of which depends on the nature and temperature of the fluid. It is measured in Pa. sn, formally being a viscosity. The flow behavior index is the exponent of the shear rate, n. It is a dimensionless quantity, which depends on the nature of the fluid, its value being very little influenced by temperature.

The Herschel-Bulkley model is simplified and will take the form of the Ostwald model or the law of power:

Fluids for which the flow behavior index is unitary, as in Newtonian fluids, but there is flow effort (or tension) ( τo > 0) they are called plastic fluids or Bingham plastic. For such a material, its behavior is like an elastic solid when the stress is below the value of the flow stress (or stress) τo. For voltages greater than the flow voltage, the mathematical expression for the model is 6–8:

This mathematical expression of the Bingham model derives from the Herschel – Bulkley equation when n = 1, and K = η p. Given that the flow behavior index is unitary, the unit of measurement for the consistency index (K) is Pa. that is, the unit of measurement for viscosity. This is why K is replaced by η p 9–12.

Material and methods

Cold pressed olive oil was studied with the Haake VT 550 viscometer at increasing shear rates. From the dynamic viscosity and the shear rate, we determined the shear stress at each temperature. By linearizing the data obtained experimentally, we determined two rheological models that faithfully describe the behavior of olive oil.

Results and discussion

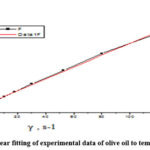

Figures 1-7 show linear fitting of experimental data of non-additive olive oil used as a biodegradable lubricant. As can be seen in the rheograms, the shear stress increases with increasing shear rate and has a linear dependence.

|

Figure 1: Linear fitting of experimental data of olive oil to temperature 313K. |

|

Figure 2: Linear fitting of experimental data of olive oil to temperature 323K. |

|

Figure 3: Linear fitting of experimental data of olive oil to temperature 333K. |

|

Figure 4: Linear fitting of experimental data of olive oil to temperature 343K. |

|

Figure 5: Linear fitting of experimental data of olive oil to temperature 353K. |

|

Figure 6: Linear fitting of experimental data of olive oil to temperature 363K. |

|

Figure 7: Linear fitting of experimental data of olive oil to temperature 373K. |

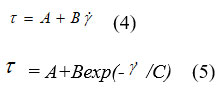

The article proposes two equations obtained by linear and exponential fitting of the experimental data:

Table 1: Rheological parameters of the model (4) for olive oil.

|

Temperature, K |

Rheological model constants (4) |

R2 |

|

|

A |

B |

||

|

313 |

40.8707 |

19.8184 |

0.9999 |

|

323 |

45.5434 |

11.2528 |

0.9995 |

|

333 |

38.8396 |

9.6028 |

0.9997 |

|

343 |

38.9844 |

8.9793 |

0.9994 |

|

353 |

38.2732 |

8.4015 |

0.9989 |

|

363 |

39.5068 |

7.7240 |

0.9989 |

|

373 |

33.0540 |

7.5880 |

0.9996 |

Table 2: Rheological parameters of the model (5) for olive oil.

|

Temperature, K |

Rheological model constants (5) |

R2 |

||

|

A |

B |

C |

||

|

313 |

-2.1256E7 |

2.1256E7 |

-1.0726E6 |

0.9999 |

|

323 |

8226.2569 |

-8194.2029 |

667.7298 |

0.9995 |

|

333 |

-9428.5756 |

-9428.5756 |

921.9126 |

0.9997 |

|

343 |

5055.5401 |

-5031.0308 |

499.1903 |

0.9998 |

|

353 |

3581.1580 |

-3561.7138 |

361.8749 |

0.9999 |

|

363 |

3159.7222 |

-3138.4422 |

344.0841 |

0.9998 |

|

373 |

5327.3930 |

-5303.8596 |

638.4288 |

0.9999 |

Applying model (4), the R2 have values between 0.9989 and 0.9999, which demonstrates that this model correctly describes the rheological behavior of unadditive olive oil used as a biodegradable agent.

Model (5) has the values of the R2 between 0.9995 and 0.9999, dedi and it correctly describes the rheological behavior of olive oil. The two models were obtained by linear and exponential fitting of the experimental data.

Conclusions

The article proposes two rheological models obtained by linear and exponential fitting of unadditive olive oil used as a biodegradable lubricant. The two models found faithfully describe the non-Newtonian behavior of unadded olive oil because R2 has values close to one. The olive oil was obtained by cold pressing and then the fruits were separated by centrifugation.

References

- Rao M.A. 1977, J. Text. Stud., 8, 257 – 282

CrossRef - Boger D.V. 1994, Yield stress measurement, Lecture Series 1994-03 “Non-Newtonian Fluid Mechanics”, Von Karman Institute for Fluid Mechanics, Belgium, February 21-25, 24.

- Ma L., Barbosa-Canovas G.V., 1993, Revista Espaniola de Ciencia y Tecnologia de Alimentos, 33(2), 133 – 163

- Holomb D.N., Tung M.A. 1991. Rheology, chapter in “Encyclopedia of Food Science and Technology”, volume 4, John Wiley and Sons, Inc., 2258-2264

- Velez-Ruiz J.F., Barbossa-Canovas G.V. 1997,, Critical Reviews in Food Science and Nutrition, 37(4), 311 – 359

CrossRef - Kokini, J.L. 1992. Rheological properties of foods, cap. 1 în “Handbook of Food Engineering” (D.R. Heldman, D.B. Lind, eds.), Marcell Dekker, New York, 1 – 38

- Schowalter, W.R., Christensen, G. 1998, J. Rheol., 42(4), 865-870

CrossRef - Dimonte, G., Nelson, D., Weaver, S., Schneider, M., Maudlin, F., Gore, R., Baumgardner, J.R. 1998, J. Rheol., 42(4), 727-742

CrossRef - Stanciu I., 2019, Journal of Science and Arts, 3(48), 703-708.

CrossRef - Stanciu I., 2019, Journal of Science and Arts, 4(49), 938-988.

- Stanciu I., 2011, Journal of Science and Arts, 1, 55-58.

- Stanciu I., 2018, Journal of Science and Arts, 18(2), 453-458.

This work is licensed under a Creative Commons Attribution 4.0 International License.