Mechanical Performance Efficiency and Wear Coefficient of PLA-HAZrO2 in Bones Replacements

1Al-Karkh University of Science, College of Science, Haifa Street, Baghdad, Iraq.

2Department of Physics, College of Science, Muthanna University, Al-Muthanna, Samawa, Iraq.

Corresponding Author E-mail: hajasafa@yahoo.com

DOI : http://dx.doi.org/10.13005/ojc/350319

Article Received on : 20-04-2019

Article Accepted on : 02-06-2019

Article Published : 20 Jun 2019

In the current study, biological polymer base polylactic acid (PLA) composites subsidized with biphasic ceramic powder (HAZrO2) was prepared and developed using active mechanical mixing method. Hydroxyapatite (HA) with size of 52nm was mixed with zirconium dioxide with size of 42 nm at 1:1 mixing proportion via ceramic ball mill (350 rpm for four hours). The prepared sample was mixed with polymeric powder at (0%, 2%, 4%, 6% and 8%) weight percentage ratio. Afterwards, fluidic mixing and ultrasonic waves methods were used to synthesize the final nanocomposites. Pin-On-Disc method was used to measure wear and the results outputted high advisable nanocomposites with reactance to the cankering compared to PLA alone. Vickers microhardness investigations appear demonstrably acceptable and with exponential enhancement with the incrementing percentage ratio of reinforcing materials. In addition, Young modulus and the absorption energy tests (using Charpy method) showed a high improvement in the mechanical properties of the reinforced n-HAZrO2 powder. All the results were obtained depending on the homogeneous distribution of the nanopowder using both Scanning Electron Microscope (SEM) and Energy Dispersive X-ray (EDX) techniques.

KEYWORDS:Bones Replacements; Biomaterials; PLA; Wear

Download this article as:| Copy the following to cite this article: Farhan F. K, Odah J. F, Mohamed A. N. Mechanical Performance Efficiency and Wear Coefficient of PLA-HAZrO2 in Bones Replacements. Orient J Chem 2019;35(3). |

| Copy the following to cite this URL: Farhan F. K, Odah J. F, Mohamed A. N. Mechanical Performance Efficiency and Wear Coefficient of PLA-HAZrO2 in Bones Replacements. Orient J Chem 2019;35(3). Available from: https://bit.ly/2XZOWG0 |

Introduction

A biomaterial is any substance that has been engineered to interact with biological systems for medical purposes such as treating, augmenting, repairing or replacing a tissue function of the body or a diagnostic one. Biomaterials science encompasses elements of medicine, biology, chemistry, tissue engineering and material science.

Biomaterials can be obtained from nature or can be synthesized in the laboratory by adopting various chemical approaches using metallic components, polymers, ceramics, or composite materials.

In 1969, L.L. Hench et al found that various types of ceramics and glasses might be joined with living bone.1,2 Ceramics are nowadays used widely in medical applications such as bone implants and dental.3,4 The ceramic-polymer compsites were a possible method of filling cavities that replace amalgams that are suspected to include effects that are toxic.5

Vitreous carbon is used as light and compatible with blood and resistant to wear. In addition, it is used as a replacement of cardiac valve. An amalgam of composite materials that are mineral-organic such as titanium or alumina dioxide with the biocompatible polymers such as PMMA or PLLA could be more prevalent in the future due to their aptitude at combining a biological activity with mechanical properties similar to those of the bone.6

Darmawati M.Y. et al designed a bone tissue based on bioceramics and bioactive glasses.7 In addition, biological responses bioactive glass ceramics to products that are ionic was demonstrated Alexander Hoppe et.al.8

In 2014, Jaime Esteban et.al reported that zirconia ceramics showed significant enhancement over existing materials related to its resistance to wear, reduction, roughening, and biocompatibility.9

In 2016, Zou et al reported using a zinc calcium phosphate coating on a new class magnesium biodegradable to improve the homocompatibility.10

Batool J.O. et al was enhanced the mechanical characteristics of PMMA-ZrO2 system by increasing reinforced material (zirconia) ration compared with pure PMMA.11

The composites merge a phase of reinforcement polymer with a ceramic matrix to create materials with characteristics that are superior and new to ceramic and polymer. In this study, PLA-HAZrO2 nanocomposites were prepared using active mechanical mixing method. The mechanical characteristics were carried out on the sample that is final and can be used replacement of teeth and bones.

Theoretical Part

Hardness is the force of each penetration or indentation unit area and it is widely used to investigate plastic deformation. The hardness test is very important to estimate the materials performance when scratched. There are many hardness tests used in the current study, Vickers microhardness is calculated through the equation.12

Where p is the applied load and d is the each diameter.

Mechanical impact strength of bone materials is considered as an evidence for fracture resistance and impact energy absorption. Hence, this test is applied on the bone material -PMMA and the prepared nano-composites – as standard samples of (55, 10 and 10mm) without crack.

The following equations were used to calculate the absorption energy E(J), the fracture strength (solidity) I.S and toughness strength K.S.13

E(J) = mR (cosβ – cosα) … … … … … … (2)

Where α = 150° and mR = 75J is the pendulum energy.

where A is the sample area and E is Young modulus and it was obtained through the equation.

where σ is the stress, ∈ is the strain, P is the pressure, ΔL is the change in the length of the sample and L0 is the initial length.

Experimental Part

Active mechanical mixing method was used to prepare HAZrO2 powder, where 1:1 molar ratio of ZrO2 (42nm) and HA (52nm), which is equivalent to 64% of HA and 36% of ZrO2 as weight percent was incorporated. About 10gm of the obtained powder divided as 6.4gm of HA and 3.6gm of ZrO2 was mixing up with 20 ball and deposited in the ceramic crisply on a ball milling with 300rpm for 6 hours (dry mixing) to get a homogenous powder. The final powder resulted from the last step was thermally treated for two hours under 1000°C at 10°C/min.

Structural properties of final sample after calcination were investigated using EDX, SEM and XRD techniques.

The new powder was reinforced with PLD as 2%, 4%, 6% and 8% weight ratio using fluidic mixing and ultrasonic technique to obtain PLA-HAZrO2 nanocomposites. Finally, Vickers microhardness and mechanical impact strength for these composites was calculated.

Results and Discussion

Figure (1) shows the XRD pattern for the prepared powder utilized to strengthen PLA polymer.

|

Figure 1: XRD for PLA-HAZrO2 powder. |

Figure (1) shows the highest peaks at 2Ɵ=29° and 2Ɵ=31.8°,which indicates that the elements has interacted and formed the required compound. The peak at 2Ɵ=31.8° is an indication of HA , while ZrO2 appears at the angle 2Ɵ=51.01°. The leftover peaks refer to form (HAZrO2) nanocomposite which resulted from the amalgamating at 400°C.

Energy dispersive by X-ray (EDX) pattern is showing in figure (2).

|

Figure 2: EDX for PLA-HAZrO2 powder. |

Figure (2) shows the main elements that were mixed in order to form the mixed powder have interacted with each other to form a final compound. Table (1) deduced from the EDX pattern, which shows the weight percentage ratios for the compound components (HAZrO2), while Ca possesses the highest weight ratio followed by Zr and P has the lowest weight ratio, consecutively such: Ca:Zr=1:55, Zr:P=1:96 and Ca:P=3:6. The oxygen ratio kept constant.

Table 1: Compound components (HAZrO2) weight percentage ratios.

|

Element |

Wt% |

Wt% Sigma |

|

O |

42.81 |

0.82 |

|

Na |

0.45 |

0.15 |

|

Mg |

0.60 |

0.11 |

|

Si |

1.92 |

0.11 |

|

P |

8.26 |

0.32 |

|

Ca |

29.78 |

0.51 |

|

Zr |

16.19 |

0.74 |

|

: Total |

100.00 |

|

Figure (3) shows the scanning electron microscopy (SEM) imaging for nanobioceramics powder under 50Kx magnification.

|

Figure 3: SEM for PLA-HAZrO2 powder. |

Granular homogeneity between HA and ZrO2 is evident in SEM image, in addition to the combination between the granules to produce different figurations. SEM image emerges growing in forming granular size consequence to the calcination treatment, whereat the size was less than 80 nm.

Wear coefficient or wear average is defined as loss in surface of material during the dry sliding motion because of the friction between the sample’s surface and the surface of rotation disc of the device. In this work, wear coefficient test was done for nanocomposites with PLD polymeric basic using Pin-on-Disk under standard calculation (ASTM-G99).

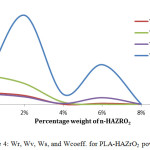

Different types of wear average such Wr, Wv, Ws and Wcoeff. are shown in figure (4).

|

Figure 4: Wr, Wv, Ws, and Wcoeff. for PLA-HAZrO2 powder. |

The experimental results accentuated that all tests are consubstantiality except Wcoeff. Which discorded from the remnant wears and the causation is the fineness in wear measuring and the implicitly of this measurement to the microhardness values and the experimental density for the preparing nanocomposites.

Figure (4) shows the enhancement in the wear with the gainfulness in percentage ratio of reinforced material (HAZrO2) due to the excess in the surface area of the powder and its high microhardness resulted from n-ZrO2 in HAZrO2 which proofed to the wear and friction.

At the ratio 4%, one can notice that all curves suffer the same downtrend for all types of wears and this may be ascribed to the power unisonous circulation within the polymer which gives surface alliterative microhardness and high resistance to the wear and corrodibility, this agree with.14

Note worthiness at that all curves start to climb from the ratio 4% accessing to the maximum value then start disembarking at the ratio of 8%, this may attributed to existence some air gaps entered the samples which resulted from the conglomerates within the polymer.

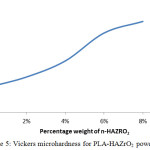

Figure (5) shows Vickers microhardness as a function to the percentage weight n-HAZrO2.

|

Figure 5: Vickers microhardness for PLA-HAZrO2 powder. |

The mechanical properties such Vickers microhardness is improved for the bioceramic PLA reinforced by HAZrO2, this is resulted from the consolidating material and its homogeneously distribution tacitly within the polymer. Vickers microhardness at 8% percentage weight ratio of n-HAZrO2 was more 80% compared with the unreinforced base (PLA). This improvement in microhardness may be caused by blocking the pores and holes in the polymer and increasing in density of reinforced composites, these reasons lead to high resistance to the scratching and wear.

Stress investigation was carried out using totally machine device under the standard characteristics (ASTM) for the prepared samples with dimensions (2x2x2cm). Figure (6) shows stress and Young modulus against the percentage weight of n-HAZrO2 for all samples.

|

Figure 6: Stress and Young modulus as a function of percentage weight of n-HAZrO. |

Figure (6) shows the strengthening composites with the bioceramics power are sturdier from ones without reinforcing, whereat as the percentage weight of powder incremented, both stress and Young modulus are increase and the samples withstand the external efforts, the raiser is that the powder absorbs all extern compressing and scatters it within the whole surface of sample.

The value of stress 85 MPa for PLA is subtends Y-modulus of 0.98GPa, while with reinforcing ratio of 8% both stress and Y-modulus increase to be 104.8 MPa and 2.1 GPa respectively. This denotes that the bioceramic powder used in the current study possesses more flexibleness than the polymer own itself, and this gives the composite material high overload-proof at load less than 104.8 MPa.

Figure (7) shows the absorption energy and the fracture strength (solidity) variation with the percentage weight of n-HAZrO2 respectively.

|

Figure 7: Absorption energy and fracture strength variation with the percentage weight of n-HAZrO2. |

Figure (7) indicates that the enhancement in the absorption energy and the fracture strength (Kc) for a prepared composites which reinforced by HAZrO2 powder compared with the base material (PLA). This may attributed to convert PLA from a brittle material to a solid one with high durability due to the reinforcing material which acted to improve PLA from dislocations and suddenly cleavages.

Conclusion

From precede; one can conclude that the active mechanical mixing method which used to prepare the bioceramic HAZrO2 powder is agreeable way to squirreling owner mechanical and biological characteristics of the prepared powder. These characteristics were expressed at the ratio 6% and less than this ratio rapidly and then resides and diminishing at ratio more than 6%.

From the results of mechanical tests, it can educed that the omnipotence of the prepared nanocomposites to be used as redemptive instead of bones and teeth alike.

References

- Hench, L. L. J. Am. Ceram. Soc. 1991, 74, 1487.

- Yamamuro, T.; Hench, L.L. Wilson, J. Journal of Biomedical Materials Research banner 1990, 25, 903-904.

- Muster, D. Biomaterials hard tissue repair and replacement, North-Holland, 1992.

- Kinnari, T. J.; Esteban, J.; Gomez‐Barrena, E.; Zamora, N.; Fernandez‐Roblas, R.; Nieto, A.; Doadrio, J. C.; López‐Noriega, A.; Ruiz‐Hernández, E.; Arcos, D.; Vallet‐Regí, M. journal biomedical materials research 2008, 89, 215-223.

- Boch, P.; Niepce, J. C. Ceramic Materials: Processes, Properties and application, United States, ISTE Ltd, 2007.

- Thamaraiselvi, T. V.; Rajeswari, S. Trends Biomater. Artif. Organs, 2004, 18, 9-17.

- Younos, D. M.; Bretcanu, O.; Boccaccini, A. R. Journal of materials science, 2008, 43 4433-4442.

- Hoppe, A.; Güldal, N. S.; Boccaini, A. R. Biomaterialsm, 2011, 11, 2757-2774.

- Esteban, J.; Gomez-Barrena, E. Microbiology for surgical infections, Academic Press, 2014, 324.

- Mulinti, A.E. Hemocompatibility of Biomaterials for clinical applications, Woodhead Publishing 1st Edition, 2017, 253-278.

- Obead, B.; Farhan, K.; Mohammed, J. E. Jour.of adv. Research and controlling systems, 2018, 10.

- Otsuka, T.; Chujo, Y. Polym. J., 2008, 40, 1157–1163.

- Poskus, L. T.; Placido, E.; Capel Cardoso, P. E. Dent Mater 2004, 20, 726-732.

- Farhan, F. K.; Kadhim, M. O.; Ashour, S. J. Journal of computational and theoretical nanoscience, 2019, 16, 1-6.

This work is licensed under a Creative Commons Attribution 4.0 International License.