Rheological Behavior of Biodegradable Lubricants

University of Bucharest, Faculty of Chemistry, Department of Physical Chemistry, 4-12 Elisabeta Blvd, 030018, Bucharest, Romania.

Corresponding Author E-mail: Istanciu75@yahoo.com

DOI : http://dx.doi.org/10.13005/ojc/350224

Article Received on : 02-01-2019

Article Accepted on : 22-03-2019

Article Published : 05 Apr 2019

Biodegradable lubricants are of particular interest from the point of view of environmental protection. Generally, base oils for biodegradable lubricants may be: polyglycols, synthetic ester oils and vegetable oils. The vegetable oils used in this study are: oil sunflower, soybean oil and coconut oil. The rheological study was based on graphical representation of shear velocity based on shear stress using experimental data. The rheological models found in the literature are: Bingham, Casson, Ostwald-de Waele and Herschel-Bulkley. The article proposes three other rheological models of shear speed dependence on shear speed.

KEYWORDS:Oil Coconut; Oil Soybean; Oil Sunflower; Rheology

Download this article as:| Copy the following to cite this article: Stanciu I. Rheological Behavior of Biodegradable Lubricants. Orient J Chem 2019;35(2). |

| Copy the following to cite this URL: Stanciu I. Rheological Behavior of Biodegradable Lubricants. Orient J Chem 2019;35(2). Available from: https://bit.ly/2YO9iCS |

Introduction

The rheological properties of oils depend on several factors including temperature, shear rate, concentration, density, pressure, application time, chemical properties, additives and catalysts, molecular weight, degree of unsaturation of fatty acids, melting point.1-3 Most research has focused on studying the effects of temperature, shear rate, concentration and pressure. The most important factor affecting viscosity is temperature. The viscosity of oils and fats decreases with.4,5 Wan Nik, Ani, Masjuki and Eng Giap6 evaluated the effects of shear rate and temperature on the rheological properties of sunflower, corn, canola, coconut and superolein vegetable oils. The effects of shear temperature and velocity were studied by comparing some parameters obtained through four rheological models. It has been found that the viscosity decreases with the increase in temperature at all the studied oils, the influence of the temperature on the change in viscosity being stronger than the effect of the shear rate. It has been established that sunflower oil has the best stability of viscosity with temperature variation. Heating and maintaining oils at high temperatures is a process that causes a series of chemical reactions that occur in the oil, generating a multitude of chemical compounds.7 Satyanarayana and Muraleedharan8 studied viscosity variation with temperature rise for palm kernel oil and rubber oil seed oil. In the case of oil from the rubber tree seeds, a more pronounced decrease of the viscosity with the temperature was observed than with the oil obtained from the palm kernels. In the paper,9 Campanela determined the viscosity variation with temperature and shear shear variation with the shear rate for sunflower oil, soybean oil, and high oleic sunflower oil. From the analysis of the obtained data it results that between the three oils there are very small differences in the viscosity evolutions with the temperature and the shearing stress with the shearing speed. A study10 on temperature viscosity variation for soybeans, sunflower, olives, peanuts, canola and corn has highlighted that soybean oil has the slightest variation in viscosity with temperature, followed by the corn, canola oil, hazelnut oil, sunflower oil, while olive oil has the largest variation. A comparative study of viscosity variation with temperature and shear rate for rapeseed oils obtained at various stages of manufacture was carried out in the papers.11 Different differences in viscosity variations with temperature and shear velocity were noted. Yilmaz12 analyzed the rheological behavior of sunflower oil, soybean oil, peanut oil and a vegetable oil of vegetable origin. At 20°C, peanut oil has the highest viscosity, followed largely by worn oil and sunflower oil, the lowest viscosity is obtained with soybean oil. With the increase in temperature, the difference between the viscosity of the peanut oil and the viscosity of the other oils is getting smaller and the differences in the viscosities of the four vegetable oils are insignificant at 120°C. In the literature, there are four shear stress shear patterns. These are13-14:

Bingham: t = to +η Ý (1)

Casson: t1/2 = to1/2 + η1/2 ý 1/2 (2)

Ostwald-de Waele: t = k n (3)

and Herschel-Bulkley: t = to + kηn (4)

where t is the shear stress, to – yield stress, η – viscosity, ý – shear rate, n – flow index and k – index of consistency.

The present paper comprises three shear stress shear stress equations for three types of oils in the temperature range 313-373K.

Material and methods

The rheological behaviour of oils (sunflower, soybean and coconut) was determined using a Haake VT 550 Viscotester developing shear rates ranging between 3 and 120 s-1 and measuring viscosities from 104 to 106 mPa.s when the HV1 viscosity sensor is used. The temperature ranged between 313 and 373K. The accuracy of the temperature was 0.1°C.

Results and Discussion

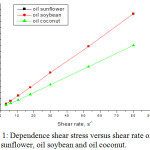

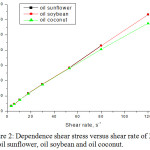

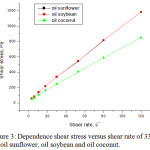

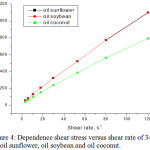

Figures 1, 2, 3, 4, 5, 6 and 7 show the shear shear shear shear shear shear in the temperature range 313-373K. The graphs show a linear shear stress shear rate at all the temperatures at which the three types of biodegradable oils were studied: oil soybean oil, sunflower oil and coconut oil.

|

Figure 1: Dependence shear stress versus shear rate of 313K for oil sunflower, oil soybean and oil coconut. |

|

Figure 2: Dependence shear stress versus shear rate of 323K for oil sunflower, oil soybean and oil coconut. |

|

Figure 3: Dependence shear stress versus shear rate of 333K for oil sunflower, oil soybean and oil coconut. |

|

Figure 4: Dependence shear stress versus shear rate of 343K for oil sunflower, oil soybean and oil coconut. |

|

Figure 5: Dependence shear stress versus shear rate of 353K for oil sunflower, oil soybean and oil coconut. |

|

Figure 6: Dependence shear stress versus shear rate of 363K for oil sunflower, oil soybean and oil coconut. |

|

Figure 7: Dependence shear stress versus shear rate of 373K for oil sunflower, oil soybean and oil coconut. |

This paper presents three shear stress shear stress ratios other than those found in the literature, applied to the experimental data for the three lubricating oils. Equation (5) shows the linear shear stress shear shear rate for the studied oils. Equation (6) shows the polynomial dependence of the shear stress on shear velocity and equation (7) shows the exponential dependence of the two sizes.

t = a+ b ý (5)

τ = a +b ý+c2 ý (6)

τ = τ0 +a exp(-ý/b) (7)

Table 1: Correlation constants for rheological model (eq.5) at different temperature ranging from 313 K to 373K for oil sunflower, oil soybean and oil coconut.

|

T(K) |

Oil sunflower |

Oil soybean |

Oil coconut |

||||||

|

a |

b |

R2 |

a |

b |

R2 |

a |

b |

R2 |

|

|

313 |

19.8184 |

40.8707 |

0.9999 |

19.8298 |

39.2877 |

0.9999 |

13.2248 |

40.2204 |

0.9999 |

|

323 |

10.1966 |

41.1761 |

0.9999 |

10.2058 |

40.7291 |

0.9998 |

9.3029 |

53.5341 |

0.9991 |

|

333 |

9.6028 |

38.8397 |

0.9997 |

9.6248 |

38.6389 |

0.9997 |

6.8709 |

35.2977 |

0.9996 |

|

343 |

8.9793 |

38.9844 |

0.9994 |

8.9593 |

38.9844 |

0.9994 |

6.4601 |

32.7716 |

0.9989 |

|

353 |

8.4015 |

38.2732 |

0.9989 |

8.4149 |

38.2984 |

0.9989 |

6.2037 |

33.5156 |

0.9984 |

|

363 |

7.7244 |

39.4742 |

0.9988 |

7.4829 |

44.6587 |

0.9975 |

6.0586 |

30.4246 |

0.9987 |

|

373 |

7.5876 |

33.0866 |

0.9997 |

7.3621 |

37.9352 |

0.9987 |

5.7591 |

31.3709 |

0.9985 |

Tables 1, 2, 3, 4, 5 and 6 show the correlation coefficients for the three equations, parameters a, b, c and t0 for sunflower, soybean and coconut oils in the temperature range 313-373K.

Parameter a of equation (5) decreases with increasing temperature in order of sunflower oil, soybean oil and the lowest values are for coconut oil.

Paraffin b in equation (5) decreases as the temperature increases with the order of sunflower oil, soybeans and the last one is coconut oil.

Table 2: Correlation constants for rheological model (eq.6) at different temperature ranging from 313 K to 373K for oil sunflower, oil soybean and oil coconut.

|

T(K) |

Oil sunflower |

Oil soybean |

||||||

|

a |

b |

c |

R2 |

a |

b |

c |

R2 |

|

|

313 |

19.3353 |

45.7115 |

0.0059 |

0.9999 |

19.4858 |

42.7344 |

0.0042 |

0.9999 |

|

323 |

10.2639 |

40.2711 |

-5.7430E-4 |

0.9997 |

10.1825 |

41.0424 |

1.9877E-4 |

0.9997 |

|

333 |

10.2066 | 30.7204 |

-0.0051 |

0.9997 |

10.2294 |

30.5093 |

-0.0052 |

0.9997 |

|

343 |

10.0254 | 24.9179 |

-0.0089 |

0.9998 | 10.0054 | 24.9179 |

-0.0089 |

0.9998 |

|

353 |

9.7546 | 20.0791 |

-0.0115 |

0.9999 |

9.7881 |

19.8339 |

-0.0117 |

0.9999 |

|

363 |

9.0146 |

22.1259 |

-0.0110 |

0.9998 |

9.4227 |

18.5760 |

-0.0166 |

0.9999 |

|

373 |

8.2755 |

23.8375 |

-0.0059 |

0.9999 |

8.6850 |

20.1464 |

-0.0113 |

0.9999 |

Parameter c in equation (6) has varable values in the temperature range in which the oils were studied.

Table 3: Correlation constants for rheological model (eq.6) at different temperature ranging from 313 K to 373K for oil coconut.

|

T(K) |

Oil coconut |

|||

|

a |

b |

c |

R2 |

|

|

313 |

12.8963 |

43.5113 |

0.0040 |

0.9999 |

| 323 |

10.6671 |

35.1924 |

-0.0116 |

0.9998 |

| 333 |

7.4791 |

27.1191 |

-0.0052 |

0.9999 |

| 343 |

7.5201 |

18.5188 |

-0.0090 |

0.9999 |

| 353 |

7.4381 |

16.9179 |

-0.0105 |

0.9998 |

| 363 |

6.9155 |

18.9028 |

-0.0073 |

0.9989 |

| 373 |

6.8045 |

17.3143 |

-0.0089 |

0.9994 |

The parameter τ0 in equation (7) has positive and negative values in the temperature range in which the three types of oils were studied. The values of all parameters depend on the chemical structure of the oil and their non-Newtonian behavior. Correlation coefficients have values close to the unit for all three equations and types of oils.

Table 4: Correlation constants for rheological model (eq.7) at different temperature ranging from 313 K to 373K for oil sunflower, oil soybean and oil coconut.

| T(K) |

Oil sunflower |

|||

|

a |

b |

τ0 |

R2 |

|

| 313 |

2.1255E7 |

-1.0725E6 |

-2.1255E7 |

0.9999 |

| 323 |

8627.1730 |

-88566.7122 |

88606.9697 |

0.9997 |

| 333 |

921.9126 |

-9428.5756 |

9459.1153 |

0.9997 |

| 343 |

499.1903 |

-5031.0308 |

5055.5401 |

0.9998 |

| 353 |

3581.1579 |

-3561.7138 |

3581.1579 |

0.9999 |

| 363 |

343.6805 |

-3135.5209 |

3156.7454 |

0.9998 |

| 373 |

639.8184 |

-5314.0908 |

5337.6778 |

0.9999 |

Table 5: Correlation constants for rheological model (eq.7) at different temperature ranging from 313 K to 373K for oil soybean.

| T(K) | Oil soybean | |||

|

a |

b |

τ0 |

R2 |

|

| 313 |

1.12732E6 |

-2.2355E7 |

2.2355E7 |

0.9999 |

| 323 |

184164.8537 |

-1.8801E6 |

1.8801E6 |

0.9997 |

| 333 |

923.0815 |

-9461.4239 |

9491.7546 |

0.9997 |

| 343 |

498.0696 |

-5009.8352 |

5034.3435 |

0.9998 |

| 353 |

357.3468 |

-3529.6679 |

3548.8614 |

0.9999 |

| 363 |

59.7904 |

-949.3085 |

912 |

0.9658 |

| 373 |

325.5386 |

-2856.4450 |

2875.9804 |

0.9999 |

Table 6: Correlation constants for rheological model (eq.7) at different temperature ranging from 313 K to 373K for oil coconut.

| T(K) | Oil coconut | |||

|

a |

b |

τ0 |

R2 |

|

| 313 |

1.21772E6 |

-1.6104E7 |

1.6104E7 |

0.9999 |

| 323 |

392.5387 |

-4226.5564 |

4260.9162 |

0.9998 |

| 333 |

654.6927 |

-4914.0213 |

4940.9153 |

0.9999 |

| 343 |

353.7665 |

-2686.8066 |

2704.7599 |

0.9999 |

| 353 |

288.2036 |

-2178.4783 |

2194.4185 |

0.9999 |

| 363 |

222.6809 |

-2147.1985 |

2164.1389 |

0.9999 |

| 373 |

61.8571 |

-736.1542 |

708.0000 |

0.9617 |

Conclusion

The vegetable oils used in this study are: oil sunflower, soybean oil and coconut oil. The rheological study was based on graphical representation of shear velocity based on shear stress using experimental data. The rheological models found in the literature are: Bingham, Casson, Ostwald-de Waele and Herschel-Bulkley. The article proposes three other rheological models of shear speed dependence on shear speed. The three oils have a non-Newtonian behavior within the timeframe in which they were studied.

References

- Revwolinski, C.; Shaffer, D. L.; Journal of the American Oil Chemisis ‘ Society 1985, 62, 1120-1124.

- Toro-Vazquez, J. F.; Infante-Guerrero, R.; Journal of the American Oil Chemisis ‘ Society 1993, 70, 1115-1119.

- Diaz, R. M.; Bernardo, M. I.; Fernandez, A. M.; Folgueras, M. B.; Fuel 1996, 75, 574-578.

- Eromosele, C. O.; Paschal, N. H.; Bioresour. Technol. 2003, 86, 203–205.

- Hasan, S. W.; Ghannamb, M.; Esmail, N.; Fuel 2010, 89, 1095–1100.

- Wan Nik, W.; Ani, F. N.; Masjuki, H. H.; Eng Giap, S. G.; Industrial Crops and Products 2005, 22, 249-255.

- Belitz, H. D.; Grosch, W.; Schieberle, P.; Food Chemistry, 4th revised and extended Edition, Springer-Verlag, Berlin, ISBN 978-3-540-69933-0, 2009.

- Satyanarayana, M.; Muraleedharan, C.; Energy 2011, 36, 2129-2137.

- Campanella, A.; Rustoy, E.; Baldessari, A.; Baltanas, M.; Bioresource Technology 2010, 101, 245-254.

- Franco, Z.; Nguyen, Q. D.; Fuel 2011, 90, 838-843.

- Ştefănescu, I.; Calomir C.; Gheorghieş, C.; Spânu, C.; The Annals of ”Dunărea de Jos” University of Galaţi, Fascicle VIII Tribologie 2005, ISSN 1221-4590, 3–7.

- Yilmaz, N.; Biomass and Bioenergy 2011, 35, 2936-2938.

- Stanciu I.; Oriental Journal of Chemistry 2015, 31(3), 1383-1387.

- Stanciu I.; Oriental Journal of Chemistry 2015, 31(4), 2017-2023.

This work is licensed under a Creative Commons Attribution 4.0 International License.