Treatment of contaminated Landfill Leachate using Aged Refuse Biofilter Medium

Iqbal K. Erabee and Saleem Ethaib

and Saleem Ethaib

Department of Civil Engineering, College of Engineering, University of Thi-Qar, Iraq.

DOI : http://dx.doi.org/10.13005/ojc/340334

Article Received on : April 18, 2018

Article Accepted on : May 02, 2018

Article Published : 15 Jun 2018

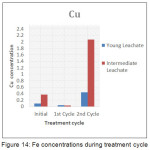

In this study, landfill leachate was treated in a biofilter filled with a mixture of aged refuse and gravel in the modified aged refuse (AR) biofilter column from square to cylindrical column by spraying the leachate over the surface of refuse in biofilter. The modified AR biofilter was evaluated for its performance in the treatment of landfill leachate from young waste cell of landfill (young leachate) and equalization lagoon (intermediate leachate) from sanitary landfill site. The hydraulic loading of 55 L/m3/d with 0.7 L.day-1 total leachate volume was sprayed over the refuse samples 2 times a day. The physical, chemical, and biological characteristics of AR were analyzed for evaluating the AR biofilter as leachate treatment host. The initial concentration of chemical oxygen demand (COD) and biochemical oxygen demand (BOD) for young and intermediate leachate is 4,800 mg/L, 1,260 mg/L and 6,400 mg/L, 1,125 mg/L respectively. After first cycle of treatment, the final effluent of young and intermediate leachate was inodorous and colorless with COD and BOD 800 mg/L, 60 mg/L and 1,600 mg/L, 120 mg/L respectively. The percentage of reduction is about 75%- 95%. The result relieved that over 85% of zinc (Zn), 96% if iron (Fe), 89% of cadmium (Cd), 82% of lead (Pb)and 91% of copper (Cu) were removed for intermediate leachate whereas 38% of Zn, 85% of Fe, 65% of Cd, 30% of Pb and 59% of Cu were removed for young leachate by first cycle of single stage AR biofilter when the initial concentration of heavy metals were 6.5493 mg/L (Zn), 79.0209 mg/L (Fe), 0.314 mg/L (Cd), 1.2114 mg/L (Pb), 0.368 mg/L (Cu) and 3.442 mg/L (Zn), 18.945 mg/L (Fe), 0.105 mg/L (Cd), 0.139 mg/L (Pb), 0.088 mg/L (Cu) respectively.

KEYWORDS:Aged Refuse; Biofilter; Heavy Metals; Landfills; Leachate Treatment

Download this article as:| Copy the following to cite this article: Erabee I. K, Ethaib S. Treatment of contaminated Landfill Leachate using Aged Refuse Biofilter Medium. Orient J Chem 2018;34(3). |

| Copy the following to cite this URL: Erabee I. K, Ethaib S. Treatment of contaminated Landfill Leachate using Aged Refuse Biofilter Medium. Orient J Chem 2018;34(3). Available from: http://www.orientjchem.org/?p=46667 |

Intorduction

Municipal Solid Waste (MSW) is waste type consisting of daily items discharged by the public. The Solid Waste and Public Cleansing Management Act 2007 indicate that these solid waste include commercial, household, institutional and public solid waste.1 Most of the MSW are disposed at landfill or dumpsite and only a small amount to incinerators. Alternatively, a modern sanitary landfill is not a dump, it is an engineered facility used for disposing of solid waste on land without hazards to public health, such the contamination of ground water.

It spreads the waste in thin layers, compacting it to smallest practical volume, and covers it with compacted soil.2 Yalcin and Demirer3 reported that by using this disposal method, the landfill constitution and management can be sufficiently developed to ensure that even large volumes of such materials can be handled and disposed in a way to protect public health and minimize adverse impacts on the environment. By using landfills, river water exposed to the risk of contamination from leachate unless proper leachate management is carried out.4

Previous studies conducted by several researchers in order to treat landfill leachate using low cost and available raw materials such as electrolysis process5 and adsorption process using agricultural waste activated carbon.6,7,8,9 Li10 characterized aged refuse in various stages of decomposition in order to use it in cost effective and environmental friendly treatment method. Thus, they found that the aged refuse (AR) can form as a material based in a biofilter because of its composition has a great composed and degraded material which helps in the treatment. The age refuse can be defined as waste from various material that has been disposed and buried into the landfill for a along period of time and the waste becomes stabilized as a result from anaerobic decomposition processes.

Landfill leachate have a high organic and inorganic content and also contain significant amounts of heavy metals due to disposal of metal containing wastes into sanitary landfills. The major problems is when the untreated leachates discharging to the environment or without fulfill the standard requirement from Environment Quality Regulations (EQR),11 the streams or waterways will be exposed to contaminants from leachates.

From previous study by Hong12 and Aziz,13 due to migration of leachates which contents elements in high concentration includes lead, zinc, copper, iron, manganese, chromium and cadmium. These heavy metals in solid wastes lead to serious problems because they cannot be biodegraded. However, removal of metals from leachate is not well documented, especially in Malaysia.14 Thus, this study focused on the effectiveness of the aged refuse biofilter to remediate leachate contaminated by heavy metals. The main objectives of this study are to determine the properties of leachate, age refuse and identify the heavy metals concentration in leachate and to investigate the effectiveness of heavy metals treatment process by using modified filtration column. Finally, to analyze the effluent characteristics of aged refuse in terms of number cycles.

Experimental

Sample Collection

Aged refuse (AR) sample (with 8 years of placement) was taken from Air Hitam Sanitary Landfill near the Air Hitam Forest in Puchong, Selangor, Malaysia. The sample of landfill leachate was collected from Jeram Sanitary Landfill (JSL) in Jeram, Kuala Selangor, Malaysia. The sample of leachate was chosen in two different phases in range of young ( 0-5 years) and intermediate (5-10 years) in order to investigate the properties and efficiencies of these leachates after undergoing the process of treatment by aged refuse.

|

Figure 1: Photograph of leachate sample collection from landfill |

The sample of aged refuse was pulverized into smaller pieces by hammer and immediately test for the moisture content and loss on ignition. Then, the refuse was dried naturally at room temperature to make sure that the leachate presence in the refuse totally dried. Larger non-biodegradable components such as stones, glass, bottles and plastic firms were removed from age refuse and then screened with diameter less than 15 mm.13 Particle sizes below 4 mm appear to best support bacterial communities.15 The gravel size of less than 10 cm was prepared for supporting materials and size of 10, 6 and 2 mm were mixed with the aged refuse.16

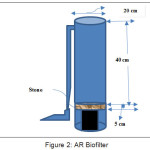

AR Biofilter

The biofilter is a lab-scale model, consisted of mixture of aged refuse and gravel as media and the leachate was spraying over the surface. The set-up of biofilter is shown in Figure 2. A cylindrical biofilter was used with an inner diameter of 20 cm and height of 50 cm, respectively. The surface area is 314 cm,3 with volume of dried and screened refuse of 12,566 cm.3 Three simulated biofilter columns were used in the experiment, two of them were filled with a mixture of aged refuse and gravel at a v/v ratio of 2:1. The rationale for the 2:1 mixture ratio is that higher percentage of age refuse might clog the column and higher percentage of gravel might prolong the microorganism’s growth time in the medium.16 A gravel layer about 5 cm thick was placed at the bottom of each column as a supporting material and above the medium layer of each column for leachate drainage and recycled leachate distribution.16 Another column was filled solely with gravel from various sizes (10, 6 and 2 mm, respectively) as a control system.

The leachate was sprayed over the surface of biofilters to make sure the refuse and leachate were mixed thoroughly. The hydraulic loading of 55 L/m3/d with 0.7 L.day-1 total leachate volume was sprayed over the refuse samples 2 times a day. The effluent was collected from the collection pipe and tested for physical, chemical and biological analysis. The study included tested of the parameters (pH, TSS, TDS, BOD, COD, microbial count, Zn, Fe, Mn, Cd, Pb and Cu). All experiments procedures were referred from Water and Wastewater Standard Methods. pH was analyzed using pH and TDS were analyzed using Tracer Pocketester (LaMotte, pH/TDS/Salt: TRACER POCKETTESTER TM (CODE 1766). Heavy metals such as Zn. Fe, Mn, Cd, Pb and Cu were analyzed using Calorimeter device (Calorimeter, HATCH DR/890, USA).

The effluent will be reuse for another cycle until the leachate reached the wastewater discharge standard. As the leachate seeped in the refuse, the organic pollutants in leachate will be first adsorbed and decomposed by greatly amount of microorganisms. Concentrations of COD, BOD and heavy metals in influent and effluent leachate were monitored and analyse according to the examination of water and wastewater method. The leachate samples was taken at every cycle with time interval of 5 days.

|

Figure 2: AR Biofilter Click here to View figure |

Results and Discussion

Sample Leachate Analysis

The physical appearance of leachate from landfill site is a strong odoured black colored liquid. The initial characteristics of young and intermediate leachate samples are shown in Table 1 and compared with Environment Quality Act1:

Table 1: Initial characteristics of young and intermediate leachate samples

| Parameter | Unit | Standard value | Young leachate | Intermediate leachate |

| Temperature | °C | 40 | 29.5 | 29 |

| pH | – | 6.0-9.0 | 8.01 | 8.08 |

| COD | mg/L | 400 | 4,800 | 6,400 |

| BOD | mg/L | 20 | 1,260 | 1,125 |

| Total Suspended Solid (TSS) | mg/L | 50 | 273 | 230 |

| Total dissolved Solid (TDS) | mg/L | 3,700 | 12,440 | 11,300 |

| Total microorganism count | CFU/1 00 ml | 107-1010 | 6.7×108 | 7.1×108 |

| Zn | mg/L | 2.0 | 3.4423 | 6.5493 |

| Fe | mg/L | 5.0 | 18.9450 | 79.0209 |

| Mn | mg/L | 0.20 | 0.6669 | 1.9476 |

| Cd | mg/L | 0.01 | 0.1051 | 0.3141 |

| Pb | mg/L | 0.10 | 0.1397 | 1.2114 |

| Cu | mg/L | 0.20 | 0.0882 | 0.3681 |

As seen in Table 1, the parameter evaluated include pH, BOD, COD, TSS, TDS, total microorganism count, heavy metals (Zn, Fe, Mn, Cd, Pb and Cu). Leachate had very organic content representing the first year of decomposition and reflected the characteristics of a young landfill. The initial pH of the leachates is 8.01, this is present weak alkaline. The value of BOD and COD are 1,260 mg/L and 4,800 mg/L respectively, which are high compared to the standard discharge value and this is correlated well to the reported BOD and COD ranges 1,000-57,700 mg/L and 1,500- 71,000 mg/L, respectively for acetogenic leachate typically from young landfill.17 Higher organic matter content is expected in this leachate due to generation of dissolved and solubilized organic matter. Meanwhile, the value for TSS and TDS are 273 mg/L and 12,440 mg/L, respectively which are considered very high compared to the standard value; 50 mg/L and 3700 mg/L, respectively. The number of microbes presence is 6.7×108CFU/ 100 ml and this value is considered high which indicated that the leachates rich organic matters for biological treatment.

Data for carbonaceous pollutants and other parameters in leachate from equalization lagoon are also depicted in Table 1. In lagoon samples the organic strength and heavy metals concentrations were higher than in sample taken from the young waste cell of landfill. The value of COD and BOD content are 6,400 and 1,125 mg/L, respectively. Whereas TSS and TDS are 230 and 11,300 mg/L, respectively, which are considered very high compared to the standard values given in Table 1.

Leachate Treatment Analysis Through AR Biofilter

The results of experimental work for leachate treatment are tabulated in Table 2. After the first cycle of treatment by aged refuse, most the parameters did not comply with the discharge limit except TSS (young leachate) and both TSS and TDS (intermediate leachate) and some of the heavy metals; Zn, Fe, Pb and Cu. Although it is above the standard limit, but still the effluent values for both samples are below the raw samples except for Mn. However, the effluent values are increase after the second cycle of treatment except for BOD for both samples and Fe in young leachate are continues decrease. It is recommended that longer time retention are required or different biofilter column used to treat leachate for different cycles to achieve the efficiencies of treatment for some parameters that were not complying with the standard (Table 1). It can be conclude that biological treatment by using aged refuse are effective for treatment of landfill leachate that can reduced all the parameters except Mn which is need different treatment process.

Table 2: Treatment of leachate sample from young waste cell of landfill (young leachate)

| Parameter | Unit | Standard value | Young leachate | ||

| 1 st Cycle | 2nd Cycle | ||||

| Temperature | °C | 40 | 27.5 | 28.7 | |

| pH | – | 6.0-9.0 | 6.58 | 6.80 | |

| COD | mg/L | 400 | 800 | 2,720 | |

| BOD | mg/L | 20 | 60 | 15 | |

| Total Suspended Solid (TSS) | mg/L | 50 | 36.7 | 85 | |

| Total dissolved Solid (TDS) | mg/L | 3,700 | 4,257 | 6.820 | |

| Total microorganism count | CFU/100 ml | 107-1010 | 3.5 × 107 | 2.5 × 107 | |

| Zn | mg/L | 2.0 | 2.143 | 5.202 | |

| Fe | mg/L | 5.0 | 2.900 | 1.385 | |

| Mn | mg/L | 0.20 | 3.225 | 5.156 | |

| Cd | mg/L | 0.01 | 0.036 | 0.038 | |

| Pb | mg/L | 0.10 | 0.097 | 0.496 | |

| Cu | mg/L | 0.20 | 0.036 | 0.442 | |

Table 3: Treatment of leachate sample from equalization lagoon (intermediate leachate)

| Parameter | Unit | Standard value | Intermediate leachate | ||

| 1 st Cycle | 2nd Cycle | ||||

| Temperature | °C | 40 | 28 | 28 | |

| pH | – | 6.0-9.0 | 7.01 | 8.12 | |

| COD | mg/L | 400 | 1,600 | 3,200 | |

| BOD | mg/L | 20 | 120 | 60 | |

| Total Suspended Solid (TSS) | mg/L | 50 | 33.3 | 200 | |

| Total dissolved Solid (TDS) | mg/L | 3,700 | 3,327 | 7,835 | |

| Total microorganism count | CFU/100 ml | 107-1010 | 4 × 107 | 1 × 107 | |

| Zn | mg/L | 2.0 | 0.962 | 10.470 | |

| Fe | mg/L | 5.0 | 3.138 | 7.525 | |

| Mn | mg/L | 0.20 | 3.166 | 3.011 | |

| Cd | mg/L | 0.01 | 0.033 | 0.112 | |

| Pb | mg/L | 0.10 | 0.220 | 1.406 | |

| Cu | mg/L | 0.20 | 0.034 | 2.070 | |

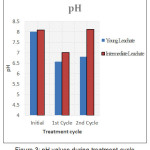

Figure 3 shows that pH at initial stage were about 8.01 and 8.08 for young and intermediate leachate respectively. After the treatment process, the pH for young and intermediate leachates decreased to about 6.58 and 7.01 in first cycle and was increased up to 6.58 and 8.12 in second cycle respectively. Even though the pH values were fluctuated, the values still in the range of 6.0-9.0 which complies with the standard discharge limit.

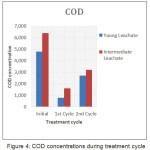

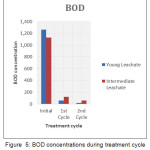

Figure 4 shows COD concentrations during treatment cycle for young and intermediate leachate. The COD value for intermediate leachate is relatively higher than young leachate. When the leachate being contact with the aged refuse in the biofilter, the COD concentration was decreasing in the first cycle of treatment about 83% and 75% for young leachate and intermediate leachate. However, the COD concentrations rise up in the second cycle of treatment for both leachate but still the COD values remain below the initial value of influent leachate. This was probably because of both AR biofilter contained low bacterial biomass after the first treatment. Figure 5 shows that the BOD concentration in young leachate influent was slightly high compared to the intermediate leachate. However, the BOD concentrations were dropped about 95% and 89% in the first cycle of treatment for young leachate and intermediate leachate respectively and continue decreasing in the second treatment below the standard limit. BOD concentrations for young and intermediate leachate were decreasing from 1260 mg/L 10 60 mg/L and 1125 mg/L to 120 mg/L in the first cycle and was dropped to 15 mg/L and 60 mg/L in the second cycle respectively indicating that the biodegradable organic matter were removed effectively.

|

Figure 3: pH values during treatment cycle Click here to View figure |

|

Figure 4: COD concentrations during treatment cycle Click here to View figure |

|

Figure 5: BOD concentrations during treatment cycle Click here to View figure |

As shown in Figure 6 the total suspended solids for young leachate and intermediate leachate were high as referred to standard discharge limit with value of 273 mg/L and 230 mg/L, respectively. The influent leachate was odorous and black and after the leachate passed through the AR biofilter, significant reduction in color was observed and the first treatment effluent was inodorous and transparent. The TSS value drastically dropped to the value of 36.7 mg/L and 33.3 mg/L for young and intermediate leachate respectively with average of 87% reduction. TSS concentration for first cycle was below the standard limit. Then the values drastically increased in the second treatment. This could happened because of the aged refuse considered to be dissolved substances and fine particle which was washed away during the leachate passing through the biofilter.

|

Figure 6: TSS concentrations during treatment cycle Click here to View figure |

Meanwhile Figure 7 show that TDS for young leachate was high compared to the intermediate leachate. At the initial phase, the value for TDS were 12,440 and 11,300 mg/L for young and intermediate leachate and decrease to 4,257 and 3,327 mg/L respectively with percentage of reduction about 66% – 71%. During second cycle of treatment, the value for TDS were increased, but still below the influent values.

|

Figure 7: TDS concentrations during treatment cycle Click here to View figure |

The value for microbial count for initial phase and after treatment process was depicted in Figure 8. The microbes in the influent of young and intermediate leachate contained 6.7 ×108 and 7.1 ×108 CFU/100 mL respectively. Then, the microbes were dropped in the first cycle of treatment for both samples which are 3.5 ×107 and 4 ×107 CFU/100 mL and continue decreasing in the second cycle of treatment ranging from 2×107 and 1 ×107 CFU/100 mL showing that the microbial growth has been stop and probably died because of lack in food.

|

Figure 8: Microbial contents in CFU/100 mL during treatment cycle Click here to View figure |

Meanwhile, the initial concentrations of heavy metals in these leachates are much above the discharge standard limit as shown in Figures 9, 10, 11, 12, 13 and 14. Based on the results in Table 2 and 3, these leachate have high concentration of heavy metals included Zn, Fe, Mn, Cd, Pb and Cu. AR biofilter has been used to treat the leachate contaminated by heavy metals and it is effective in removing some of heavy metals.

|

Figure 9: Zn concentrations during treatment cycle |

|

Figure 10: Fe concentrations during treatment cycle Click here to View figure |

|

Figure 11: Fe concentrations during treatment cycle Click here to View figure |

|

Figure 12: Fe concentrations during treatment cycle Click here to View figure |

|

Figure 13: Fe concentrations during treatment cycle Click here to View figure |

|

Figure 14: Fe concentrations during treatment cycle Click here to View figure |

Characterization of Biofilter Media- Aged Refuse

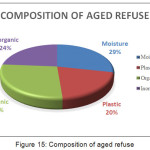

Aged refuse about 8 years old was excavated and the composition of the refuse (Figure 15) were determined to be 28.5% moisture, 20.2% plastic bags, bottles and other products, 27.6% organic matter such as trees, woods and cooking wastes and 23.7% inorganic matter such as stone, textiles, polystyrenes and glass bottles.

|

Figure 15: Composition of aged refuse Click here to View figure |

The biofilter media gives special characteristic as it act biologically for leachate treatment. Table 4 presents the basic characteristics of aged refuse before the treatment begin. The main physical, chemical and biological characteristics of AR were analysed to evaluate the AR biofilter as leachate treatment host.

Table 4: Characteristics of aged refuse before treatment

| Before Treatment (aged refuse) | ||||

| Aged refuse (years) | Moisture Content (%) | Microbial growth (CFU/ 100mL) | LOI * (%) | pH |

| 8 | 24.26-28.47 | 5.3 ×106 | 8.15 | 6.20 |

| * Loss on Ignition | ||||

With this percentage of moisture content (24.26-28.47 %), the aged refuse can be a perfect medium for the microbe to grow and enhance the biodegradation process for aerobic and anaerobic microbes. the population of microbes in aged refuse was 5.3 ×106 CFU/100 mL compared to the microbial quantities in raw leachate which have higher number of CFU/100mL. Loss on ignition analysis was used to determine the percentage of organic matter content in the aged refuse. By using the standard method to determine the LOI, the percentage of organic matter can be calculated by comparing the weight of the aged refuse before and after being ignited. The organic content in the 8 years aged refuse was 8.15%.

The initial pH for 8 years of aged refuse was 6.20 a shown in Table 4. This pH was considered to be slightly acidic as it contained high organic matter form during degradation mechanisms.

After all the process treatment has been done, the results obtained for the aged refuse are shown in Table 5. The sample was taken at the top and bottom of the aged refuse. The moisture content at the top of aged refuse reduces while at the bottom of it still contains high moisture content. Based on the observation in Table 5, the microbial growth in biofilter were increased from the top to bottom for the aged refuse used to treat he young leachate and intermediate leachate. Therefore, it can be said that changing in moisture content can be related with the growth of microorganisms in the aged refuse as the number of microorganisms increased as increasing of moisture content.

Table 5: Composition at the top and bottom of 8 years of aged refuse after treatment

| Type of leachate | Moisture content(%) | Microbial Growth(CFU/100 mL) | LOI(%) | pH |

| After treatment (top aged refuse) | ||||

| Young | 9.7 | 6.5 ×106 | 12.4 | 8.49 |

| Intermediate | 10.4 | 7.4 ×106 | 13.9 | 8.23 |

| After treatment (bottom aged refuse) | ||||

| Young | 13 | 7.9 ×106 | 10.9 | 9.26 |

| Intermediate | 14 | 8.3×106 | 11.3 | 9.07 |

As the leachate continuously passing through the biofilter, the microbes in the aged refuse that treat the young leachate and intermediate leachate slightly increase from 6.5 ×106 to 7.9 ×106 number of CFU/100mL (surface of the biofilter) and 7.9 ×106 to 8.3×106 number of CFU/100 mL (bottom of the biofilter) respectively. The numbers of microbes in the biofilter after the treatment process was much higher compared to the raw aged refuse after being collected from the landfill site.

The microorganisms in the biofilter help in leachate treatment as it is the biological treatment process that required the microbes to decompose the organic matter present in leachates. Therefore it can be concluded that aged refuse in biofilter can effectively treat leachate, biologically with large quantity of microbes.

As seen in Table 5, the organic matter content in aged refuse after treatment was slightly greater than the initial organic matter content. The organic matter value at the top of aged refuse (young leachate and intermediate leachate ) was 12.4% and 13.9% respectively. Meanwhile, at the bottom part of the aged refuse, the organic matter value slightly decreased to 10.9% and 11.3%. The results clearly show that the organic matter in aged refuse significantly higher that the initial values because of some organic matter in leachates had been absorbed by the aged refuse and degraded slowly.

Subsequently, after second treatment of leachate, the pH values for aged refuse began to increase from 6.20 into the weak alkaline in pH range from 8.23 to 9.26 for young and intermediate leachate. The fluctuation of pH levels at the top and bottom of the aged refuse might cause by the process that happen in the biofilter column during treatment process that contribute in changing the pH values.

Zhao15 has mentioned that the aged refuse may virtually degrade in biofilter when not stabilized to a great extent, which will contribute to increases of pollutant concentration in the effluent at the early stage of treatment. Based on the observation in figures and tables, it shows that the single treatment by using aged refuse was capable of removing all the parameters except the Mn that need further treatment.

Conclusion

Leachate treatment has been gained more attention from the researchers due to the relatively small flow rates and the complex leachate composition. Choosing of leachate treatment technology well depend on the main parameters of leachate such as BOD, COD and heavy metals. The 8 years of aged refuse used as an AR biofilter can be considered as achievable to remove all the parameters in the single stage into certain percentage below the initial value except Mn. At first, the leachate was odorous and black in colour turns to clear. Colourless and odourless. Meanwhile for the aged refuse, initially the color was light brown and after overall process of treatment the color become darken as the refuse contained great organic matter with finer fraction of size.

After the first treatment process, the aged refuse showed great potential in removing of COD, BOD, TSS, TDS and some of heavy metals in leachate include Zn, Fe, Cd, Pb and Cu. Removal of heavy metals occur mainly through adsorption and precipitation and by microorganism.

With all analysis done in this research, it can be concluded that the biological methods that used aged refuse are very effective for treatment of landfill leachate in a single stage.

Acknowledgements

The support of Ministry of Higher Education and Scientific Research in Iraq is acknowledged.

References

- Solid Waste and Public Cleansing Management Act, 2007. Act 672. Retrieved October 2013 from http://www.kpkt.gov.my/kpkt_2013/akta/Act672y2007bi.pdf.

- Corbitt, R.A., Standard Handbook of Environmental Engineering. McGraw Hill, NY.1989.

- Yalcin, F. and Demirer, G.N., Environmental Geology. 2002. 42,793-799.

CrossRef - Erabee IK, Ahsan A, Jose B, Aziz MMA, Ng AWM, Idrus S, Daud NNN. KSCE Journal of Civil Engineering. 2017, 22 (4), 1-13. https://doi.org/10.1007/s12205-017-1430-z

CrossRef - Erabee IK, Ahsan A, Jose B, Arunkumar T, Sathyamurthy R, Daud NNN, Idrus S. J. of Env. Science and Health (Part A). 2017, 52 (8),735-741. http://dx.doi.org/10.1080/10934529.2017.1303309

CrossRef - Ahsan A., Erabee IK, Jose B, Imteaz M, Idrus S, Daud NNN., Proc. Intl Conf. on water: from pollution to purification (ICW 2016). Dec 12-15, 2016, 79-80 at Mahatma Gandhi University, Kottayam, Kerala, India. http://www.ctamgu.in/icw2016/index.html

- Zhou, Xianzheng and Zhou, Jonathan Sanders and Mandapaka, Bhaskar Karonis-HPC and Papka–RDI, Marathe Amrut and Karonis–RDI, Boley Joshua and Papka, Ismail Sohail, Arbor, 2015. 1001, 48109-5948.

- Erabee IK, Ahsan A, Daud NNN, Idrus S, Shams S, Md Din MF, Rezania S., BioResources, 2017; 12(1), 1916-1923.. http://dx.doi.org/10.15376/biores.12.1.1916-1923.

CrossRef - Erabee IK, Ahsan A, Zularisam AW, Idrus S, Daud NNN, Arunkumar T, Sathyamurthy R, Al-Rawajfeh A. Engineering Journal, 2017. 21(5), 1-14. http://dx.doi.org/10.4186/ej.2017.21.5.1

CrossRef - Li, H.Gu, Y., Zhao, Y. and Wen, Z., Journal of Environmental Sciences, 2010. 128 (7), 662-668.

- Environmental Requirements. A Guide for Investors: Environmental Quality; 2009 (PU(A)433). Department of Environment Ministry of National Resources and Environment, Eleventh Edition.

- Hong, K.J., Tokunaga, S., Kajiuchi, T., Chemosphere, 2002. 49, 379-387.

CrossRef - Aziz, H.A. Yussuff, M.S., Adlan, M.N., Adlan, N.H., Alias, S., Waste Management, 2004. 24, 353-358.

CrossRef - Zhao, Y., Song, L., Huang, R. Song, L., Li, X., Waste Management and Research, 2005. 25, 130-138.

CrossRef - Zhao, Y.C., Li, H., Wu, J., Gu, G.W., J. of Environment Engineering, 2002. 128 (7), 662-668.

CrossRef - Xie, B., Bao, Y.L., Chong, H. Shao, B. L., Yuan, T., Jun, L., Bioresources Technology, 2010. 101, 7754-7760.

CrossRef - McBean, E.A., Rovers F.A., and Farquhar G.J., Solid Waste Landfill Engineering and Design, Prentice Hall PTR, Englewood Cliffs, 1995.

This work is licensed under a Creative Commons Attribution 4.0 International License.