Kinetic Studies of Sorption Separation of Phosphorus with Usage of Sorbents on the Basis of Natural Clays

A. S. Tleuov, S. D. Arystanova , S. T. Tleuova, A. A. Bolysbek, O. P. Baiysbay and A. S. Abzhanova

, S. T. Tleuova, A. A. Bolysbek, O. P. Baiysbay and A. S. Abzhanova

M.Auezov South Kazakhstan State University, Shymkent, Republic of Kazakhstan.

Corresponding Author E-mail: Jasiko2008@mail.ru

DOI : http://dx.doi.org/10.13005/ojc/340335

Article Received on : March 04, 2017

Article Accepted on : April 30, 2017

Article Published : 06 May 2018

Kinetic researches of sorption separation of phosphorus from phosphorus sludge with usage of sorbents on the basis of native silica-alumina clays in the low-temperature area are limited with adsorption processes and sublimation. Bentonites, vermiculites and refractory clays are chosen for carrying out researches. The high-quality sorbents resistant to work in an aqueous and aggressive environment are obtained on their basis. In practical conditions the kinetics process can be defined not only by the speed of actually chemical reaction of nucleation or internal diffusion, but also with other phenomena. When the most slow stage of chemical interaction in the mix solid – fluid – gas is recrystallization and adsorption that is characteristic for our researches, naturally change of sorption speed defines kinetics of interaction system.

KEYWORDS:Kinetics; Phosphorus Sludge; Sorbent; Sorbtion; Alumina Silicate; Activation Energy

Download this article as:| Copy the following to cite this article: Tleuov A. S, Arystanova S. D, Tleuova S. T, Bolysbek A. A, Baiysbay O. P, Abzhanova A. S. Kinetic Studies of Sorption Separation of Phosphorus with Usage of Sorbents on the Basis of Natural Clays. Orient J Chem 2018;34(3). |

| Copy the following to cite this URL: Tleuov A. S, Arystanova S. D, Tleuova S. T, Bolysbek A. A, Baiysbay O. P, Abzhanova A. S. Kinetic Studies of Sorption Separation of Phosphorus with Usage of Sorbents on the Basis of Natural Clays. Orient J Chem 2018;34(3). Available from: http://www.orientjchem.org/?p=45460 |

Introduction

The problem of environment protection is one of the most important problems today [1]. As waste is potential secondary material resources, the operating system of removal of technogenic waste leads to irrevocable loss of valuable secondary material resources, energy and land resources [2]. The production of sorbents [3] and catalysts [4] on the basis of clay raw materials restrains the fact that today influence of modifying on structural, thermal, adsorption and catalytic properties of such materials is insufficiently investigated. The main technogenic waste of phosphoric production are phosphorus sludge which are formed on phosphorus condensation stages [5-11]. In compliances with the modern representations, phosphorus sludge represents phosphorus emulsion in water stabilized with fine-grained solids [12-13].

Considering phosphorus sludge as stabilized with highly active pollution of emulsion in water, the way of phosphorus separation is chosen from sludge with usage of solid porous sorbents on the basis of natural refractory, bentonitic clays and vermiculites [14]. The processing of phosphorus sludge with sorption method provides high extent of phosphorus separation, and usage of native, available natural minerals allows to reach considerable economic and ecological effect for this purpose.

Materials and Methods

The experimental datas were processed with Rotinyan-Drozdov’s equation for definition of chemical process of phosphorus separation from phosphorus sludge with usage of sorbents on the basis of native silica-alumina clays.

![]()

where – M – efficient constant of speed process;

β – drag coefficient

Rotinyan-Drozdov’s equation is used when studying heterogeneous processes and efficient specific reaction rate characterizes the processes beginning on all surface of the heterogeneous system. At the same time finding of drag coefficient defines influence of resultants on the interaction speed process.

Studying of the kinetics of adsorption chemical process was carried out at temperatures of 60, 70, 80, 90°C with isothermal endurance 30, 60, 90, 120, 150 minutes with usage of sorbents on the basis of clays from Kazakhstan’s deposits Darbaza and Lenger and also vermiculite of the Kulandy field which is also located in South Kazakhstan.

Laboratory researches of phosphorus separation from sludge with usage of sorbents on the basis of native clays and vermiculite were carried out on the installation given on the Figure 1.

The work was carried out on the installation which works according to the following scheme. The phosphorus sludge admits from the compressor 1 through a flow meter with the needle nozzle 2. Further it passes through water in the flask 3. The moisture content of air is measured with the sensor of the relative humidity 7. Passing the flask with absorber, cleaned gas with phosphorus is collected in the flask with water 4. Parameters of humidity and air temperature are displayed on digital devices TPM200 (6). The water temperature regulation is carried out in TC4S (9). Maximum withstand water temperature is 90°C.

|

Figure 1: Laboratory installation for adsorption process Click here to View figure |

Results and discussion

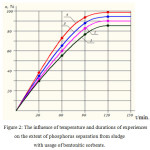

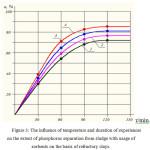

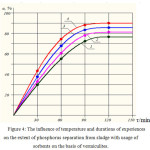

The experimental data of the sorption of phosphorus sludge obtained on the laboratory installation are given in Figures 2-4. Dependences of extent of separation of phosphorus from temperature and time are defined on the residual content of phosphorus in the termination of adsorbed products.

|

Figure 2: The influence of temperature and durations of experiences on the extent of phosphorus separation from sludge with usage of bentonitic sorbents.

|

1 – t =600C; 2 – t =700C; 3 – t =800C; 4 – t =900C;

|

Figure 3: The influence of temperature and duration of experiences on the extent of phosphorus separation from sludge with usage of sorbents on the basis of refractory clays.

|

1 – t =600C; 2 – t =700C; 3 – t =800C; 4 – t =900C;

|

Figure 4: The influence of temperature and durations of experiences on the extent of phosphorus separation from sludge with usage of sorbents on the basis of vermiculites. |

1 – t =600C; 2 – t =700C; 3 – t =800C; 4 – t =900C;

The analysis of graphic data confirms direct dependence of extent of phosphorus separation on the temperature and isothermal endurance of the process. The maximal extent of phosphorus separation up to 98% is reached when using sorbents on the basis of the Darbaza clay modified with sulfuric acid 0,25M.

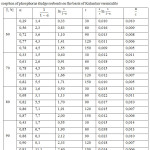

The experimental data of extent dependence of phosphorus separation from phosphorus sludge with various sorbents at the studied temperatures 80-900C and duration 30 -150 minutes, mathematically processed with Rotinyan– Drozdov’s equation are presented in tables 1-3:

|

Table 1: Mathematical processing of experimental data with Rotinyan– Drozdov’s equation of sorption of phosphorus sludge sorbents on the basis of Darbaza bentonitic clay |

|

Table 2: Mathematical processing of experimental data with Rotinyan– Drozdov’s equation of sorption of phosphorus sludge sorbents on the basis of Lenger (refractory) clays |

|

Table 3: Mathematical processing of experimental data with Rotinyan– Drozdov’s equation of sorption of phosphorus sludge sorbents on the basis of Kulantau vermiculite |

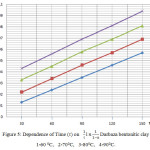

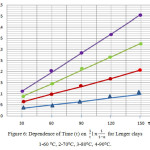

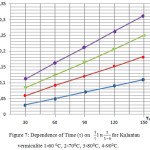

On the basis of mathematical calculation data components of the Rotinyan– Drozdov’s equation are built graphic dependences

![]()

which are presented in figures 5-7.

|

Figure 5 Click here to View figure |

|

Figure 6 Click here to View figure |

|

Figure 7 Click here to View figure |

The analysis of graphic dependences shows that the studied process is described well with Rotinyan–Drozdov’s equation that testifies rectification of the experimental curve dependences of extent of phosphorus separation depending from various factors.

The drag coefficient β1 β2 β3 is calculated on tg φ of each straight line. The efficient specific reaction rate for each temperature was defined from the schedule at

![]()

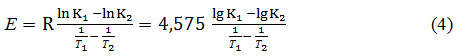

The activation energy defines influence of temperature on the speed process. In practice the calculation “apparent” activation energy for the Arrhenius equation is widespread:

K = Aoe –E/RT (2)

where E – activation energy, kJ/mol.

As concentration of reactants does not depend on the temperature, the same ratio turns out also for the speed process (V).

V = Voe –E/RT (3)

That is the more than E the quicker reaction rate with temperature increasing E is defined from expression:

where 4.575 is the product of conversion factor from natural logarithm into decimal 2.303 and universal gas constant R 1.9865 [kal/Mol∙K]

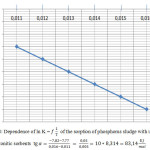

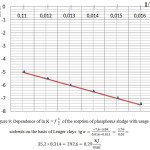

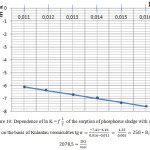

From graphic dependences of ln

![]()

(Fig. 8-10) given for each type of sorbents were calculated values of apparent activation energy (Е app.), which results are given in the table of indexes:

Table 4: Value E each for different types of sorbents

| № | Name of the sorbent | Drag coefficient at T | кJ/mol | |

| 0С | β | |||

| 1 | Darbaza clay | 60 | 0,007 | 83,14 |

| 70 | 0,015 | |||

| 80 | 0,028 | |||

| 90 | 0,039 | |||

| 2 | Kulantau vermiculite | 60 | 0,02 | 2,078 |

| 70 | 0,04 | |||

| 80 | 0,06 | |||

| 90 | 0,08 | |||

| 3 | Lenger clay | 60 | 0,03 | 0,29 |

| 70 | 0,05 | |||

| 80 | 0,07 | |||

| 90 | 0,08 | |||

The graph of dependence of ln

![]()

is presented in Figures 8-10.

|

Figure 8 Click here to View figure |

|

Figure 9 Click here to View figure |

|

Figure 10 Click here to View figure |

Conclusions

The analysis of the obtained values of E app. extents of phosphorus separation from the type of the sorbent show that the maximal extent of phosphorus separation is reached when using sorbents on the basis of Darbaza clay. “Apparent” activation energy has maximal value 83,14 KJ/mol, the drag coefficient β reaches 0,07 – 0,039 that demonstrates course of process of the sorption phosphorus from sludge in transient regime with considerable influence of diffusion factors. The sorption process at using Lenger clay and Kulantau vermiculite is characterized with E app from 0,29 to 2,078 KJ/mol that corresponds about course of process in diffusion area.

Acknowledgments

The work was financially supported by a project GF 68-31 of the Ministry of Education and Science of the Republic of Kazakhstan

References

- Gholipour, H.F., Farzanegan, M.R. Const Polit Econ., 2018, 29: 20-39.

CrossRef - Hoornweg, D., Bhada-Tata, P., Urban Dev Ser Knowl Pap, 2012, 15:1-98.

- Su, Ch., Duan, L., Donat, F., Anthony, E. J., Appl Energy, 2018, 210: 117-126

CrossRef - Soni , V.K., Sharma, P. R., Choudhary, G., Pandey, S., Sharma, R.K. , ACS Sustainable Chem. Eng., 2017, 5 (6), pp 5351–5359

CrossRef - Cordell, D., Rosemarin, A., Schröder, J.J., Smit, A.L., Chemosphere, 2011, 84: 747-758

CrossRef - Donatello, S., Cheeseman C., Waste Manag., 2013, 33:2328-2340

CrossRef - Li, R., Zhao, W., Li, Y., Wang, W., Zhu, X., J. Hazard. Mater., 2015, 283: 423-431

CrossRef - Lapa, N., Barbosa, R., Lopes, M.H., Mendes, B., Abelha, P., Gulyurtlu, I., J. Santos Oliveira, J. Hazard. Mater., 2007, 147(1–2): 175-183

CrossRef - Nakakubo, T., Tokai, A., Ohno, K., J Clean Prod., 2012, 32: 157-172

CrossRef - Garrido-Baserba, M., Molinos-Senante, M., Abelleira-Pereira, J.M., Fdez-Güelfo, L.A., Poch, M., Hernández-Sancho, F., J Clean Prod., 2015, 107: 410-419

CrossRef - Rodríguez, N.H., Martínez-Ramírez, S., Blanco-Varela, M.T., Donatello, S., Guillem, M., Puig, J., Fos, C., Larrotcha, E., Flores, J., J. Clean. Prod., 2003, 52: 94-102

CrossRef - Herzel, H., Krüger, O., Hermann, L., Adam, C., Science of The Total Environment, 2016, 542( B): 1136-1143

- Cieślik, B., Konieczka, P., Journal of Cleaner Production, 2017, 142(4): 1728-1740

CrossRef - Tleuov, A.S., Tleuova, S.T., Altybayev, Zh.M., Suigenbayeva, A.Zh., Orient J Chem, 2016, 32(5): 2577-2584

This work is licensed under a Creative Commons Attribution 4.0 International License.