Silver/oil Nanofluids in Heat Exchanger An Experimental Study on Convective Heat Transfer

Komeil Hosseini and Hamid Reza Ghorbani

Department of Chemical Engineering, Qaemshahr Branch, Islamic Azad university, Qaemshahr, Iran.

Corresponding AuthorE-mail: hamidghorbani6@gmail.com

DOI : http://dx.doi.org/10.13005/ojc/340266

Article Received on : December 06, 2017

Article Accepted on : January 25, 2018

In present work, we used two sizes of silver (Ag) nanoparticles (NPs) with different particle loadings and dispersed them into oil to make nanofluids. The silver/oil nanofluid with different nanoparticles weight fractions of 0.5%, 1% and 2% was prepared by ultrasonic device in two step method. The measurements of heat transfer coefficients were performed. An up to 30% enhancement of the heat transfer coefficient was observed in the laminar flow regime. The heat transfer coefficient is shown to increase with increasing Reynolds number. In addition, the heat transfer coefficient decreased with increasing fluid temperature. A constant downward trend of enhancement ratio with respect to Reynolds number was specified for the nanofluids discussed in this study.

KEYWORDS:Convective heat transfer, Silver/oil nanofluid, Heat exchanger

Download this article as:| Copy the following to cite this article: Hosseini K, Ghorbani H. R. Silver/oil Nanofluids in Heat Exchanger An Experimental Study on Convective Heat Transfer. Orient J Chem 2018;34(2). |

| Copy the following to cite this URL: Hosseini K, Ghorbani H. R. Silver/oil Nanofluids in Heat Exchanger An Experimental Study on Convective Heat Transfer. Orient J Chem 2018;34(2). Available from: http://www.orientjchem.org/?p=44481 |

Introduction

Nanotechnology includes the integration of smaller structures into larger materials, keeping the construction of new material at nano-scale. Nanoparticles are also present in different morphologies such as rods, spheres, prisms and tubes1. Nanoparticles made of zinc, iron, titanium, alginate, copper, gold and silver are known to exhibit antimicrobial properties2. Nanoparticles due to their smaller size offer advantage by improving biocompatibility. It seems that bacteria are less likely to develop resistance against nanoparticles because nanoparticles have broad spectrum antibacterial activity and for bacteria to get resistant many mutations must occur. In spite of modern technologies like UV -radiation, laser ablation, photochemical reduction and lithography technologies have been successfully used; to produce nanoparticles, their greater cost and use of harmful chemicals marks their limitations3-5. The field of nanotechnology is one of the most active area of research which suddenly bring through among all sciences. Then field of nanoparticles exhibits completely a new and improved properties based which comes with totally new characteristics such as morphology and distribution and size6. There are two factors causes the property of nanomaterial significantly differ drastically from other materials which is increase surface area and quantum confinement effect such as reactivity, strength, electrical conductivity etc.6-7. For synthesis of Ag NPs, a number of synthesis approaches are available for example photochemical and chemical reactions, thermal decomposition, reduction in solution, electrochemical, sonochemical, microwave and also green synthesis8. Nanofluids are a suspension from nanoparticles smaller than 100 nm in size that dispersed in a base fluid9. They are a category of new heat transfer fluids that used in conventional heat transfer fluids. It is used usually two-step method to prepare them9.

Nanofluids are nanoparticles suspensions containing metal and non-metallic materials. Because of nanoscale particles in base fluids, it was created a new generation of fluids with a huge potential in the industry6. The size of used nanopartcles in nanofluids is from 1 nm to 100 nm and consists of metals such as copper and silver or metal oxide such as aluminum oxide and copper oxide. In industry, there is problems such as sedimentation, sedimentation particles, rubbing, blocking the tubes, increased pressure drop in the fluid duct, causing researchers to bring nanofluids, which was a great revolution in heat transfer3. The problems caused by scratching, impurities and pressure drop decreased due to the small amount of particles in nanofluid. In addition, the nanofluid stability increased compare with adding micro particles to base fluid significantly10.

One of the basic needs for many industries is a high-efficiency heat transfer fluid. Cooling and heating fluids are important for industrial processes that include heat sources, manufacturing processes, transport and electronics5. Heat transfer environments contains fluids such as water, ethylene, glycol and oil. These fluids have a low heat transfer coefficient in comparison to metals and even metal oxides, so fluids containing nanoparticles of these compounds exhibit better properties. Nanofluids can be considered as one of the most suitable and most effective choice for heat transfer. Small particles in the nanofluids reduce the corrosion, pressure drop and make the fluid more stable9. Today research on nanofluids has become widespread. Researchs indicate that the use of nanoparticles in the base fluid increase the heat and mass transfer coefficients. Increasing the h and k coefficients increase the efficiency, reduce the size of the equipment, as well as the cost of making them11.

In present work, it was used 3 sizes of Ag NPs. with various concentrations and dispersed them into oil to make nanofluids. The h coefficients were calculated. Three different weight fractions of nanofluids (0.5, 1 and 2%) were prepared by dispersing silver nanoparticles in oil. The properties of nanofluids were measured at 5ºC, 25ºC and 100ºC and also, the different sizes of nanoparticles were dispersed in oil (10-20 and 90-100 nm).

Experimental

Powder of silver nanoparticles was purchased from Sigma-Aldrich (Germany). The silver/oil nanofluids with different volume concentrations were prepared by dispersing silver nanoparticles with sizes of 10-20 nm and 90-100 nm into oil. In present study, three different volume concentrations of nanofluids (0.5, 1 and 2%) were prepared by dispersing silver nanoparticles in oil. Also, convective heat transfer coefficients were measured at 5ºC, 25ºC and 100ºC. The h can be calculated by 12:

The h was computed by the following equation12:

The Reynolds number (Re) is calculated using the averaged properties12:

Results and Discussion

Temperature Effects on Convective Heat Transfer Coefficient

Water bath was used to control fluid temperature in the heat transfer apparatus. It was used three temperatures (5°C, 25°C, and 100°C) to measure of the h. The heat transfer enhancement reduces with increasing fluid temperature at the similar flow rate for silver nanofluids4. The relation of h to the h0 is expressed as the increase of h (Fig. 1).

|

Figure 1: The h/h0 of Ag NPs on Re in different temperatures |

Effect of Nanoparticle Size of Nanofluids on h

The effect of nanoparticles size was investigated by drawing the increase ratio h under similar conditions versus Re. Consequences are shown in Fig. 2 for nanofluids at 25°C. The average increase h for Ag 10-20 nm nanoparticles of nanofluid was about 11.1%. For Ag 90-100 nm nanofluids, the enhancement was 7.1%. It was observed similar results for other temperatures. It obtained similar results with previous researches5,9.

|

Figure 2: Effect of silver nanoparticle size of nanofluids on enhancement of heat transfer coefficient |

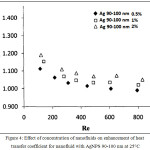

Effect of Concentration of Nanofluids on h

A synopsis of consequences for the effect of nanoparticles concentration are showed in Figures 3 and 4 at 25°C. The increase of heat transfer coefficient was showed for 3 concentrations of Ag 10-20 nm and Ag 90-100 nm nanofluids. The maximum increase of h for nanofluid with AgNPS 10-20 nm was about 11.5 %, 12.1% and 12.4% for concentrations of 0.5%, 1% and 2% at Re around 100 respectively. For nanofluid with Nano-Ag 90-100 nm, the maximum enhancement h for nanofluid was at Reynolds number around 100 but with 0.5% lower. For two different concentrations of nanofluids showed a same rise performance for Re more than 200. In addition, enhancement h increased with increasing concentration of nanofluid. It was observed similar results for other temperatures. It obtained similar results with previous researches3,12.

|

Figure 3: Effect of concentration of nanofluids on enhancement of heat transfer coefficient for nanofluid with AgNPS 10-20 nm at 25°C Click here to View figure |

|

Figure 4: Effect of concentration of nanofluids on enhancement of heat transfer coefficient for nanofluid with AgNPS 90-100 nm at 25°C Click here to View figure |

Conclusion

This paper exhibited the development of investigation on the improvement h using nanofluids. In this work, two different sizes (10-20 nm and 90-100 nm) of silver nanoparticles were used to dispersed into oil using a sonic dismembrator. Results presented heat transfer coefficients of base and nanofluids enhance with raising flow rate and Re. The heat transfer coefficient reduces with raising the fluid temperature. Nanofluids h is the more than base fluids h for all nanofluids. The best enhancement was demonstrated in nanofluids with the smallest nanoparticles size (10-20 nm).

Acknowledgement

The authors thank the Pars Potas Company for its financial support to the present research project.

References

- Yu, W.; Choi, S. J. Nanopart. Res 2003, 5, 167-171.

CrossRef - Abu-Nada, E.; Chamkha, A.J. Int. J. Therm. Sci. 2010, 49, 2339-2343.

CrossRef - Salehi, J. M.; Heyhat, M. M.; Rajabpour. A. Appl. Phys. Lett. 2013,102, 231907.

CrossRef - Xuan, Y.; Roetzel, W. Int. J. Heat Mass Trans. 2000, 43, 3701–3707.

CrossRef - Chein, R.; Chuang, J. Int. J. Therm. Sci. 2007, 46, 57-61.

CrossRef - Ma, Q.; Fang, H. ASME. 2016, 7, 11–17.

- Duangthongsuk, W.; Wongwises, S. Int. Commun. Heat Mass Trans. 2008, 35, 1320-1325.

CrossRef - Hwang, K.S.; Jang, S.P.; Choi, S. Int. J. Heat Mass Trans. 2009, 52, 193–199.

CrossRef - Li, Q.; Xuan, Y. Sci. China 2002, 45, 408-413.

CrossRef - Xuan, Y.; Li, Q. ASME J. Heat Trans. 2003, 125, 151-156.

CrossRef - Mirmasoumi, S.; Behzadmehr, A. Int. J. Heat Fluid Flow 2008, 29, 557–66.

CrossRef - Hayat, T.; Nadeem, S. Results Phys. 2017, 7, 2317-2324.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.