Testing new surfactant formulations on stable 20-80% water-in-diesel emulsion fuel production (one week stability)

Souleyman A. Issaka, Abdurahman H. Nour, and Rosli M. Yunus

Faculty of Chemical and Natural Resources Engineering University Malaysia Pahang 12, 25000, Kuantan, Pahang, Malaysia. Correspondence Author Email: salimbiltine@yahoo.com

DOI : http://dx.doi.org/10.13005/ojc/310352

Article Received on :

Article Accepted on :

Article Published : 19 Aug 2015

The current research is aimed to introduces new formulations of additives to stabilise 20% water mixed emulsion fuel made of commercial diesel and water. various formulations of emulsifiers were prepared in a lab scale and their efficiency were tested in water-in-diesel (w/d) emulsions, the formulated emulsifiers were designated as sample A (SA), sample B(SB), sample C (SC) and sample D (SD) sample E (SE) and sample F (SF). Stabilty study was conducted by obseving (visually) and recording the changes as well as phases separation. Stbility assessment was conducted in two stages, in the first stage, the amount of water or oil separation from the freshly prepared emulsion were recorded for an hour at 10 minutes interval, if there is any water or oil separation within this 10 minutes then emulsion is considered unstable or failed to pass to the second stage. In the second stage, water separation and pictures for visual obsevation were taken in a daily basis for one week. The optimal and most stable emulsion fuels were observed with samples C, D and F, which gave zero separation of phaces within one week. Followed by samples B and E whom each gave 3.8% oil separation, then sample A which gave 5% water separation. Based on this results, authors have no single doubt to say that, the new formulation C,D and F surfactant are very effective stabilizers for emulsion fuel and performed far better than their commercial counterpart.

KEYWORDS:Emulsion fuel stabilizer; diesel emulsion; water-in-diesel emulsions; low emission fuel formula

Download this article as:| Copy the following to cite this article: Issaka S. A, Nour A. H, Yunus R. M. High Testing new surfactant formulations on stable 20-80% water-in-diesel emulsion fuel production (one week stability). Orient J Chem 2015;31(3). |

| Copy the following to cite this URL: Issaka S. A, Nour A. H, Yunus R. M. High Testing new surfactant formulations on stable 20-80% water-in-diesel emulsion fuel production (one week stability). Orient J Chem 2015;31(3). Available from: http://www.orientjchem.org/?p=10272 |

Introduction

The trend toward low emmission fuels is increasing world wide.The current research relates to producing stable 20% water mixed diesel fuel. this is because the existance of water in the diesel fuel is proved to significantly reduce the emmission of toxic gases. Nitrous oxide is a renown active irritant in smog and expected to participate to the tropospheric ozone, this of course a clear threat in terms of health and environmental consideration, thus, policy maker and legal bodies have increasingly earged the reduction of nitrous oxide emmission which caused mainly from diesel fueled machineries. Mixing water with the fuel also proved to reduce the high flame temperature reached during fuel combustion particularely in diesel based internal combustion engines and that eventually leads to abatement in nitrous oxide formation [1].

The fundamental method of producing the fuel emulsion is first bringing the different components (diesel, water, and surfactants) together in a vessel and mixing them up vigourously to provide the shear necessary to produce desired droplet sizes [2].

Ton thi and colleagues have synthesised polyethylene ester based nonionic surfactants which were catalysed with Acid catalyst under vaccum pressure at temperature of 130 ⁰C. The noticed that using excess fatty acid would leads to the formation of diester which perform better in w/o systems. Others parameters such as reaction time, and catalyst concentration were also investigated [3]. A. K. Hasanuddin and coleagues investigated the essential variables for synthesing stable emulsion fuel which comprise of type of surfactants, propeller speed ( mixing speed), and mixing time, they found that stability was a strong function of types of surfactant [2]. Other group of researchers have addressed several issues pertaining to the formation as well as utilization of water-in-diesel emulsion fuel. Thus, they have formulated nanoemulsion by adding different concentration of water in the diesel fuel, various surfactants as well as combustion improving nano additives were tested [4].

This study is aimed to investigate the effects of surfactant formulation on the stability of 20-80% water-in-diesel (W-in-D) emulsion fuel. Six different formulsions (SA, SB, SC, SD, SE, SF) were studied, S’s are stand for sample (e.g sample A (SA) and etc.).

Methodology

Samples of 20-80% water-in-diesel (w-in-D) emulsions were prepared with various types of locally formulated surfactants. emulsions were mixed vigorousely using three blade propeller at 1800 rpm for eight minutes. Stabilty study was conducted by obseving and recording the changes and phses separation. Stbility assessment was conducted in two stages, in the first stage, the amount of water separation from the freshly prepared emulsion were recorded for an hour at 10 minutes interval, if there is any water or oil separation within this 10 minutes then emulsion is considered unstable or failed to pass to the second stage. In the second stage, water separation and pictures for visual obsevation were taken in a daily basis for one week.

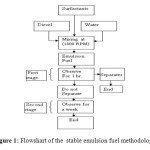

The procedures are illustrated in figure 1.

|

Figure 1: Flowshart of the stable emulsion fuel methodology Click here to View figure |

Results and Discussions

The experimental results of this research shall be presented in this part, parameters of interest are the emulsion splitting (either oil or water separation) and pictures of visual observation to observe the change in the color. Six formulations were studied namely sample (A,B,C,D,E,F).

Table 1: Separation efficiencies for samples (A and B)

| Time (min.) | Separation Sample A (ml) | Separation Sample B (ml) | ||

|

First Stage |

||||

| oil | water | oil | water | |

| 10 | 3 | 0 | 0 | 1 |

| 20 | 3 | 0 | 0 | 1 |

| 30 | 3 | 0 | 0 | 1 |

| 40 | 3 | 0 | 0 | 1 |

| 50 | 3 | 0 | 0 | 1 |

| 60 | 3 | 0 | 0 | 1 |

| Time (days) |

Second stage |

|||

| 1 | 3 | 0 | 0 | 1 |

| 2 | 3 | 0 | 0 | 1 |

| 3 | 3 | 0 | 0 | 1 |

| 4 | 3 | 0 | 0 | 1 |

| 5 | 3 | 0 | 0 | 1 |

| 6 | 3 | 0 | 0 | 1 |

| 7 | 3 | 0 | 0 | 1 |

Table 1 represents the rawn data collected from the stability study, data were collected each 10 minutes interval for frshely prepared emulsion in their first one hour (first stage). After that data were taken in an daily basis for seven days (second stage). Basically there were no water separation at all for both samples, however, little oil separation of 3 ml (15%) was recorded for sample A, snd litle water separation of 1ml (5%) were observed This means both samples (A and B) can produce stable diesel emulsion fuel with 20% water content. For more clarification, sellected pictures of the samples shall be shown next.

|

Figure 2: Sellected pictures of sample A at different days (0,1,5,7) |

|

Figure 3: Sellected pictures of sample B at different days (1,3,5,7) |

Figures 2 and 3 show some sellected pictures of samples (A and B) with time, each picture is taken individually in different days as writen in the pictures themselves, fore instance, the number one (1) on the measuring cylinder on figures 2 and 3 means the picture was taken after one day, same goes to the others (3 was captured three days from the day its prepared and so on).

Visual obsevation also showed that emulsions from both formulations were stables and any change in their color with time.similar results were observed by M.T. Gnannam and colleague who produced stable 20-80% water-in-diesel emulsion that was stable for 10 days, then only water started to resolve. However, they did not mentioned the oil separation in their report. They used 0.2% emulsifying agent (iso-octylphenoxypolyethoxyethanol). The mixing speed and time were 15,000 revolution per minutes (RPM) and 2 minutes respectively [5].

Table 2: Separation efficiencies for samples (C and D)

| Time (min.) | Separation Sample C (ml) | Separation Sample D (ml) | ||

|

First Stage |

||||

| oil | water | oil | water | |

| 10 | 3 | 0 | 0 | 0 |

| 20 | 3 | 0 | 0 | 0 |

| 30 | 3 | 0 | 0 | 0 |

| 40 | 3 | 0 | 0 | 0 |

| 50 | 3 | 0 | 0 | 0 |

| 60 | 3 | 0 | 0 | 0 |

| Time (days) |

Second stage |

|||

| 1 | 3 | 0 | 0 | 0 |

| 2 | 3 | 0 | 0 | 0 |

| 3 | 3 | 0 | 0 | 0 |

| 4 | 3 | 0 | 0 | 0 |

| 5 | 3 | 0 | 0 | 0 |

| 6 | 3 | 0 | 0 | 0 |

| 7 | 3 | 0 | 0 | 0 |

Table 2 represents the experimental results of stabilty test for emulsion fuel samples prepared from samples (C and D) surfactant formulsions. As shown on the table all recorded results were zeros, which means there were no any of either water or oil separations for a period of one week (7 days), a picture of the emulsions being studies would is shwn next for more clarifications and visual observation. Omar badaran and colleagues have studied the stability and rheological properties of emulsion fuel produced by using 4% of commercial surfactants [6].

|

Figure 4: Sellected pictures of sample C at different days (0,2,5,7) |

|

Figure 5 : Sellected pictures of sample D at different days (0,2,5,7) Click here to View figure |

Figure 4 and 5 show pictures of emulsion fule samples prepared from surfactants formulation denoted as sample C and D respectively. The numbers on the samples (0,2,5,7) denote the days on which the every picture was taken. It is clear that emulsions prepared from formulations (C and D) were very satable based on phase sepation as well as visual observations. Phase sepation was conducted for seven days (one week) and there were no water or oil separation within that period, results are shown in tables 2. Visual observation also proved that the color dose changes with time for this period of one week (figures 4 and 5).

Table 3: Separation efficiencies for samples (E and F)

| Time (min.) | Separation Sample E (ml) | Separation Sample F (ml) | ||

|

First Stage |

||||

| oil | water | oil | water | |

| 10 | 3 | 0 | 0 | 0 |

| 20 | 3 | 0 | 0 | 0 |

| 30 | 3 | 0 | 0 | 0 |

| 40 | 3 | 0 | 0 | 0 |

| 50 | 3 | 0 | 0 | 0 |

| 60 | 3 | 0 | 0 | 0 |

| Time (days) |

Second stage |

|||

| 1 | 3 | 0 | 0 | 0 |

| 2 | 3 | 0 | 0 | 0 |

| 3 | 3 | 0 | 0 | 0 |

| 4 | 3 | 0 | 0 | 0 |

| 5 | 3 | 0 | 0 | 0 |

| 6 | 3 | 0 | 0 | 0 |

| 7 | 3 | 0 | 0 | 0 |

Table 3 represents the experimental results stability test obtained from emulsions prepared from surfactant formulations of sample E and F. Again no separations were observed on samples prepared from samples E and F surfactant formulations, which means samples E and F produces are good formulations for producing stable emulsion fuel.

|

Figure 6: Sellected pictures of sample E at different days (0,2,5,7) |

|

Figure 7: Sellected pictures of sample F at different days (0,2,5,7) |

Figures 6 and 7 shows some sellected pictures of emulsion fuels stabilised with formulations Sample E and F respectively. Pictures were taken in a daily bases every 24 hours for one week (7 days). It is found that there was no visual change on the sample with time for this specific period of time which means samples prepared with sample E and F stabilisers are very stables. In previous article, stable emulsion fuel was produced via mixind 10% warm water plus additives. Mixture consisting of sodium hydroxide, calcium hydroxide and chlorine [7]. Another researcher investigated the critical parameters that goven the formulation emulsion fuel and their possible environmental impacts [8]. Pradeep kumar and colleagues had successfully tested their stable emulsion fuel consisting of 5,10 and 15% emulsified water on a single cylinder direct injection diesel engine, the diesel-water emulsion fuel was stablised by using 1% mixture of span 80 and tween 80 surfactants [9].

Conclusion

The performance and stability pattern of new emulsifiers were tested on emulsion fuel sample. Various numbers of surfactants and six different formulations (sample (A-F)) were tested in preparing stable water-in-diesel fuel emulsions, stability assessment was performed by observing visually and reading the amount of water or oil separated from the emulsions within one week. Results showed that, for sample A, there was 3ml (3.8%) of separated oil and no water separation within one week of observation. for sample B, there was no oil separation but there was 1ml (5%) of water separation. For sample E, there were 3ml (3.8%) separated oil but there was no water separation. While for samples C,D and F there were no either water or separation and no changes in visual observation either within one week of observation period.

Reference

- Gerald N.coleman, stable fuel emulsions and method of making, US Patent:6,607,566B.

- A.K. hasannuddin, M.I. Ahmad, M.Zahari and J.Y.Wira, Stability studies of water-in-diesel emulsion, J. of applied mechanics and materials 2014;663:54-57.

- Tong thi et al., synthesis of non-ionic-polyethyleneglycole ester based surfactants for water-in-oil emulsions, AUN/SEED-Net first regional global environmental conferance

- Rakhi N. Mehta, Utkarsh More, Naved Malek, Mousumi Chakraborty, Parimal A. Parikh, Study of stability and thermodynamic properties of water-in-diesel nanoemulsion fuels with nano-Al additive, Journal of applied nanoscience (2015); DOI:10.1007/s13204-014-0385-3

- M.T.Ghannam and M.Y.E.selim, Stability behavior of water-in-diesel fuel emulsion, J. of petroleum science and technology (2009)

- Omar badran, sadeq emeish, mahmoud abu-zaid, tayseer abu-rahma, mohammad al-hassan, mumin al-ragheb, impact of emulsified water diesel mixture on engine performence and environment, International journal of thermal and environmental engineering 2011;3:1-7.

- Agung sudrajad, fujita hirotsugu, ismail ali, experimental study of exhaust emission of w/o emulsion fuel in DI single cylinder diesel engine, journal of applied science 2011; 5: 73-79.

- A.N. Dipofori-orji., critical process involved in formulation of water-in-fuel oil emulsions, conbustion efficiency of the emulsified fuel and their possible environmental impact, research journal of applied science, engineering and technology 2011;3:701-706.

- Pradeep Kumar AR,Annamalai K, premkartikkumar SR, senthur NS, effect of emulsified fuel on performance and characteristics in diesel engine, Journal of chemical and pharmaceutical sciences, ISSN:0974-2115.

This work is licensed under a Creative Commons Attribution 4.0 International License.