An Efficient an One-Pot Method for Synthesis of 2-Aryl-(3H)-4-Quinazolinones Derivatives Catalyzed by SSA

Farhad Hatamjafari *, Sima Eslami

Department of Chemistry, Faculty of Science, Islamic Azad University-Tonekabon Branch, Tonekabon, Iran

DOI : http://dx.doi.org/10.13005/ojc/300259

Article Received on :

Article Accepted on :

Article Published : 11 Apr 2014

A mixture of 2-amino benzamide with aromatic aldehyds in the presence of SSA under solvent-free condition were converted to quinazolinones with good yields.

KEYWORDS:Starch SulphuricAcid (SSA); (3H)-4-Quinazolinones; One-pot; Solvent-Free

Download this article as:| Copy the following to cite this article: Hatamjafari F, Eslami S. An Efficient an One-Pot Method for Synthesis of 2-Aryl-(3H)-4-Quinazolinones Derivatives Catalyzed by SSA. Orient J Chem 2014;30(2). |

| Copy the following to cite this URL: Hatamjafari F, Eslami S. An Efficient an One-Pot Method for Synthesis of 2-Aryl-(3H)-4-Quinazolinones Derivatives Catalyzed by SSA. Orient J Chem 2014;30(2). Available from: http://www.orientjchem.org/?p=2904 |

Introduction

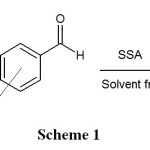

Natural compounds with quinazolinestructural motif have been identified to display a wide range of biological activities. The prominent potencies associated with quinazoline containing compounds are their anticancer,anti-inflammatory, anthelmintic, analgesic, and anticonvulsive activities1-5.we now report that cyclocondensation of 2-aminobenzamides (1) with aromatic aldehyds(2) on silica-supported sulfuric acid quickly provides the substituted quinazolin-4(3H)-ones (3) in fairly high yields. To our knowledge there has been reported on the use of sulfuric acid adsorbed on silica gel (SiO2/H2SO4)as a solid catalyst in the synthesis of quinazolines.Various catalysts were used in the synthesis of quinazolinone derivatives6-14. The early method, based on the reaction of 2-aminobenzamide with aldehyds, was performed in the presence of H2SO4 and as a requirement of its refluxing condition much excess of aldehyds was used15.Though an excess of aldehyds is necessary to diminish the intermolecular side-reactions, the conventional beating method ever needs additional aldehyds both to improve the yield. In contrast to the Liquid H2SO4, which is difficult to recovery and takes some effort in work-up, the silica-supported H2SO4, can be easily separated and recycled without the loss of activity for several times. Thus, 2-aminobenzamides (1) reacted with nearly 2 equivalents of aromatic aldehyds(2) with the aide of SiO2/H2SO4 and submission to microwave irradiation to provide fairly high yields of substituted quinazolin-4(3H)-ones (2a-d) in 25 minutes.However, these reactions often require harsh conditions and long reaction time and low efficiency can. Aromatic aldehydes, especially wheused to replace for synthesis quinazolinones. Previously, we have synthesized a number of heterocyclic compounds16-28. Herein we report some of quinazolinones at one pot reaction, environmentally friendly with high yields and easy separation (Scheme 1).

|

Scheme 1: Click here to View Scheme |

(3-nitrophenyl)-(3H)-4-Quinazolinone (2a-d)

Pale Blue crystals, Yield: 87%, m.p> 300 °C, FT-IR (Vmax/cm-1) (KBr disc): 3440(amid NH Str.); 3092(arom CH Str.); 1682(amid C=O Str.); 1640(C=N Str.); 1520, 1360(N-O Str.).1H NMR(400.13MHz, DMSO): δ= 7.56 (1H, t, 3J= 8Hz, 1CH); 7.79-7.88 (3H, m, 3CH); 8.17(1H, d, 3J = 8Hz, 1CH); 8.42(1H, d, 3J = 8Hz, 1CH); 8.61(1H, d, 3J = 8Hz, 1CH); 9.02(1H, s, 1CH); 11.82 (1H, s, NH).

(4-methoxyphenyl)-(3H)-4-Quinazolinone (2b)

Yellow crystals, Yield: %72, m.p= 245-248 °C, FT-IR (Vmax/cm-1) (KBr disc): 3410 (amid NH Str.); 3131(arom. CH Str.); 2990(aliph. CH Str.); 1675(amid C=O Str.); 1643(C=N Str.).

(4-chlorophenyl)-(3H)-4-Quinazolinone (2c)

White crystals, Yield: 89%, m.p = 302-304 °C, FT-IR (Vmax/cm-1) (KBr disc): 3410 (amid .NH str.); 3078 (arom. CH str.); 1670(amid. C=O Str.); 1648(C=N Str.).1H NMR ( 400.13 MHz, DMSO): δ=7.53(1H, t, 3J =7.8, 1CH); 7.63(2H, d, 3J =7.8, 2CH); 7.75(1H, d,3J=7.8 1CH); 7.84(1H, t, 3J =7.8, 1CH); 8.16(1H, d, 3J =7.8, 1CH); 8.21(2H, d, 3J =7.8, 2CH); 11.54(1H, s, NH).

(4-nitrophenyl)-(3H)-4-Quinazolinone (2d)

Pale yellow crystals, Yield: 69%, m.p=361-363°C,FT-IR (Vmax/cm-1) (KBr disc): 3380(amid. NH Str.); 3050(arom. CH Str); 1678(amid. C=O Str.); 1635(C=N Str.); 1530, 1355(N-O Str.).H NMR ( 400.13 MHz, DMSO): δ =7.56(1H, t, 3J= 7.2, 1CH); 7.78(1H, d, 3J = 7.2, 1CH); 7.86(1H, t, 3J = 7.2, 1CH); 8.17(1H, d, 3J = 7.2, CH); 8.37-8.42(4H, dd, 3J = 8.8, CH); 11.41(1H, s, NH).

General Procedure for the Preparation of (3H)-4-Quinazolinone Derivative

In conclusion, in comparison with the precedent related methods which show drawbacks from the standpoints of, prolong refluxing in solvent, need to inert gas, and consuming more aldehyds, the notable advantages of this methodology are: mild conditions in a solvent-free system, fairly high yields, fast reaction, no aqueous work-up and safe and environmental friendly conditions.

References

- Gellibert F., Fouchet M. H., Nguyen V. L., Wang R., Krysa G., de Gouville A. C., Huet S. and Dodic N. Bioorg. Med. Chem. Lett., 19: 2277 (2009).

- Khan M. T. H., Khan R., Wuxiuer Y., Arfan M., Ahmed M. and Sylte I. Bioorg. Med. Chem., 18: 4317 (2010).

- Azizian J., Shameli A., Balalaie S., Ghanbari M. M., Zomorodbakhsh S., Entezari M., Bagheri S. and Fakhrpour G. Orient. J. Chem., 28: 327 (2012).

- Mulakayala N., Kandagatla B., Ismail Rapolu R. K., Rao P., Mulakayala C., Kumar C. S., Iqbal J. and Oruganti S. Bioorg. Med. Chem. Lett., 22: 5063 (2012).

- Adib M., Ansari S., Mohammadi A. and Bijanzadeh H. R. Tetrahedron Lett., 51: 30 (2010).

- Zhou J. and Fang J. J. Org. Chem., 76: 7730 (2011).

- Roopan S. M., Maiyalagan T. and Khan F. N. Can. J. Chem., 86: 1019 (2008).

- Tavakoli-Hoseini N. and Davoodnia A. Chin. J. Chem., 29: 1685 (2011).

- Wang X-S., Yang K., Zhang M-M. and Yao C-S. Synth. Commun., 40: 2633 (2010).

- Chen J., Wu D., He F., Liu M., Wu H., Ding J. and Su W. Tetrahedron Lett., 49: 3814 (2008).

- Tavakoli-Hoseini N. and Davoodnia A. Synth. React. Inorg. Met. Org. Chem., 42: 76 (2012).

- MohammadiZiarani G., Lashgari N. and Badiei A. Sci. Iran., 20: 580 (2013).

- MohammadiZiarani G., Badiei A., Mousavi M., Lashgari N. and Shahbazi A. Chin. J. Catal., 33:1832 (2012).

- MohammadiZiarani G., Badiei A., Dashtianeh Z., Gholamzadeh P. and HosseiniMohtasham N. Res. Chem. Intermed., 39: 3157 (2013).

- Mckee M K., Mckee R L. and Bost R W. J. Am. Chem. Soc., 69: 184 (1947).

- Azizian J., Hatamjafari F., Karimi A. R. and Shaabanzadeh M., Synthesis, 5: 765 (2006)

- Azizian J., Shaabanzadeh M., Hatamjafari F. and Mohammadizadeh M.R., Arkivoc, (xi): 47 (2006).

- Hatamjafari F., Synthetic Communications, 36: 3563 (2006).

- Azizian J., Hatamjafari F. and Karimi A. R., Journal of Heterocyclic Chemistry, 43:1349 (2006).

- Hatamjafari F and Montazeri N., Turkish Journal of Chemistry,33: 797 (2009).

- Bidram A., Hatamjafari F and Doryeh A., Orient. J. Chem., 29: 123 (2013).

- Hatamjafari F., Orient. J. Chem., 28: 141 (2012).

- Hatamjafari F., Orient. J. Chem., 29: 93(2013).

- Hatamjafari F and Alijanichakoli F., Orient. J.Chem.,29: 145(2013).

- Hatamjafari F and Hosseinian A., Orient. J.Chem.,29: 109(2013).

- Hatamjafari F and Keyhani A., Orient. J.Chem.,29: 783 (2013).

- Hatamjafari F and Khojastehkouhi H., Orient. J. Chem., 30(1) (2014).

- Hatamjafari F and GermaniNezhad F., Orient. J. Chem., 30(1) (2014).

This work is licensed under a Creative Commons Attribution 4.0 International License.