NaBH4/C: A Convenient System for Reductive Amination of Aldehydes

Sajjad Taie Hasanloie and Davood Setamdideh*

Department of Chemistry, College of Sciences, Mahabad Branch, Islamic Azad University, Mahabad, Iran.

DOI : http://dx.doi.org/10.13005/ojc/300145

Article Received on :

Article Accepted on :

Article Published : 05 Mar 2014

In this context, NaBH4 in the presence of activated charcoal has been used for thereductive aminationofa varietyof aldehydes withanilines. The reductive amination reactions have been performed within 60-100 min in THFunder reflux conditionsin high to excellent yields of products (85-90%).

KEYWORDS:NaBH4; Charcoal; Reductive amination; Aldehydes; Amines

Download this article as:| Copy the following to cite this article: Hasanloie S. T, Setamdideh D. NaBH4/C: A Convenient System for Reductive Amination of Aldehydes. Orient J Chem 2014;30(1) |

| Copy the following to cite this URL: Hasanloie S. T, Setamdideh D. NaBH4/C: A Convenient System for Reductive Amination of Aldehydes. Orient J Chem 2014;30(1). Available from: http://www.orientjchem.org/?p=2314 |

Introduction

The reductive aminationreaction is a suitable procedure for the preparation of amines from their corresponding of aldehydes. Because, other approaches such as: the reduction of nitro, cyano, azide, carboxamide compounds or the alkylation of amines are often problemssuch as: harsh reaction conditions, overalkylation, low chemical selectivity and generally poor yields. The reductive aminationreactionhas been carried out by sodium borohydridewith different reducing system1-15.But, in continuing our efforts for the development of new reducing systems 16-28,in this context, we have reported the reductive amination reaction of aldehydes with anilines by NaBH4/C system in THF.

Results and Discussions

In the past, we have distributed some application of activated charcoal as catalyst in different reducing system such as: NaBH4/C for the reduction of carbonyl compounds27and the reduction of nitro arenes28.Recently, we have reported Zn(BH4)2/C is an efficient reducing system for the reduction

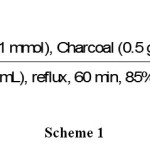

of carbonyl compounds20. Here in, we have used NaBH4/C as convenient system for reductive amination of aldehydes with anilines. For this goal, the model reaction has been performed by reductive amination of benzaldehydeand aniline. This reaction was carried outwith different molar ratio of the benzaldehyde/aniline/charcoal/NaBH4in different solvents for the optimazition reaction conditions. Our experiments have been shown that using 0.5 gof activated charcoalin THF (5 mL) under reflux conditions is the best conditions to complete the reductive amination of benzaldehye (1 mmol) and aniline (1 mmol) to N-benzylaniline. The reductive aminationwas completed within 60 min with 85% yields of product as shown in

scheme 1.

|

Scheme : 1 |

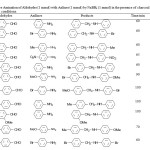

The various structurally different aldehydes and anilines have been used by this reducing system.Experiments have been shown the correspondingsecondary amines were obtained in excellent yields (85-90%) within 60-100 min(Table 1); therefore the efficiency of this protocol was further examined for the reductive amination of aldehydes. The influence of activated charcoal is not clear but we have reported 26-27 sodium borohydride is slowly decomposed by activated charcoal. Consequently, it is liberated hydrogen gas in situ. Thus, the generated molecular hydrogen accelerate the reduction reaction.

|

Table 1. Reductive Amination of Aldehydes (1 mmol) with Anlines (1 mmol) by NaBH4 (1 mmol) in the presence of charcoal (0.5 g) in THF (5 mL) under reflux conditions. Click here to View table |

Experimental

The products were characterized by their 1H NMR (400 MHzBruker)or IR (PerkinElmer FT-IR RXI) and comparison with authentic samples (melting or boiling points). TLC was applied for the purity determination of substrates, products and reaction monitoring over silica gel 60 F254 aluminum sheet.

Reductive amination of banzaldehyde and aniline with NaBH4/Charcoal system (typical procedure)

In a round-bottomed flask (10 mL) equipped with a magnetic stirrer, a solution of benzaldehyde (0.106 g, 1 mmol), aniline (0.093 g, 1 mmol) and activated charcoal(0.5 g) was preparedin THF (5 mL). Then the NaBH4 (0.036 g, 1 mmol) was added to the reaction mixture and stirred under reflux conditions. TLC monitored the progress of the reaction (eluent; CCl4/Ether: 5/2). The reaction was filtered after completion within 60 min. Evaporation of the solvent and short column chromatography of the resulting crude material over silica gel (eluent; CCl4/Ether: 5/2) afforded the N-benzylaniline (0.l53 g, 85% yield, Table 1, entry 1).

Conclusion

In this research, we have shown that the NaBH4/charcoalis convenient system for the reductive amination of a variety of aldehydes and anilines to their corresponding secondary amines. The reduction reactions were accomplished with NaBH4 (1 mmol) and activated charcoal (0.5 g) in THFunder reflux conditions.High efficiency of the reduction reactions and easy work-up procedure makes as an attractive new protocol for reductive amination of aldehydes.

Acknowledgements

The authors gratefully appreciated the financial support of this work by the research council of Islamic Azad University branch of Mahabad.

References

- Alinezhad, H.;Tollabian, Z.Bull. Korean Chem. Soc., 81: 1927( 2010).

- Alinezhad, H.;Tajbakhsh, M.;Mahdavi, N.Synth. Commun.,40: 951( 2010).

- Alinezhad, H.;Tajbakhsh, M.;Hamidi, N.Turk. J. Chem.,34: 307(2010).

- Alinezhad, H.;Tajbakhsh, M.;Zare, M.Synth. Commun.,39: 2907( 2009).

- Heydari, A.; Khaksar, S.;Akbari, J.Esfandyari, M.;Pourayoubi, M.;.Tajbakhsh, M. Tetrahedron Lett.,48:1135( 2007).

- Heydari, A.;Arefi, A.;Esfandyari, M.J. Mol.Catal. A: Chem., 274: 169( 2007).

- Reddy, P. S.;Kanjilal, S.;Sunitha, S.; Prasad, R. B. N.Tetrahedron Lett.,48:, 8807(2007).

- Saidi, M. R.; Stan Brown, R.;Ziyaei-Halimjani, A.J. Iran. Chem. Soc.4:, 194 (2007).

- Cho, B. T.; Kang, S. K.Tetrahedron, 61:5725( 2005).

- Saxena, I.; Borah, R.;Sarma, J. C.J. Chem. Soc., Perkin Trans. 1, 503 (2000).

- Neidigh, K. A.; Avery, M. A.; .Williamson, J. S.; Bhattacharyya, S.J. Chem. Soc., Perkin Trans. 1, 2527 (1998).

- Varma, R. S.Dahiya, R.Tetrahedron Lett.,54:6293(1998).

- Brussee, J.; van Benthem,R. A.T.M.; Kruse, C.G.; Gen,A. v. d.Tetrahedron: Asymmetry, 1:163(1990).

- Setamdideh, D.; Hasani, S.; Noori, S. J. Chin. Chem. Soc.,60: 1267 (2013).

- Pourhanafi, S.;Setamdideh, D.; Khezri, B. Orient. J. Chem.29: 709 (2013).

- Setamdideh, D.; Karimi, Z.; Rahimi, F. Orient. J. Chem., 27: 1621(2011).

- Setamdideh, D.;Khezri, B.; Mollapour, M. Orient. J. Chem., 27: 991(2011).

- Setamdideh, D.;Khezri, B.;Rahmatollahzadeh, M.;Aliporamjad, A.Asian J. Chem. 24:3591(2012).

- Setamdideh, D.;Rafig, M.E-J. Chem.,9:2345 (2012).

- Setamdideh, D.;Rahmatollahzadeh, M.J. Mex. Chem. Soc.,56:169 (2012).

- Setamdideh, D.;Khezri, B.;Rahmatollahzadeh, M.J. Serb. Chem. Soc.,79:1 (2013).

- Mohamadi, M.; Setamdideh, D.;Khezri, B.Org. Chem. Inter., doi:10.1155/2013/127585 (2013).

- LatifiMmaghani, E.; Setamdideh, D. Orient. J. Chem.29: 953 (2013).

- Kamari, R.;Setamdideh, D.Orient. J. Chem.29: 497 (2013).

- Setamdideh, D.; Khaledi, L. S. Afr. J. Chem., 66: 150 (2013).

- Setamdideh, D.; Karimi, Z.; Alipouramjad, A. J. Chin. Chem. Soc., 60: 590 (2013).

- Zeynizadeh, B.;Setamdideh, D. Z. NaturforschB., 61b: 1275 (2006).

- Zeynizadeh, B.;Setamdideh, D. Synth. Commun.,36:2699 (2006).

This work is licensed under a Creative Commons Attribution 4.0 International License.