A Comparative Study of Sugar Mill Treated and Untreated Effluent- A Case Study

Weqar A. Siddiqui and Muhammad Waseem

Department of Applied Sciences and Humanities, Faculty of Engineering and Technology, Jamia Millia Islamia, New Delhi - 110 025, India.

Article Received on :

Article Accepted on :

Article Published : 31 Dec 2012

The treated and untreated effluent sample from Sir Shadi sugar mill Ltd. Shamli Distt Muzaffarnager of Western Utter Pradesh India during 2011-12 were collected and brought into laboratory for studying Physico-chemical parameters like Color, temperature, pH, DO, BOD, COD, TDS, TS, TSS, Chlorides, Sulphate and Oil & grease, heavy metals seed germination pattern of some important cereal crops. Untreated sugar mill effluent is found to have high contents of COD, BOD, TSS, TDS, and low contents of DO. Attempts were made to study the influence of sugar mill treated and untreated effluent on seed germination and seeding growth of cereal crops. The high concentration of distillery untreated effluents was found to inhibit the germination of cereal crops. According to the permissible limit suggested the Bureau of Indian Standards (BIS) the untreated effluents is toxic to plant so it is not permissible for irrigation. The results reflect that the treated effluents of sugar industry are not highly polluted and they satisfy the BIS Indian standards values and therefore can be used for irrigation purposes.

KEYWORDS:Sugar Mill effluent; Physico-chemical parameters; Seed germination; Heavy Metals; Irrigation

Download this article as:| Copy the following to cite this article: Siddiqui W. A, Waseem M. A Comparative Study of Sugar Mill Treated and Untreated Effluent- A Case Study. Orient J Chem 2012;28(4). |

| Copy the following to cite this URL: Siddiqui W. A, Waseem M. A Comparative Study of Sugar Mill Treated and Untreated Effluent- A Case Study. Available from: http://www.orientjchem.org/?p=22889 |

Introduction

The sugar mill in western Utter Pradesh, India is a key factor in rural economy of the state. Sugar factory is one of the most important agro based industry in India. India is the largest sugar producing country in the world. The sugar industry plays an important role in India’s economy. It is the second largest industry in the country, next to textiles and provides direct employment to more than 3.6 lakes person. The cultivation and transportation of sugarcane to the sugar mills provides a source of income to large number of farmers, laborers, technicians, and transport operators.

The main final products [1] of sugar cane industry are crystalline sugar and bio-ethanol. The latter is obtained from the fermentation and distillation of sugar cane juice and molasses. Quantitatively, the most significant by-product is bagasse, the solid residue from sugar cane after juice extraction and stillage (also called vinnasse or dunder), the liquid waste effluent after the distillation process of sugar cane juice. Sugar mill with annexed alcohol distilleries generally release an average of 155 l of stillage and 250 Kg bagasse per 1,000 Kg of sugar cane to obtain 12 l of alcohol and 95 Kg of sugar. Bagasse can be used in boilers during combustion, while stillage is mainly disposed to field crops, incorporating a risk for aquatic pollution. Surface water pollution potential is mainly due to the high contents of organic matters in stillage. Organic matters cause oxygen depletion by heterotrophic bio-degradation when enter in surface water. Stillage also contains high concentration of potassium which can accumulate at toxic levels in the soil. The objective of this study was to evaluate the Physico-chemical parameters, heavy metals and seed germination of treated and untreated effluent of sugar industry especially for irrigation purposes.

Material and Methods

For the present study the samples of treated and untreated effluent from a sugar industry located at Shamli western Utter Pradesh India were collected during the crushing session of 2011-12. A comprehensive study was carried out primarily data collection for the related work and secondary literature survey took place. Then to obtain basic ideas of the quality, characteristics and chemical composition of the effluent of sugar factory samples of treated and untreated effluents were collected in1 liter polythene-carbuoys bottle and mixed well in equal proportion to get homogeneous samples (Rain water and Thatcher, 1960) Random selection procedure was adopted for the selection of both sampling unit and the sampling point in given site (APHA1985). Tape water and 8 M HNO3 were used to wash the bottles, which were used for the sample preservation followed by washing them with distilled water and finally with double distilled water (Jeffery 1996). Then the bottles were rinsed thrice with effluent samples stored in refrigerator. Temperatures, pH, electrical Conductivity (EC) were measured at the sample collection site. Physico-chemical properties such as total dissolved solids (TDS) chemical Oxygen Demand (COD), chloride, TSS, TS, Sulphate and oil grease, heavy metals were measured using APHA standard method [9].

For physical and chemical analysis of the samples a number of sophisticated instruments were used and standard methods were followed. To measure the effluent parameters of the collected samples the Physico-chemical studies and heavy metals determinations were performed in sophisticated laboratory of Environmental Science lab, Faculty of Engineering & Technology, Jamia Millia Islamia New Delhi 110025.Heavy metal determination were performed using Atomic Absorption Spectrophotometer model 3100 (Perkin Elmer, USA).

For Studying germination pattern in treated and untreated effluents for different types of cereal crops seed viz Peniselium typhorides (Bajra), cicer arientinum (Chana), zea myes (Maize) and Triticum aestivum (wheat) were selected. Twenty five seeds of each were soaked in untreated effluent and another set in treated effluent as control for 24 hour in separate Petri dishes using filter paper method (Aggarwal 1995), the seeds were folded in germinating paper. Each paper contains 10 seeds. The folded paper along with seeds were tied with thread and kept in 500 ml beaker. 200 ml untreated effluent was poured in it, while another beaker was kept as control by using treated effluent. After every two days interval, water was added as per requirements depending upon rate of absorption. After seven days the germinated seeds were removed and then shoot & root lengths and weight of the seeding were measured and analyzed.

|

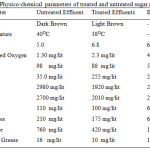

Table: 1 The Physico-chemical parameters of treated and untreated sugar mill effluent |

Result And Disscussion

Colour

According to the present study the colour of the untreated effluent was dark brownish and treated effluents appeared light brownish. Colour is very important factor for aquatic life for making food from sun rays. The photosynthesis activity is found to be reduced due to dark coloration also affecting other parameters like temperature DO and BOD etc.

Temperature

The effluent temperature plays an important role in making an effect on certain chemical and biological reactions taking place in water which affects organism and inhabitation of aquatic media. It depends upon season, time sampling etc. The water discharged from the industry which has generally high temperature, affects the land adversely. The temperature of untreated effluent was recorded 40OC and treated effluent was recorded 38 OC. The temperature of the discharge should not exceed 35 OC. The high tem i.e. 40OC of the untreated effluent has adversely affected the germination process.

pH

In the present investigation the pH value of treated and untreated were recorded as 5 and 6.8 respectively. According BIS standards the pH of the effluents should be in range 6.5 to 8.0.Relatively low pH values of both treated and untreated samples are due to use of phosphoric acid and Sulfur dioxide during cleaning of sugar cane juice. pH is one of the important biotic factor that serves as index for pollution. If such water is used for irrigation for a longer period the soil becomes acidic resulting in poor crops growth and yield. The factors like photosynthetic exposure to air, disposal of industrial effluent and domestic sewage also affect the pH of the soil.

Dissolved Oxygen

The analysis of DO is very important in water pollution control as well as waste water control. Aquatic ecosystem totally depends on DO, various biochemical changes and its effects on metabolic activities of microorganism were very well documented. Its presence was essential to maintain variety of forming of biological life in water and effect of water discharge in water body are largely determined by oxygen balance of the system. According to the BIS standard the DO of the effluent should be within the range 4 to 6 mg/lit. In the present investigation the DO of the untreated and treated effluent sample was recorded 1.30 and 2.30 mg/lit respectively which is sufficiently low than the BIS Indian standard (3) values.

BOD

Biochemical Oxygen Demand (BOD) is defined as amount of oxygen required by micro-organism while stabilizing biological decomposable organic matter in water under aerobic conditions. The biological oxidation is very slow process during oxidation; organic pollutants are oxidized by certain microorganism into carbon dioxide and water using dissolved Oxygen. Hence lowering in dissolved oxygen value is the measure of BOD relation. In the present investigation the BOD of the untreated effluent was 98 mg/l while the treated effluent recorded 88 mg/l. According to BIS Indian (3) standard the BOD should not exceed the 50 mg/l.

COD

The chemical Oxygen demand test determines the oxygen required for chemical oxidation of organic matter with the help of strong chemical oxidant. The COD is a test which is used to measure pollution of domestic and industrial waste. The effluent is measured in term of quality of oxygen required for oxidation of organic matter to produce carbon dioxide and water. It is a fact of all organic compounds with few exceptions that they can be oxidized by the action of strong oxidizing agents under acidic conditions. COD is useful in pinpointing toxic condition and presence of biological matters. In the present investigation the COD of the untreated effluents was 350 mg/l while treated effluent was recorded 255 mg/l. In untreated effluent it is appreciably high compared to BIS standard (250 mg/L). This indicated high organic pollutants in the sample.

TDS

The total dissolved solids concentration in the effluent represent the colloidal form and dissolved specters. The probable reason for the fluctuation or value of total solids and subsequent the value of dissolved solid due to convent collision of the colliding particles. The rate of collision aggregated process is also influenced by pH of this effluent. In the rainy season less concentration of total dissolved solids are obtain due to dilution of waste effluent with rain water (Hosetti et.al 1994.) In the present investigation the total solids in untreated effluent was 2980 mg/l and 1920 mg/l in treated effluent. In both the samples in TDS values are much higher compared to BIS Indian Standards (500 mg/L).

TSS

The total suspended solids affect the light intensity of water; suspended solids are the cause of suspended particle inside the water body influencing turbidity and transparency. According the present investigation the suspended solids of untreated effluent were 110 mg/l and 100 mg/l respectively.

Chlorides

The presence of chloride in natural water is attributed to dissolution of salt deposit, discharge of effluents from chemical industries oil well operations. In the present study chlorides of untreated was 210 mg/l and in treated effluent was recorded 175 mg/l. This is well within the limits of BIS Indian Standard.

Sulphate

Sulphate can also be produced by factorial or an oxidizing action as in the oxidation action or in the oxidation of oregano sulphur compounds. Sulphur itself has never been limiting factor in aquatic system, the normal levels of sulphate are more than adequate to meet plants needs. Odors conditions are easily greater when water is over loaded with organic wastes which reduce the oxygen, SO4 an electron acceptor is often used for the breakdown of organic matters and produces H2S causing bad smell of rotten egg (Welch 1980). In the present investigation sulphate in untreated effluent was 760 mg/l and treated effluent was recorded 420 mg/l according BIS Indian standard3 the sulphate should not exceed the 100 mg/l. High SO42- amount in both the effluents is attributed to the use of sulphur during crystallization

Oil And Grease

In the present investigation oil and grease present in untreated and traded effluent showed 16 mg/l and 10 mg/l respectively this is almost in accordance with the BIS Indian Standard.

Table 2: the effect of treated and untreated effluents on seed germination of some cereal crops.

| SN |

Characteristics |

Sample |

Bajra |

Gram |

Maize |

Wheat |

| 1 | Seed Germination (%) | Treated | 85.00 | 87.00 | 24.00 | 90.00 |

| Untreated | 05.00 | 20.00 | 82.00 | 30.00 | ||

| 2 | Root Length (cm) | Treated | 1.3±0.4 | 01.0±0.2 | 2.80±0.30 | 4.80±0.3 |

| Untreated | 0.00 | 0.30+0.1 | 3.10±0.3 | 00.20±0.1 | ||

| 3 | Shoot length (cm) | Treated | 00.60 | 2.20±0.2 | 0.311±02 | 5.10±0.2 |

| Untreated | 0.00 | 0.90±0.1 | 2.80±0.2 | 2.00±0.1 | ||

| 4 | Weight of the root (mg) | Treated | 00.21 | 00.70 | 1.30 | 00.25 |

| Untreated | 0.00 | 00.15 | 0.28 | 00.10 | ||

| 5 | Weight of shoot (mg) | Treated | 00.20 | 00.59 | 00.85 | 00.78 |

| Untreated | 0.00 | 00.30 | 00.21 | 00.25 |

The concentration of heavy metals in the sugar mill treated and untreated effluents are given in Table -3

| SN |

Metals |

Untreated Effluents |

Treated Effluents |

|

1 |

Cu (ppm) |

0.03 |

0.01 |

|

2 |

Cr (ppm) |

0.01 |

0.00 |

|

3 |

Cd (ppm) |

0.04 |

0.20 |

|

4 |

Co(ppm) |

0.08 |

0.50 |

|

5 |

Zn (ppm) |

1.40 |

1.13 |

|

6 |

Ni (ppm) |

0.09 |

0.05 |

The germination percentage values shown in the table-2 reveal the fact that percent germination of Bajra, Gram and wheat seeds is considerably high in treated effluent ie with the decreased concentration of undesirable matter compared to treated effluent. However a reverse trend is shown in the case of Maize, where 82% of seed germination is observed with untreated effluent with high concentration, while only 24 % of germination of Maize seed has been observed in treated water.

Maize seeds show the same trend while measuring the other parameters like root lengths, shoot length, weight of root and shoot (Table-2). While observing the germination process of Bajra, Maize and wheat seeds the lengths of roots and shoots are appreciably more in treated effluents compared the untreated effluent. In case of Maize seeds the lengths of roots and shoots both are mere in untreated effluent compared to treated effluent. After measuring the weight of roots and shoots of these germinated seeds it is obvious that except for maize seeds, considerably high germination have occurred with treated effluent. Osmotic pressure associated with higher concentration of untreated sugar factory effluent may have reduced the germination of seeds in untreated effluent.

Concentration of heavy metals like Cu, Cr, Cd, Co, Zn and Ni in treated and untreated effluents of sugar mill is listed in table-3. Results show that concentration of heavy metals in both treated and untreated effluent is below the permissible limit. Hence no effect of heavy metals on crops growth has been observed with treated and untreated effluents of sugar mill.

Conclusion

The sugar industry situated at shamli, Muzaffarnager western Utter Pradesh is one of the good factory as it has own distillery unit in its own premises for waste which is generated from the sugar factory. Even though the mill takes care to avoid pollution, additional measures for environmental protection initiated by the sugar industry with some modification in effluent treatment plant are necessary.

Thus the sugar industry effluent which is untreated exhibits high COD, BOD, TDS, contents and low contents of DO which is toxic to plants, so it is not permissible for irrigation. Treated effluent of sugar industry which is well balanced of chemicals if it is diluted with other fresh water, will be suitable for irrigation purposes. The treated effluents of sugar industry are not highly polluted and they satisfy the BIS Indian standard values.

REFRENCES

- Dr. A. S. Kolhe, Ingale S. R. & Sarode A.G. Physico Chemical Analysis of Sugar mill effluents, Sodh Samiksha auur Mulyankan (International Research Journal) ISSN-0974-2832 pp 307-311.

- D. Shivappa, E.T. Puttaiah and B R. Kiran Physico-chemical Characteristics of Sugar Mill Effluents-Current Scenario in Bhadrvathi Taluka, Karnatka, India Jr.of Industrial Pollution controls 23(2) 2007 pp 217-221.

- Rao T.B., Chonde S.G., Bhosale D.R. Jadhav A.S. and Raut P.D. Environmental Audit of sugar factory A Case Study of Kumbhi Kasari Sugar Factory, Khditre, Kolhapur Universal of Environmental Research and Technology 2011 Vol-1 pp 51-57.

- BIS 2010 Indian Standard specifications for drinking water IS: 10500 Bureau of Indian Standard New Delhi.

- A.S. Kohle, Ingale S.R. & Sarode A.G. Physico-chemical Analysis of Sugar Mill Effluents. S. S. M. International Research Journal Vol-1 pp (307-311).

- Amathussalam, M.N. Abubakar and N. Jayabai (2002). Impact of Sugar mill effluents on ground water, A case study Jr. of Industrial pollution 18(2) : 119-124.( c ).

- Gunter Gunkel , Jan Kosmol, Maria Sobral, Hendryk Rohn., Sugar cane Industry as a Source of Water Pollution-Case Study on the Situation in Ipojuca, Pernambuco, Brazil. Water Air Soil Pollutant (2007) 180:261-269 DOI 10.1007/s11270-0069268-x.

- N.J. Pawar, G.M. Pondhe, S.F. Patil, Groundwater Pollution due to sugar mill effluent, at Sonai, Maharashtra, India Environmental Geology 34 (2/3) May 1998 © Springer (pp 151-156).

- Standard methods for the examination of water and waste water, 1985, 16th Edition APHA, AWWA and WPCF Inc. New York.

This work is licensed under a Creative Commons Attribution 4.0 International License.