Synthesis of New Poly(Amide-Imide)S Derivatives Based on Amino Acid Compounds

Reza Soleymani1*, Milad Taheri2 and Marziye Hoseynalibeygi2

1Young Researchers Club, Shahre-rey Branch, Islamic Azad University, Tehran (Iran). 2Department of Chemistry, Shahre-rey Branch, Islamic Azad University, Tehran (Iran).

With condensation polymerization method in solution phase 31 new compound with polymerization property have been synthesized. These compounds derivate from amide-imides groups and obtained results indicate that they have high heat resistance (above 300 ºC). Obtained results show that also they have mechanisms with high yield in suitable speed. However, obtained poly(amide-imide)s derivatives have active light reactions and polarized light optical active. For identifying obtained structures have used of some methods like: 1H-NMR, FT-IR, mass spectroscopy and thermal gravimetric analysis (TGA) and elemental analysis. Some advantages of synthetic method is low synthetic levels and economically costs.

KEYWORDS:FT-IR; NMR; Poly (amide-imide)s; TGA; New Syntheses

Download this article as:| Copy the following to cite this article: Soleymani R, Taheri M, Hoseynalibeygi M. The One-Pot Three Components of Iodone, Schiff Base and Epoxide for Synthesis of Iodohydrins. Orient J Chem 2012;28(2). |

| Copy the following to cite this URL: Shameli A, Raeisi A. H, Pourhasan B, Naeimi H, Ghanbari M. M. The One-Pot Three Components of Iodone, Schiff Base and Epoxide for Synthesis of Iodohydrins. Available from: http://www.orientjchem.org/?p=23402 |

Introduction

Polymers consist of monomeric units that process has done in different compounds and with different methods. Chemical and physical parameters can lead to production of a polymer with unexpected molecular weight (less than normal range). Some physical parameters are as follows. Stirring quality, di amines sediments and polymer sediments 1.Some chemical factors include: range of material reactions with impurities and related acid receivers, other parameters like: impurities 2 and solvent activity 3 and side reactions 4-6. The most rapid reactions have a speed about 102-106 mol-1 sec-1 7-8. Solvent efficiency has significant influence on polymerization process. Most important parameters involve on the effects of solvents on polymerization process. These are including: solving primary materials for more mixing and contact, swelling agent of growing polymer, salvation of acid acceptor and its effecting formation of side salt products, polarized interactions with using solvent efficiency and absorbing heat of reactions by solvents polymerization mechanisms are done with swelling reagents for activating di carboxylic acids immediately and then condensation under the soft conditions. This method has done with three ways: a) Separable active intermediate is formed in a separation process and is purified before aminolysis. b) Intermediate acylation agent is formed through reaction of carboxylic acid and swelling reagent and then at the same time reacts with amine. c) Activeacylation agent in presence of an amine with augmentation of condensation reagent to amine and carboxylic acid 9-12. Today modified method (Yamazaki method) 10is used through condensation polymerization by phosphorylation. In this method, amino acids or aromatic di amines and aromatic di carboxylic acids in presence of an aryl phosphate (diphenyl and tri aryl phosphites) and an organic base like pyridine (C5H5N) as swelling reagents in N-methyl pyrrolidine (NMP) solvent including inorganic salts like LiCl and CaCl2. This lead to synthesis of polymers with high molecular weight. Effective parameters on polymers molecular weight are as follow: temperature, intrinsic solvent, monomer nature, monomer concentration effect and reagents and applied base, other condensation reagent, inorganic salts, solvent nature, stirring and homogeneous solution 13. Usually condensation polymerization reactions in solution are quick and irreversible 14. Effective variables on condensation polymerization of solution are divided into two groups: a) Properties and intrinsic specialties of pure materials. b) Selected physical conditions by operation in all of systems optimizing of all of these parameters are not necessary and presence of other parameter can compensate lack of another parameter 15. But poly(amide-imides)s as a subgroup of co poly imides have intermediate properties of these two polymers and maybe have the most similarity with the same poly-imides from heat properties view. They have high yield and are known for following reasons: thermal, chemical and mechanical stability an as processed polymers have high melting point and salvation. They derivate of Tumoplastic poly imides groups. They are widely used in various industrials like: covered electronic wires, glues, selectivity membranes and etc. in comparison with poly imides, poly amides and their homologues have better properties 16.One of the most important of commercial poly amide- poly imides is Turlon that is made from reaction of (tri mellitic anhydride chloride) with (4,4-diamino di phenyl methane). Turlon has good thermal stability, low dielectric constant, very low friction coefficient and high tensile strength. It has very low thermal expansion coefficient (260 ºC) and high creeping resistance in which lead to unique dimensional stability and high mechanical stiffness and other functions of Turlon lead to using in hardwares and electronic consumption. This polymer is amorphous and its TG is (280 ºC). The most important application of this polymer is in electronic micro chips and other device of computers. Today, poly (imide-amide)s are substituted in auto mobile, shuttles and electric industrial and microelectronic tools instead of metals or ceramic coating because of these polymers have good resistance in high temperatures and are known as new generation of plastics 17-20. There are various ways for synthesis of these compounds including: synthetic methods based on poly-amice-acid intermediates 21-23, swelling polymerization in low temperatures with other di amines 24, direct-condensation polymerization 25,26. But in this research for polymerization process in amides and imides direct-polymerization is used some new kinds of poly amide-poly imides derivatives obtained that the effects and application of these compounds will examined in the future.

Experimental Details

General method

All of necessary materials are purchased from Merck company (Germany) and are purified before application. Domestic-microwave system (Sumsung-2450 MHZ, 900W) is used for polymerization reactions. Magnetic resonance spectrum of hydrogen nucleus (1H-NMR) with 90 MHz was recorded by varian EM-390 and with 500 MHz was recorded by Brukeravance 500. Peak variation in magnetic resonance spectrum are shown with (s), (d), (dd) and (m). (TMS) IS used standard sample in NMR measurements. Infrared (IR) spectrum are recorded by (Shimadzo 435 IR spectrometer). IR are taken after preparation of (KBr) discs as sample and after preparing of thin film of sample on polished NaCl crystal. Vibrational transition frequencies are in wave number (cm-1). Absorbing bands are shown with: (w), (m), (sh), (s) and (br). Thermal gravimetric analysis (TGA) polymers was done by Mettler TGA-50 and with speeds: 10 ºC/min, 30 ºC/min, 40 ºC/min. elementary analysis of sample have done by CHN-RAPID (Heraeus).

Synthesis 2-(1-carboxy-2-methylpropyl)-1,3-dioxoisoindoline-5-carboxylic acidstructure

In a flask (25 mL) with refrigerant, magnetic stirring, 2.00 g (10.403- 10×mol) of trimellitic anhydride, 1,3-dioxo-1,3-dihydroisobenzofuran-5-carboxylic acid 1.39 g3- 10×10.4)mol) 2,3 –amino methylbutanoic acid and 24.00 mL acetic acid are mixed. This mixture were refluxed for 4 hours and then obtained mixture added to 20.00 mL of HCl (solution). After stirring for 2 hours, 20.00 mL of distilled water added and white 2-(1-carboxy-2-methylpropyl)-1,3-dioxoisoindoline-5-carboxylic acid was dried and purified. 2.54 g of 2-(1-carboxy-2-methylpropyl)-1,3-dioxoisoindoline-5-carboxylic acid with yield of 84% obtained. It recrystallized in methanol and water. Obtained crystals were white with melting point (193-194 ºC).to give (2.54 g, 84%);

A white dark compound; Mp 193-194 °C;IR (KBr): 2500-3580 (s, br), 2648 (m, sh),1700 (m), 1714 (s, br), 1605 (m), 1495 (m), 1405 (s), 1385 (s), 1293 (s), 1268 (s), 1207 (m), 1170 (m), 1150 (m), 1101 (m), 1070 (m), 1025 (w), 936 (w), 882 (m), 850(w), 805 (w), 774 (m), 733 (s), 710 (m), 658 (m), 610 (w), 574 (w), 535 (w) cm-1.1H-NMR (DMSO-d6, TMS, 90 MHz): δ 1.05-1.30 (dd,3H, J=7.50Hz), 1.70-1.05 (d, 3H, J=7.50Hz), 2.45-2.90 (m, 1H), 4.50-4.70 (d, 1H, J=7.5Hz), 6.20-7.80 (m, 2H), 8.50 (s, 1H, J=6.0Hz), 8.55-8.75 (d, 1H, J=6.0Hz) ppm; MS m/z 291, 249(85.69), 205 (14.80); Anal .Calcd for C14H13NO6: C, 57.73; H, 4.50; N, 4.81; O, 32.96. Found: C, 57.95; H, 4.23; N, 4.52; O, 34.96.

Synthesis 5a Structure

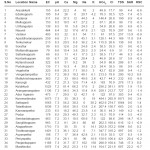

New poly (amide-imide)s optical activity 1a to 7a were done from polymerization of diacid 2-(1-carboxy-2-methylpropyl)-1,3-dioxoisoindoline-5-carboxylic acid with aromatic diamines according to (table1). For instance: for pre paring of polymer 5a, 0.10 g (3.43×10-4mol) 2-(1-carboxy-2-methylpropyl)-1,3-dioxoisoindoline-5-carboxylic, 0.08 g (3.43×10-4mol) diamine according to (table 1), 0.10 g CaCl2, 0.33 mL (1.27×10-4mol) TPP, 0.29 mL pyridine and 0.60 mL (NMP) were added into a flask (10 mL) with refrigerant drying tube, magnetic stirring. This mixture was heated for 30 minutes in 60 ºC for 2 hours in 90 ºC and for 8 hours in 130 ºC. Then resulted viscous solution was cooled and ten diluted with some (DMF) solvent and by dropper was added to 50.00 mL of hot methanol. Obtained sediment was purified and was dried in vacuum condition for 15 hours in 100 ºC. 0.174 g polymer 5a obtained with yield of 92%.to give 5a (0.174 g, 92%);

|

Table 1: Click here to View table |

A white compound; thermistor property 300 °C; IR (KBr): 3550 (m), 3300 (m, br), 3110 (m, sh), 2955 (m), 2811 (m, sh), 1775 (m), 1712 (s), 1680 (s, sh), 1590 (s), 1520 (s), 1490 (s, sh), 1429(w, sh), 1400 (m), 1388 (s), 1318 (s), 1250 (s), 1180 (m, sh), 1155 (s), 1102 (s), 1075 (m), 1011 (w), 942 (w), 888(w), 830 (m), 722 (s), 693 (m), 626 (w, sh), 555 (m, br) cm-1; MS m/z 521, 506(21.69), 462 (69.60), 386 (35.58); Anal. Calcd for C26H23N3O7S: C, 62.02; H, 4.45; N, 8.34; O, 21.47; S, 6.15.Found: C, 59.88; H, 4.29; N, 8.06; O, 20.57; S, 6.35.

Synthesis 1a structure

to give 1a (1.42 g, 85%); A yellow compound; IR (KBr): 3305 (m, br), 3095 (m, sh), 2955 (m), 1776 (m), 1728 (s), 1670 (s), 1614 (m), 1548 (m, sh), 1510 (s), 1479 (m, sh), 1433 (m, sh), 1408 (m), 1375 (s), 1317 (s), 1255 (m), 1181 (m, sh), 1082 (m), 1001 (w), 949 (s), 835 (m), 724 (s), 522 (w) cm–1; MS m/z 381, 351(45.23), 336(12.85), 260(76.58); Anal. Calcd for: C20H19N3O5:C, 66.11; H, 4.88; N, 11.56; O, 20.98. Found: C, 65.41; H, 5.01; N, 10.85; O, 21.88.

Synthesis 2a structure

to give 2a (1.54 g, 89%); A white dark compound; IR (KBr): 3300 (m, br), 3080 (m, sh), 2970 (m), 1775 (m), 1715 (s), 1670 (s), 1590 (s), 1530 (s), 1490 (s), 1470 (m, sh), 1375 (s), 1280 (m), 1250 (m), 1190 (m), 1160 (m), 1070 (m), 1020 (m), 1000 (w), 950 (s), 910 (m), 820 (w), 760 (m), 720 (s), 680 (m), 580 (w) cm-1; MS m/z 395, 381(46.19), 351(24.64), 336(16.68); Anal. Calcd for: C21H21N3O5:C, 65.83; H, 5.07; N, 11.13; O, 20.23. Found: C, 64.96; H, 5.35; N, 10.67; O, 21.13.

Synthesis 3a structure

to give 3a (1.98 g, 90%); A green dark complexes; IR (KBr): 3306 (m, br), 3085 (m, sh), 2965 (m), 17775 (m), 1725 (s), 1675 (s), 1605 (m), 1535 (s), 1496 (s), 1418 (m), 1385 (s), 1334 (m), 1266 (m), 1255 (m), 1195 (m), 1076 (m), 944 (w), 906 (w, sh), 865 (w), 784 (m), 729 (s), 688 (w), 580 (w) cm-1; MS m/z 431, 416(39.19), 386(15.70), 372(87.38); Anal. Calcd for: C24H21N3O5; C, 69.72; H, 4.93; N, 10.16; O, 18.57.Found: C, 68.37; H, 4.59; N, 9.74; O, 17.57.

Synthesis 4a structure

to give 4a (2.12 g, 97%); A white compound; IR (KBr): 3303 (m, br), 3082 (m, sh), 2994 (m), 1776 (m), 1715 (s), 1666 (s, sh), 1609 (s), 1535 (s), 1482 (s), 1477 (s), 1370 (s), 1305 (m, sh), 1256 (m), 1079 (m), 1021 (w), 933 (w), 872 (w), 785 (m), 723 (s), 684 (m), 581 (w), cm-1; MS m/z 381, 366(54.19), 336(57.24), 322(27.58); Anal. Calcd for: C20H19N3O5:C, 66.20; H, 4.71; N, 11,56; O, 20.98. Found: C, 64.80; H, 5.03; N, 11.04; O, 22.13.

Synthesis 6a structure

to give 6a (2.14 g, 97%); A yellow dark compound; IR (KBr): 3300 (m, br), 3048 (m, sh), 2951 (m), 1775 (m), 1716 (s), 1677 (s), 1606 (s), 1532 (s, sh), 1518 (s), 1437 (m, sh), 1404 (s), 1388 (s), 1314 (s), 1248 (s), 1180 (m), 1100 (m, sh), 1074 (m), 1016 (w), 943 (w), 912 (w), 858 (w), 811 (m), 765 (m), 723 (s), 602 (w), 505 (w) cm-1; MS m/z 471, 456(54.16), 426(87.12), 412(45.28); Anal. Calcd for: C27H25N3O5; C, 71.51; H, 5.11; N, 9.26; O, 16.97.Found: C, 68.94; H, 5.34; N, 8.91; O, 15.87.

Synthesis 7a structure

to give 7a (2.10 g, 96%); A yellow dark compound; IR (KBr): 3300 (m, br), 3105 (m, sh), 2959 (m), 1775 (m), 1715 (s), 1666 (s, sh), 1604 (m), 1533 (m, sh), 1504 (s), 1468 (m, sh), 1415 (m), 1355 (m, sh), 1226 (s), 1165 (m), 1101 (m, sh), 1072 (m), 1011 (w), 934 (m), 855 (w, sh), 825 (m), 760 (m), 726 (s), 685 (w), 504 (w, br) cm-1; MS m/z 473, 458(18.19), 428(32.20), 414(30.58); Anal. Calcd for: C26H23N3O6; C, 68.56; H, 4.90; N, 9.22; O, 20.27. Found: C, 67.94; H, 4.55; N, 8.97; O, 21.37.

Synthesis of 2-(1-carboxy-2-methylbutyl)-1,3-dioxoisoindoline-5-carboxylic acidstructure

In a flask (25 mL) equipped with magnetic stirring 0.15 g (7.806×10-4mol) (tri mellitic anhydride)-1,3-dioxo-1,3-dihyroisobenzofuran-5-carboxylic acid, 0.10 g (7.806×10-4mol) Isoleucine 2-amino-3-methylpentanoic acid was added to 2.00 mL (DMF) and were refluxed for 4 hours. Then obtained solution was added to 20.00 mL dilute HCl (10%) and obtain white sediment of 2-(1-carboxy-2-methylbutyl)-1,3-dioxoisoindoline-5-carboxylic aid. This sediment dried in vacuum condition and purified. Compound of 2-(1-carboxy-2-methylbutyl)-1,3-dioxoisoindoline-5-carboxylic acid resulted with yield of 76% and weight (0.18 g). It was easily recrystallized in methanol and water and formed white crystals. Melting point of this compound is (195-197 ºC).

to give (0.18 g, 76%); A white dark compound; Mp 195-197°C; IR (KBr): 2700-3700 (s, sh), 2809 (s, br), 1788 (s, sh), 1704 (s, br), 1609 (m, sh), 1488 (m), 1466 (m),1425 (m), 1387 (s), 1344 (s, sh), 1285 (s), 1263 (m, sh), 1203 (m), 1171 (m), 1151 (m, sh), 1092 (m), 1022 (w), 962 (w, sh), 933 (m), 888 (m), 800 (w), 768 (m), 735 (s), 704 (m), 651 (m), 574 (w), 533 (w), cm-1. 1H-NMR ( DMSO-d6, TMS, 90MHz ): d 0.70-1.09 (t, 3H, J = 6.0 Hz), 1.10-1.30 (d, 3H, J = 6.0 Hz), 1.37-2.70 (m, 3H), 4.55-4.80 (d, 1H, J = 6.9 Hz), 8.50-8.75 (m, 2H, J = 6.30 Hz), 8.00-9.80 (s, 2H) ppm; MS m/z 305, 263(85.69), 249(58.80), 205(16.13); Anal. Calcd for C15H15ON6: C, 59.01; H, 4.95; N, 4.59; O, 31.45. Found: C, 59.28; H, 4.55; N, 5.04; O, 32.48.

Synthesis of 1b structure

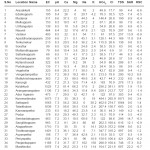

Optical activity of poly (amide-imides) 1b to 7b are prepared with direct condensation polymerization of monomer 2-(1-carboxy-2-methylbutyl)-1,3-dioxoisoindoline-5-caboxylic acid and aromatic di amines according to (table 2) in long time and with graduate temperature. For instance, for preparation of 1b polymer, 0.10 g (3.27×10-4mol) di acid 2-(1-carboxy-2-methylbutyl)-1,3-dioxoisoindoline-5-caboxylic acid, 0.03 g of diamine (1e) (3.27×10-4mol), 0.100 g of calcium chloride (CaCl2), 0.33 mL of TPP (1.27×10-3mol), 0.29 mL of pyridine, 0.50 mL of N-methyl pyrrolidine (NMP) in a flask (10 mL) equipped with claisen adapter, refrigerant, drying tube, magnetic stirring. This mixture reacted under the nitrogen atmosphere for 30 minutes in 60 ºC, for 2 hours in 90 ºC and for 8 hours in 130 ºC. resulting viscous solution was diluted with 2.00 mL of (DMF) and then cooled and by dropper added to 50.00 mL of methanol. 1b polymer produced yellow wish sediment in methanol. The sediment was purified and for 15 hours was dried under the vacuum condition in 100 ºC. 0.114 g polymer 1b obtained with yield of 92%.

|

Table 1: Click here to View table |

to give 1b (0.114 g, 92%); A yellow dark compound; IR (KBr): 3300 (m, br), 3100 (m, sh), 2950 (m), 1770 (m), 1710 (s), 1650 (s), 1600 (m), 1540 (m, sh), 1505 (s), 1460 (m, sh), 1430 (w), 1400 (m), 1370 (s), 1330 (s), 1250 (m), 1170 (m), 1070 (m), 1020 (w), 940 (m), 900 (w), 830 (m), 760 (w), 720 (s) cm-1; MS m/z 395, 380(97.00), 350(45.15), 336(78.58); Anal. Calcd for C21H21N3O5: C, 66.73; H, 5.07; N, 11.13; O, 20.23. Found: C, 66.04; H, 5.35; N, 10.63; O, 21.45.

Synthesis of 2b structure

to give 2b (1.54 g, 98%); A white dark compound; IR (KBr): 3300 (m, br), 2935 (m), 1775 (m), 1714 (m), 1650 (s), 1595 (s), 1521 (s), 1505 (s),1366 (s), 1250 (m), 1199 (m, sh), 1180 (m), 1086 (m), 1025 (m), 1000 (w), 945 (m), 904 (m), 860 (w, sh), 825 (w), 760 (m), 728 (s), 680 (m) cm-1; MS m/z 409, 379(48.19), 365(87.80), 336(56.19); Anal. Calcd for C22H23N3O5: C, 67.41; H, 5.41; N, 10.73;O, 19.45. Found: C, 67.56; H, 5.66; N, 10.26; O, 18.54.

Synthesis of 3b structure

to give 3b (0.2 g, 93%); A green compound; IR (KBr): 3308 (m, br), 3070 (m), 2955 (m), 1770 (m), 1719 (s), 1679 (s), 1628 (m,sh), 1600 (m), 1529 (s), 1498 (s), 1485 (s, sh), 1416 (m), 1375 (s), 1336 (s), 1268 (m), 1255 (m), 1196 (m), 1075 (m), 940 (w), 905 (w), 865 (w), 790 (m), 722 (s), 683 (w) cm-1; MS m/z 445, 415(58.19), 401(75.98), 386(98.00); Anal. Calcd for C25H23N3O5: C, 70.25; H, 4.95; N, 9.83; O, 17.95. Found: C, 68.61; H, 4.90; N, 9.46; O, 17.45.

Synthesis of 4b structure

to give 4b (1.22 g, 97%); A white dark compound; IR (KBr): 3302 (m, br), 3051 (m, sh), 2952 (m), 1775 (m), 1710 (s), 1665 (s, sh), 1604 (s), 1522 (s), 1508 (s), 1425 (s), 1375 (s), 1304 (s, sh), 1256 (m), 1165 (m), 1075 (m), 940 (w), 850 (w), 778 (m), 725 (s), 686 (m) cm-1; MS m/z 395, 365(38.97), 351 (45.70), 336(54.58); Anal. Calcd for C21H21N3O5: C, 66.93; H, 5.17; N, 11.13; O, 20.23. Found: C, 66.74; H, 5.23; N, 10.68; O, 19.95.

Synthesis of 5b structure

to give 5b (0.4 g, 93%); A white compound; IR (KBr): 3300 (m, br), 2908 (m), 1789 (m), 1711 (s), 1654 (s), 1580 (s), 1515 (s), 1496 (s), 1383 (s), 1302 (s), 1250 (s), 1176 (m, sh), 1145 (s), 1095 (s), 1074 (s, sh), 1026 (m, sh), 930 (m, sh), 839 (m), 724 (s), 680 (m), 551 (m) cm-1; MS m/z 535, 505(28.69), 491(14.80), 476(26.58); Anal. Calcd for C27H25N3O7S: C, 62.76; H, 4.78; N, 8.12; O, 20.91; S, 5.99. Found: C, 62.64; H, 4.41; N, 7.81; O, 21.51; S, 5.78.

Synthesis of 6b structure

to give 6b (0.10 g, 83%); A yellow dark compound; IR (KBr): 3300 (m, br), 3059 (m, sh), 2957 (m), 1785 (m), 1714 (s), 1652 (s), 1603 (s), 1521 (s, br), 1514 (s), 1496 (m, sh), 1465 (m, sh), 1405 (m), 1375 (s), 1310 (s), 1250 (m), 1180 (m), 1072 (m), 1025 (w), 944 (m), 910 (w), 856 (w), 819 (m), 767 (m), 720 (s), 688 (w) cm-1; MS m/z 485, 455(35.54), 441(87.58), 426(91.18); Anal. Calcd for C28H27N3O5: C, 71.78; H, 5.39; N, 8.88;O, 16.48. Found: C, 72.27; H, 5.64; N, 8.53; O, 17.91.

Synthesis of 7b structure

to give 7b (1.24 g, 97%); A yellow compound; IR (KBr): 3300 (m, br), 3050 (m, sh), 2950 (m), 1770 (m), 1710 (s), 1670 (s, sh), 1600 (m), 1520 (m, sh), 1490 (s), 1400 (m, sh), 1360 (m), 1310 (m), 1210 (s), 1090 (m, sh), 1065 (m), 1005 (w), 940 (m), 870 (w, sh), 820 (m), 750 (m), 720 (s), 680 (w) cm-1; MS m/z 487, 457(98.69), 443(18.80), 428(36.18); Anal. Calcd for C27H25N3O6: C, 69.47; H, 4.94; N, 8.95; O, 19.68. Found: C, 68.50; H, 4.83; N, 8.62; O, 20.48.

Synthesis 2e reactant

In a round-bottomed flask (25 mL) equipped with refrigerant and drying tube, 1.00 g of pyro mellitic di anhydride (4.58×10-3mol), 1.07 g (9.16×10-4mol) 2-amino-3-methylbutanoic acid and 15.00 mL of acetic acid pot on a magnetic stirring. This mixture was stirring at room temperature for 5 hours and then was refluxed in boiling temperature of solvent for 6 hours. Then 25.00 mL of diluted HCl (10%) cooled and obtained mixture was stirring at room temperature for 1 hours. White sediment was purified and dried for 10 hours in 80 ºC under the vacuum condition. Finally, have (2e) with yield of 92% and weight of 1.75 g. This compound easily recrystallized in methanol and water. At the end, white crystal formed. Melting point of di acid optical active was (265-267 ºC).

to give 2e (1.75 g, 92%); A white dark compound; Mp 265-267°C;IR (KBr): 2450-3500 (s, br), 1766 (s, sh), 1728 (s, br), 1468 (m), 1447 (m), 1389 (s), 1366 (s), 1263 (s), 1152 (m), 1085 (s), 1024 (m), 896 (s), 826 (m), 786 (m), 725 (s), 624 (m) cm-1.1H-NMR (DMSO-d6, TMS, 90 MHz)δ: 0.8-1.3 (d,12H), 2.5-2.9 (m, 2H), 4.5(d, 2H, J = 9 Hz), 11.3 (s, 2H) ppm; MS m/z 416, 388 (87.19), 330 (54.10), 316 (78.48); Anal. Calcd for C20H20N2O8: C, 57.58; H, 5.99; N, 6.85; O, 30.68. Found: C, 57.69; H, 5.84; N, 6.73; O, 30.4.

Synthesis 3e reactant

In a round-bottomed flask (25 mL) equipped with refrigerant and drying tube, 0.50 g (1.20×10-3mol) di acid 2e and 4.00 mL of thionyl chloride put on a magnetic stirring. This mixture were reacted in room temperature for 2 hours and then refluxed for 1 hours. Then excess thionyl chloride omitted with vacuum distillation and rest of this reaction rinsed with (n-Hexane). 0.53 gr of production with yield of 0.98%.melting point of this product was (134-140 ºC).

to give 3e (0.53 g, 0.98%); A white dark compound; Mp134-140°C; IR (KBr): 3110 (w), 2953 (s), 2905 (m), 1823 (s, sh), 1790 (s), 1728 (s, br), 1469 (s), 1388 (s), 1369 (s), 1346 (s), 1276 (m), 1254 (w), 1152 (s), 1120 (m), 1084 (s), 1050 (s), 1024 (m), 995 (m), 911 (s), 863 (m), 842 (m), 814 (m), 777 (s), 730 (s), 620 (s), 580 (w) cm-1; MS m/z 452, 424(78.19), 348(36.87), 334(16.18); Anal. Calcd for C20H18Cl2N2O6: C, 53.08; H, 4.89; N, 6.18;O, 21.18; Cl, 15.64. Found: C, 52.69; H, 5.24; N, 6.73;O, 21.08; Cl, 14.89.

Synthesis of 1c structure

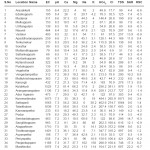

Polymerization of di acid chloride (3e) with aromatic amines in above condition have done (table 3). For instance, for preparation of polymer (1c) in a crucible, 0.10 g (2.20×10-4mol) (3e) and 0.02 g (2.20×10-4mol) di amine (1c) put in and after complete abrade for 5 minutes, when mixture of reactants became powder, 0.10 mL of orthocorsol as solvent added to reaction system. After complete erosion of reactants for 3 minutes 0.04 mL of (TMSCl) added and this reaction was abraded for 3 minutes. Then reactant mixtures influenced with radiation of microwave with potentials by of 100% for 6 minutes. Forming film polymer with increasing of 20 mL methanol and erosion, was separated and after purification, under the vacuum condition dried at 80 ºC for 10 hours. Obtained polymer was with yield of 61% and weight of 0.07 g.

|

Table 1: Click here to View table |

to give 1c (0.07 g, 61%); A yellow dark compound; IR (KBr): 3305 (m, br), 2952 (m), 1770 (s), 1724 (s, br), 1612 (m), 1513 (s), 1462 (m), 1380 (s), 1351 (s), 1304 (s), 1249 (m), 1157 (m), 1084 (s), 1006 (w), 925 (m), 832 (m), 723 (s), 622 (w) cm-1.1H NMR (DMSO-d6, TMS, 500 MHz): d 0.86-0.87 (d, 3H, J = 5.86 Hz), 1.04-1.05 (d, 3H, J = 5.82 Hz), 2.83 (m, 1H), 3.98-4.10 (m, 1H, J = 7.56 Hz), 4.58-4.60 (d, 1H, J = 7.98 Hz), 7.46 (s, 1H), 8.31 (s, 1H), 9.99 (s, NH), 10.21-10.68 (s, 1H) ppm; MS m/z 506, 491(88.20), 463(20.87), 449(11.18); Anal. Calcd for C26H26N4O7: C, 63.93; H, 4.95; N, 11.47;O, 19.98. Found: C, 64.42; H, 5.46; N, 12.34;O, 16.68.

Synthesis of 2c structure

to give 2c (0.11g, 85%); A yellow compound; IR (KBr): 3300 (m, br), 2935 (s), 1777 (s), 1728 (s), 1604 (s), 1520 (s), 1450 (m), 1389 (s), 1356 (s), 1215 (m), 1144 (m), 1080 (s), 1005 (w), 916 (w), 861 (m), 810 (m), 725 (s), 654 (w), 624 (w) cm-1; MS m/z 520, 505(78.19), 491(36.87), 463(16.18); Anal. Calcd for C27H28N4O7: C, 64.53; H, 5.21; N, 12.15; O, 15.38. Found: C, 64.46; H, 5.88; N, 13.45; O, 16.68.

Synthesis of 3c structure

to give 3c (0.09 g, 70%); A white dark compound; IR (KBr): 3303 (m, br), 2938 (m), 1777 (s), 1729 (s), 1601 (s), 1535 (s), 1481 (s), 1422 (s), 1385 (s), 1346 (s), 1307 (m, sh), 1204 (m), 1155 (m), 1076 (m), 1004 (w), 911 (w), 862 (w), 780 (m), 725 (s), 680 (m), 624 (w), 566 (w) cm-1; MS m/z 506, 491(89.32), 463(46.17), 449(78.20); Anal. Calcd for C26H26N4O7: C, 63.93; H, 4.85; N, 11.57; O, 16.08. Found: C, 64.41; H, 5.08; N, 11.14; O, 16.58.

Synthesis of 4c structure

For instance have is presented preparing method of poly (amide-imide 4c). In a round-bottomed flask (5 mL) equipped with drying tube, 0.10 g of di acid chloride (2.21×10-4mol) according to table 3, 0.05 g (2.21×10-4mol) di amine, 0.04 mL tri methyl silyl chloride (TMSCl) and 0.02 mL N,N-di methyl acetamide (DMAC) added (Table 3). This mixture was refluxed for 8 minute. After reaching reaction temperature to room temperature, obtained viscous solution added to 30.00 mL (methanol) and then system temperature reached to room temperature and was stirring for 5 hours. Resulting viscous solution added to 30.00 mL of methanol and polymer sedimentation was dried in 80 ºC for hours. Yield of reaction was 94.00%and polymer weight was (5c) 0.13 g.

to give 4c (0.13 g, 94%); A yellow compound; IR (KBr): 3308 (m, br), 2951 (s), 1773 (s), 1724 (s, br), 1594 (s), 1525 (s), 1461 (m), 1380 (s), 1345 (s), 1317 (m, sh), 1244 (m), 1153 (s), 1102 (s), 1075 (m), 910 (w), 835 (m), 724 (s), 625 (m), 560 (w), cm-1; MS m/z 646, 631(85.11), 603(36.87), 589(24.25); Anal. Calcd for C32H30N4O9S: C, 61.24; H, 4.89; N, 8.91; O, 16.58. Found: C, 61.45; H, 5.78; N, 9.45;O, 16.08.

Synthesis of 5c structure

to give 5c (0.098 g, 77%); A yellow dark compound; IR (KBr): 3305 (m, br), 2954 (m), 1775 (s), 1726 (s), 1604 (s), 1510 (s), 1467 (m), 1416 (m), 1381 (s), 1344 (s), 1240 (m), 1150 (m), 1074 (s), 1013 (w), 912 (m), 810 (m), 724 (s), 622 (w) cm-1; MS m/z 596, 581(56.20), 553(21.41), 539(45.99); Anal. Calcd for C33H32N4O7: C, 68.50; H, 5.23; N, 9.68; O, 12.36.Found: C, 68.38; H, 5.76; N, 10.82; O, 11.28.

Synthesis of 6c structure

For instance here present preparing method of 7c poly (amide-imide). In a round-bottomed flask equipped with drying tube, 0.04 g (2.21×10-4mol) of di amine added to 0.50 of NMP (Table 5). After complete salvation of di amine, reaction temperature reduced to (-5 ºC). through stirring 0.10 g (2.21×10-4mol) (3e) added. After reactant salvation, 0.04 mol of (TMSCl) added and at the -5 ºC reaction under the nitrogen atmosphere was stirring for 4 hours. Then system temperature reached to room temperature and was stirring for 5 hours. Resulting viscous solution added to 25.00 mL of methanol and obtained polymer was purified and under the vacuum condition was dried at 80 ºC for 10 hours. Yield of reaction was 89% and polymer amount was 0.11 g.

|

Table 1: Click here to View table |

to give 6c (0.11 g, 89%); A yellow compound; IR (KBr): 3604 (s), 3306 (m), 2990 (m), 2988 (m, sh), 1775 (s), 1720 (s), 1600 (s), 1532 (s, sh), 1501 (s), 1463 (m), 1404 (m, sh), 1389 (s), 1344 (s), 1305 (m, sh), 1227 (s), 1155 (m), 1064 (s), 1004 (w), 913 (w), 824 (s), 727 (s), 627 (m) cm-1.1H NMR (DMSO-d6, TMS, 500 MHz) d: 0.86-0.87 (d, 3H, J = 5.45 Hz), 1.04-1.05 (d, 3H, J = 5.41 Hz), 2.84 (m, 1H), 3.68-4.02 (m, 1H, J = 7.56 Hz), 4.59-4.61 (d, 1H, J = 8.00 Hz), 6.90-6.92 (d, 1H, J = 8.25 Hz), 7.49-7.5 (d, 1H, J = 8.35 Hz), 8.33 (s, 1H), 10.04 (s, NH), 10.45-11.02 (s, 1H) ppm ; MS m/z 598, 583 (77.11), 555 (12.98), 541 (45.56); Anal. Calcd for C32H30N4O8: C, 66.20; H, 4.86; N, 9.65; O, 16.39. Found: C, 67.70; H, 4.94; N, 10.76;O, 16.36.

Synthesis 3f reactant

In a round-bottomed flask (25 mL) equipped with refrigerant and drying tube, 0.10 g (2.25×10-4mol) (2f) and 2.50 mL excessive thionyl chloride put on a magnetic stirring. This mixture reacted and refluxed for 2 hours. Then excessive thionyl chloride with vacuum distillation omitted and rest of reaction rinsed with (n-Hexane) 3 times. Yield of reaction was 97% and resulted production was 0.105 g.

to give 3f (0.105 g, 97%); A white dark compound; Mp 143-144°C; IR (KBr): 2955 (m), 2904 (m), 1811 (s), 1799 (s), 1778 (s), 1457 (m), 1384 (s), 1363 (s), 1150 (m), 1122 (m), 1080 (s), 1012 (m), 895 (m), 804 (w), 760 (w), 739 (s), 635 (w), 604 (m) cm-1; MS m/z 480, 438(58.20), 362(12.98), 348(89.16); Anal. Calcd for C22H22Cl2N2O6: C, 54.89; H, 4.61; N, 5.82; O, 19.94; Cl, 14.73. Found: C, 54.94; H, 4.87; N, 5.65; O, 18.74; Cl, 15.83.

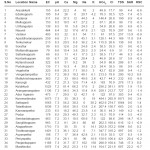

Synthesis of 1d structure

3f polymerization (di acid chloride) were done with aromatic di amines in above conditions. For example, for preparation of 1d polymer, in a crucible, 0.10 g (2.07×10-4mol) 3f and 0.02 g (2.07×10-4mol) various di amine added and after complete erosion for 5 minutes, when all of reactants became powder, 0.10 mL (NMP) was added as solvent to reaction system. After complete erosion of reactants for 5 minute this mixture was reacted under the radiation with microwave by potentiality of 50% obtained film polymer with increasing of 20.00 mL methanol and erosion, it was separated and under the vacuum conditions dried at 80 ºC for 10 hours. Yield of this reaction was 80% and resulting polymer is 0.20 g.

to give 1d (0.20 g, 80%); A yellow dark compound; IR (KBr): 3300 (m, br), 2958 (s), 1779 (s), 1722 (s, br), 1601 (m), 1523 (m, sh), 1501 (s), 1465 (m), 1419 (m), 1380 (s), 1343 (s), 1220 (s), 1154 (m), 1105 (m), 1070 (m), 1011 (w), 914 (w), 852 (m), 830 (s), 720 (s), 620 (w), 560 (w) cm-1. 1H- NMR (DMSO-d6, TMS, 500 MHz ) d: 0.82 (s, br, 3H), 0.99 (m, 3H), 1.50 (s, br, 2H), 2.63 (s, br, 1H),3.54-4.12 (m,1H,J = 7.56 Hz), 4.71-4.73 (d, 1H, J = 7.60 Hz), 7.74-7.76 (d, 1H, J = 7.75 Hz), 7.82-7.84 (d, 1H, J = 7.85 Hz), 8.29-8.31 (s, 1H), 10.45-10.50 (s, NH), 10.69-11.00 (s, 1H) ppm; MS m/z 534, 519(89.31), 477(54.55), 463(35.16); Anal. Calcd for C28H30N4O7: C, 65.11; H, 5.46; N, 10.85; O, 15.37. Found: C, 65.33; H, 5.81; N, 11.45; O, 14.17.

Synthesis of 2d structure

to give 2d (0.045 g, 52%); A yellow compound; IR (KBr): 3303 (m, br), 2920 (s), 1774 (s), 1725 (s, br), 1668 (s), 1600 (m), 1525 (m), 1494 (m), 1453 (m), 1386 (s), 1340 (s), 1317 (m), 1148 (m), 1107 (m, sh), 1079 (s), 1000 (w), 911 (w), 867 (m), 821 (m), 722 (s), 650 (w), 626 (w), 564 (w) cm-1; MS m/z 548, 533(69.10), 477(78.52), 463(33.56); Anal. Calcd for C29H32N4O7: C, 65.65; H, 5.69; N, 10.56; O, 14.77. Found: C, 64.81; H, 6.11; N, 11.19; O, 13.87.

Synthesis of 3d structure

to give 3d (0.079 g, 61%); A white dark compound; IR (KBr): 3307 (m, br), 2954 (s), 1770 (s), 1721 (s, br), 1605 (s), 1534 (s), 1489 (s), 1428 (s), 1380 (s), 1346 (s), 1213 (m), 1150 (m), 1105 (m, sh), 1081 (s), 1000 (w), 910 (w), 865 (m), 764 (m), 723 (s), 687 (m), 624 (w), 561 (w) cm-1; MS m/z 534, 519(32.89), 443(45.98), 429(76.12); Anal. Calcd for C28H30N4O7: C, 65.41; H, 5.36; N, 10.85;O, 15.77. Found: C, 64.38; H, 5.82; N, 11.58; O, 15.37.

Synthesis of 4d structure

to give 4d (0.10 g, 91%); A white dark compound; IR (KBr): 3308 (m, br), 2954 (s), 1771 (s), 1720 (s, br), 1593 (s), 1525 (s), 1464 (m), 1407 (s, sh), 1389 (s), 1347 (s), 1318 (s, sh), 1247 (m), 1185 (m), 1152 (s), 1075 (s), 1104 (s), 1075 (s), 1010 (w), 900 (w), 830 (m), 720 (s), 680 (m), 621 (m), 555 (m) cm-1; MS m/z 674, 659(77.11), 597(12.98), 583(45.56); Anal. Calcd for C34H34N4O9S: C, 62.28; H, 4.91; N, 8.63; O, 17.67; S, 7.09. Found: C, 61.03; H, 5.24; N, 9.55; O, 16.77; S, 8.19.

Synthesis of 5d structure

to give 5d (0.119 g, 96%); A yellow compound; IR (KBr): 3308 (m, br), 2950 (s, br), 1725 (s, br), 1673 (s, sh), 1606 (m), 1513 (s), 1468 (m), 1417 (m), 1384 (s), 1346 (s), 1250 (m), 1182 (m), 1154 (m), 1100 (m), 1070 (s), 1018 (w), 919 (w), 817 (m), 728 (s), 627 (w), 564 (w) cm-1; MS m/z 624, 609(65.18), 533(92.56), 519(28.45); Anal. Calcd for C35H36N4O7: C, 69.39; H, 5.70; N, 9.23; O, 11.93. Found: C, 67.93; H, 5.79; N, 9.95; O, 10.87.

Synthesis of 6d structure

For instance here is presented the method of preparing (6d) poly (amide-imides). In a round-bottomed flask (25 mL) equipped with drying tube, 0.04 g (2.07×10-4mol) diamine added to 0.50 mL of NMP. After complete salvation of diamine, this solution cooled until (-5 ºC) and through stirring 0.10 g of 3f was added (2.07×10-4mol). After reactants solvation, 0.03 mL of (TMSCl) added and this reaction for 4 hours was stirring at the nitrogen atmosphere. System temperature reduced to room temperature an was stirring for 5 hours. Obtained viscous solution added to 40.00 mL of methanol and polymer sediment after purification was dried under the vacuum condition at 80 ºC for (1e) hours. Yield of reaction was 90% and resulting polymer was 0.114 g.

to give 6d (0.114 g, 90%); A yellow dark compound; IR (KBr): 3300 (m, br), 2954 (s), 1772 (s), 1723 (s, br), 1595 (s), 1525 (s), 1464 (m), 1406 (s, sh), 1381 (s), 1344 (s), 1316 (s, sh), 1247 (m), 1186 (m), 1154 (s), 1075 (s), 1106 (s), 1079 (s), 1010 (w), 907 (w), 838 (m), 720 (s), 680 (m), 628 (m), 559 (m) cm-1.1H-NMR (DMSO-d6, TMS, 500 MHz)d: 0.83 (s, br, 3H), 1.02 (s, br, 3H), 1.50 (m, 2H), 2.69 (m, 1H), 3.85-4.08 (m, 1H, J = 7.56 Hz), 4.66-4.68 (d, 1H, J = 7.90 Hz), 6.90-6.92 (d, 1H, J = 7.60 Hz), 7.51-7.54 (d, 1H, J = 7.85 Hz), 8.29 (s, 1H), 10.12 (s, NH), 10.82-11.05 (s, 1H) ppm; MS m/z 626, 611(99.12), 535(49.35), 521(74.36); Anal. Calcd for C34H34N4O8: C, 67.09; H, 5.30; N, 9.20; O, 15.87.Found: C, 67.14; H, 5.66; N, 9.97; O, 14.77..

Result and Discussion

26 new poly (amide-imides) which have optical active were synthesized in solution phase with direct condensation polymerization. For more information refer to primary materials, product and yield with speed of mechanism (Table 1 to 4). For synthesizing of related diacids of di methyl formamide solvent acetic acid and acetic acid pyridine mixture that acetic acid was selected because of high yield and increasing of reaction speed. New monomers with aromatic di amines with direct condensation polymerization in solution phase were reacted with two kinds of different conditions: graduated heat processing and quick heat processing and at the end, new optical active poly (amide-imides) obtained with high yield. Through one minute with quick heat processing, in the reflux state, two monomers and active reagent were reacted and in comparison with graduated heat processing, under the same conditions, are obtained polymers with higher viscosity. NMP/CaCl2was used in this method because of high polarization and it reduces hydrogen bond between polymeric chains and causing high molecular weight for polymerization. One of the advantages of direct method is that the reaction needs to lower levels and monomers have stability. But disadvantage of that it is very expensive for reagents and in the industrial measurement is not economically. Necessary conditions for synthesis of these polymers are as follow: presence of TMSCl low temperature and high temperature in DMAC and NMP solvents. Using of TMSCl lead to formation of polymers with higher yield. Another advantage of this mechanism is that reducing time for synthesis of compounds. Reaction of amine with diacyl chloride is a famous method for synthesis of poly amides in the industrial measurement.

Conclusion

Analysis of mentioned reactions lead us to following out comes:

From salvation view, synthetic polymers, as are show in tables related to polymers, all of polymers in polarized aprotic solvents are solvated.

Poly(amide-imides)s in comparison with other polymers have higher heat stability about (300 ºC) and this parameter can introduce these compounds as an important material in heat- insulations.

Direct condensation polymerization was used and lead to produce of polymers with higher molecular weight in optimized conditions and consequently at the least time mentioned compounds with highest output have synthesized.

All of the synthetic compounds have polymerization potentiality and have active optical active and they are derivations of active poly(imide-amide)s.

Obtained results showed that in condensation polymerization, reactants can react in neutral environments and produce polymer and side products. For deleting of acid side products must use of acid acceptors.

Acknowledgements

- P.W. Morgan, S.L. Kwolek, J.Polym. Sci, 62: 33 (1962).

- P.W. Morgan, J.Polym. Sci,C4: 1075 (1964).

- S.L. Kwolek, P.W. Morgan, J.Polym. Sci, A2: 2693 (1964).

- W.E. Hanford, J.C. Sauer, Organic Reaction, Vol. III, Wiley, New York, (1964).

- N.O.V. Sonntag, Chem. Rev, 52: 237 (1953).

- A.H. Frazer, J.C. Shivers, J. Am. Chem. Soc, 77: 5595 (1955).

- J.A. Campbell, J. Org. Chem,22: 1259 (1957).

- W.B. Wright, H.J. Brabander, J. Org. Chem, 26: 4057 (1961).

- N. Yamazaki, M. Matsumoto, F. Higashi, J. Polym. Sci., Polym. Chem. Ed, 13: 1373 (1975).

- N. Yamazaki, M. Matsumoto, F. Higashi, J. Polym. Sci., Polym. Chem. Ed, 13: 1381 (1975).

- F. Higashi, S. Ogata, Y. Aoki, J. Polym. Sci., Polym. Chem. Ed, 20: 2081 (1982).

- S.M. Aharoni, W.B. Hammond, J.S. Szobota, J. Polym. Sci., Polym. Chem. Ed, 22: 2579 (1984).

- F. Higashi, A. Hoshio, J. Kiyoshige, J. Polym. Sci., Polym. Chem. Ed,21: 3241 (1983).

- P.W. Morgan, S.L. Kwolek, J.Polym. Sci, A2: 181 (1964).

- P.W. Morgan, S.L. Kwolek, J.Polym. Sci, A2: 209 (1964).

- K.H. Park, S. Watanabe, M. Kakimoto, Y. Imai, Polym.J, 25: 209 (1993).

- A. Pourjavadi, M.R. Zamanlou, M.J. Zohurian-mehr, Die Angew.Macromol.Chem, 269: 54 (1999).

- M.C. Patel, A.D. Shah, Oriental journal of chemistry, 19: (2002).

- B.F. Adeosun and P.A. Oyewusi, Oriental journal of chemistry, 22: 38808 (2006).

- M. Saraf, G. Garg, S. Saraf, Oriental journal of chemistry, 21: 38687 (2005).

- F. Akutsu, M. Inoki, K. Araki, Y. Kasashima, Polym. J, 29: 529 (1997).

- S. Maiti, A. Ray, J. Polym. Sci., Polym.Chem, 21: 999 (1983).

- C.P. Yang, J. Polym. Sci., Polym.Chem, 17: 3255 (1979).

- K.H. Becker, H.W. Schmidt, Macromolecules, 25: 6784 (1992).

- N. Yamazaki, F. Higashi, J. Kawabata, J. Polym. Sci., Polym.Chem, 12: 2148 (1974).

- M. Kakimoto, R. Akiyama, Y.S. Neg, Y. Imai, J. Polym. Sci., Polym.Chem, 26: 99 (1988).

This work is licensed under a Creative Commons Attribution 4.0 International License.