Chemo-and Regioselective Bromination of Aromatic Compounds in the Presence of γ-picolinium Bromochromate (γ-PBC) /CH3CN

N. O. Mahmoodi1 , M. R. Yazdanbakhsh and F. Hassanzadeh

Department of Chemistry, Faculty of Science, University of Guilan, Rasht (Iran).

inium bromochromate in either CH3 COOH or CH3 CN is reported. The results obtained revealed excellent yields of monobromo compounds at para- position under thermal condition especially in methyl cyanide.

KEYWORDS:regioselective; oxidative; bromination; γ-picolinium bromochromate (γ-PBC); thermal condition

Download this article as:| Copy the following to cite this article: Mahmoodi N. O, Yazdanbakhsh M. R, Hassanzadeh F. Chemo-and Regioselective Bromination of Aromatic Compounds in the Presence of γ-picolinium Bromochromate (γ-PBC) /CH3CN. Orient J Chem 2011;27(2). |

| Copy the following to cite this URL: Mahmoodi N. O, Yazdanbakhsh M. R, Hassanzadeh F. Chemo-and Regioselective Bromination of Aromatic Compounds in the Presence of γ-picolinium Bromochromate (γ-PBC) /CH3CN. Available from: http://www.orientjchem.org/?p=11685 |

Introduction

Brominated aromatic compounds are valuable intermediates in organic synthesis and they have been used widely in industrially important products and biologically active substrates as antitumor, antifungal, antibacterial, antiviral compounds,1,2 and also found in pharmaceutically and biologically important compounds.3 Until now various methods have been developed for the bromination of aromatic compounds using a variety of brominating agents under various conditions.4 Development of modern coupling reactions such as the Still-Kumada, Heck and Sonogashira reactions has greatly increased the demand for brominated aromatic compounds.5

Direct treatment of aromatic compounds with molecular bromine normally results in a mixture of mono-, di-, and polysubstituted products.6 In addition direct bromination of activated aromatic compounds by bromine generates hydrogen bromide, which is corrosive, toxic and pollutes the environment.7-9

To overcome these difficulties, numerous methods have been proposed to increase the selectivity and also the yields of the desired para-products.10-12

Results and Discussion

There are many different methods available to brominating of aromatic compounds. Some of them have regioselective with good yields.13-14

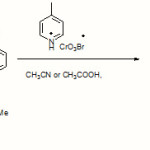

In order to this type of regioselective bromination of aromatic compounds,here we report the use of γ-picolinium bromochromate as the source of bromine and oxidizing agent in either CH3COOH or CH3CN as solvents for the bromination of a number of activated aromatic compounds. (Scheme 1)

The reagent was conveniently prepared by the reaction of equimolar quantities of chromium trioxide, 47% aqueous hydrobromic acid and γ-picoline (γ-PBC) in 88% yield.

γ-PBC is a dark brown solid, non-hygroscopic, air-stable and moderately light sensitive, which during preparation and storage should be protected from the light.

|

Scheme 1 Click here to View scheme |

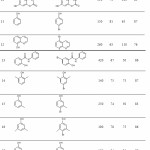

The chemo- and regioselective brominating ability of this reagent in the suitable polar solvents and under thermal condition for several aromatic compounds was investigated. The results are shown in Table 1.

|

Tabe 1: Bromination of aromatic compounds with γ-PBC in CH3COOH and CH3CN under thermal condition. |

However, in the other efforts when we utilized a CH3CN instead of CH3COOH surprisingly the yield of all reactions improved up to ~ 30-33% and the reaction times was also considerably reduced. The reactions were preformed under reflux condition at 90 ˚C. As shown in Table 1, the methoxy benzenes were successfully reacted to afford the desired monobrominated products (Table 1, entries 1-5). N,N-dimethylaniline and N,N-diethylaniline gave mainly the para isomer as the major product (Table 1, entries 6 and 7). 1-Naphthol was also brominated in good yield (Table 1, entry 8). Acetanilide and 7-hydroxycumarin gave the brominated compounds in good yields (Table 1, entries 9 and 10). Some other aromatic compounds such as phenol, 8-hydroxyquinoline, salicylanilide, 2,6-DMP, m-cresol, resorcinol, 3,5-xylenol and 3-hydroxy-5-methylphenol were quantitatively converted to the para-brominated products with respect to the hydroxyl groups (Table 1, entries 11-18). 2-Bromoethoxybenzene was quantitatively reacted to give the corresponding para-brominated product (Table 1, entry 19). When the amine substituent is available in the para-position of the aromatic ring and the substituents are huge, no reaction was observed and the starting material was recovered unreacted after 10h refluxing in either CH3COOH and /or CH3CN (Table 1, entries 20 and 21).

Conculusion

In brief, we have developed a simple reagent system, γ-PBC as an efficient brominating agent for activated aromatic compounds at thermal condition. A notable advantages of this system lies in its ability to chemoselectively brominates of para vs. ortho positions, simple workup, good chemo-, and regioselectivity and the products readily available under CH3CN as a solvent in short time and with high to excellent yields that make this method as a useful method.

Experimental

All products were identified by comparison of their spectral and physical data with those of the known samples.15 Melting points were measured on a Mettler Fp5 apparatus and are uncorrected. The IR spectra were recorded on a Shimadzu IR-470 spectrophotometer. The ¹H NMR spectra were recorded on a Bruker 500 MHz instrument using solvent as internal standard (CDCl3 at 7.31 ppm). Solvents were purchased from the Merck chemical company.

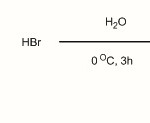

General procedure for the preparation of γ-picolinium bromochromate

To a cold (0 ˚C) stirred solution of chromium trioxide (6.0 g, 60.0 mmol) in water (7.5 ml), 47% aqueous hydrobromic acid (6.9 g, 60.0 mmol) was slowly added. To this solution γ-picoline (5.7 g, 60.0 mmol) was added dropwise in 15min, and stirring was continued at 0 ˚C for 3 hours. The reaction mixture was evaporated at 60 ˚C under vacuum to produce a dark brown solid which was washed by diethyl ether and dried by vacuum pump to give γ-picolinium bromochromate (14.5 g, 52 mmol) in 88% yield. (Scheme 2)

Dark brown solid, Yield = 88%, m.p. 285 ˚C, 1H NMR (CDCl3, 500 MHz) δ (ppm): 2.76 (s, 3H), 7.95 (d, 360. 2H, J = 6.12 Hz), 8.67 (d, 2H, J = 6.12 Hz); IR (KBr, ν/cm-1): 3400, 3050, 2900, 1605, 1495, 1040, 955, 760.

|

Scheme 2 Click here to View scheme |

General procedure for the bromination with γ-PBC in CH3CN/ CH3COOH under thermal condition

To a magnetically stirred suspension of γ-PBC (20.0 mmol) in CH3CN/ CH3COOH (25 ml) was added aromatic substrates (10.0 mmol) (Table 1) in portions during 5 min. The reaction mixture was heated at 90 ˚C for the desired reaction time (Table 1), and the progress of the reaction was monitored by TLC (petroleum ether / EtOAC: 2/1). After completion of the reaction which was evidenced from the change in color of the mixture to green, the reaction mixture was poured into water (100 ml) and extracted by (Et)2O (3 х 20 ml). The combined ethereal extract was dried over MgSO4. The organic phase was evaporated by vacuum pump and purified by column chromatography (petroleum ether / EtOAc: 4/1) to produce the brominated products (Table 1).

Spectral Data of the Selected Products

4-Bromoanisole (Entry 1, Table 1): Liquid. b.p. 215 oC, 1H NMR (CDCl3, 500 MHz) δ (ppm): 3.77 (s, 3H), 6.78 (d, 2H, J = 8.9 Hz), 7.37 (d, 2H, J = 8.9 Hz); IR (KBr, ν/cm-1): 3300, 2860, 1590, 1487, 1289, 1239, 1070, 1033.

4-Bromo-methoxynaphtalene (Entry 2, Table 1): Liquid. b.p. 146-147 oC, IR (KBr, ν/cm-1): 3350, 2930, 1590, 1475, 1120, 1040.

1-Bromo-2,3,4-trimethoxybenzene (Entry 3, Table 1): Viscous oil. M.p. 75-75 oC, 1H NMR (CDCl3, 500 MHz) δ (ppm): 3.84 (s, 3H), 3.88 (s, 3H), 3.90 (s, 3H), 6.58 (d, 1H, J = 9.0 Hz), 7.20 (d, 1H, J = 9.0 Hz); IR (KBr, ν/cm-1): 3020, 2870, 1580, 1220, 1070.

1-Bromo-2,4,5-trimethoxybenzene (Entry 4, Table 1): Liquid. b.p. 263 oC, 1H NMR (CDCl3, 500 MHz) δ (ppm): 3.81 (s,3H), 3.84 (s, 3H), 3.86 (s, 3H), 6.54 (s, 1H), 7.01 (s, 1H).

3-Methoxy-4-bromoanisole (Entry 5, Table 1): Liquid. b.p. 246 oC, 1H NMR (CDCl3, 500 MHz) δ (ppm): 3.82 (s, 3H), 3.89 (s, 3H), 6.42 (d, 1H, J = 2.2 Hz), 6.45 (d, 1H, J = 2.2 Hz), 7.65 (d, 1H, J = 8.8 Hz).

N,N-Dimethyl-4-bromoaniline (Entry 6, Table 1): Viscous oil. M.p. 54-55 oC, 1H NMR (CDCl3, 500 MHz) δ (ppm): 2.98 (s, 6H), 6.66 (d, 2H, J = 8.9 Hz), 7.37 (d, 2H, J = 8.9 Hz); IR (KBr, ν/cm-1): 3030, 2960, 1590, 1450, 1340, 1075.

N,N-Diethyl-4-bromoaniline (Entry 7, Table 1): Viscous oil. M.p. 67-68 oC, 1H NMR (CDCl3, 500 MHz) δ (ppm): 1.14 (t, 6H, J = 7.1 Hz), 3.31 (q, 4H, J = 7.1 Hz), 6.54 (d, 2H, J = 8.8 Hz), 7.65 (d, 2H, J = 8.9 Hz); IR (KBr, ν/cm-1): 3100, 2930, 1589, 1489, 1360, 1070.

4-Bromo-acetanilide (Entry 9, Table 1): Solid. M.p. 165-167 oC, 1H NMR (CDCl3, 500 MHz) δ (ppm): 2.04 (s, 3H), 7.47 (d, 2H, J = 8.9 Hz), 7.56 (d, 2H, J = 8.9 Hz), 10.07 (s, 1H); IR (KBr, ν/cm-1): 3300, 2900, 1640, 1590, 1483, 1070.

4-Bromophenol (Entry 11, Table 1): Solid. M.P. 61-63 oC, 1H NMR (CDCl3, 500 MHz) δ (ppm): 5.45 (s, 1H), 6.77 (d, 2H, J = 8.9 Hz), 7.38 (d, 2H, J = 8.9 Hz); IR (KBr, ν/cm-1): 3350, 2960, 1530, 1490, 1250, 1070.

4-Bromoresorcinol (Entry 17, Table 1): Solid. M.p 100-101 oC. 1H NMR (CDCl3, 500 MHz) δ (ppm): 6.36 (d, 1H, J = 2.7 Hz), 6.56 (d, 1H, J = 2.7 Hz), 7.25 (d, 1H, J = 8.2 Hz).

Acknowledgements

We are thankful to the Research council of University of Guilan for partial support of this work.

References

- Roy, S. C.; Gunin, C.; Rana, K. K. and G. Maiti., Tetrahedron Lett., 42: 6941(2001).

- Butler, A. and Walker, J. V., Chem. Rev., 93: 1937(1993).

- Tajik, H.; Shirini, F.; Hassan-Zadeh, P. and Rafiee Rashtabadi, H., Synth. Commun., 35: 1947(2005).

- Ganim, J. M. and Sheldon, R. A., Tetrahedron Lett., 46: 4465(2005).

- Gupta, N.; Kad, G. L.; Singh, V. and Singh, J., Synth. Commun., 37: 3421(2007).

- Tajik, H.; Mohammadpoor-Baltork, I. and Albadi, J., Synth. Commun., 37: 323(2007).

- Morrel, D., Catalysis of organic reactions, Vol. I, Marcel Dekker, New York, 381(2002).

- Bekaert, A.; Provot, O.; Rasolojaona, O.; Mouâd Alami, M. and Brion, J. D. Tetrahedron Lett., 46: 4187(2005).

- Park, M. Y.; Yang, S. G.; Jadhav, V. and Kim,Y. H., Tetrahedron Lett., 45: 4887(2004).

- Chen, Q. H. and Wang, F. P., Chin. Chem. Lett., 12: 421(2001).

- Ghiaci, M. and Asghari, J., Bull. Chem. Soc. Jpn., 74: 1151(2001).

- Wang, S. -T.; Hwang, C. -C. and Mou, C. -Y., Appl. Catal. B., 63: 1(2006).

- Tajik, H.; Mohammadpoor-Baltork, I.; Hassanzadeh, P. and Rafiee Rashtaabadi, H., Russ. J. Org. Chem., 43: 1282(2007).

- Tajik, H.; Mohammadpoor-Baltork, I. and Rafiee Rasht-Abadi, H. Synth. Commun., 34: 3579(2004).

- Weast, R. C., CRC Handbook of Chemistry and Physics, Vol. I, CRC Press, Boca Raton, FL, 117-136(1977).

This work is licensed under a Creative Commons Attribution 4.0 International License.