Synthesis of novel disazo dyes and an investigation of their use in the textile industry

J. O. Otutu1, E. Osabohien1 and E. M. Efurhievwe2

¹Department of Chemistry, Faculty of Science, Delta State University, PMB 1, Abraka, Delta State (Nigeria). ²Nigeria National Petroleum Company, Petroleum Product and Quality Control Laboratory, Ekpan, Warri (Nigeria).

Article Received on :

Article Accepted on :

Article Published : 01 Mar 2010

A series of nitrothiazole (heterocyclic) disazo dyes has been synthesised and their fastness properties on polyester and nylon fibres were investigated. 2-chloroaniline (carbocyclic) disazo dye analogs were also synthesized in order to compare fastness properties. The nitrothiazole disazo dye derivatives absorbed maximally at higher wavelengths but they are generally, tinctorially as strong as the 2-chloroaniline analogs. Also, the nitrothiazole disazo dyes exhibited higher light fastness on polyester substrate than on nylon. However, all the synthesized dyes showed excellent wash, and sublimation fastness on polyester and nylon substrates. The dyes were characterized by IR, uv-visible and 1 HNMR analyses.

KEYWORDS:Heterocyclic dyes; polyester; thermal properties and nylon

Download this article as:| Copy the following to cite this article: Otutu J. O, Osabohien E, Efurhievwe E. M. Synthesis of novel disazo dyes and an investigation of their use in the textile industry. Orient J Chem 2010;26(1). |

| Copy the following to cite this URL: Otutu J. O, Osabohien E, Efurhievwe E. M. Synthesis of novel disazo dyes and an investigation of their use in the textile industry. Available from: http://www.orientjchem.org/?p=11500 |

Introduction

The use of heterocyclic coupling components and diazo components in the synthesis of azo disperse dyes is well established and the resultant dyes exhibit good tintorial strength and brighter dyeing than those derived from aniline based components. For instance, Hallas et al, reported that the synthesis of azo dyes derived from 2-aminofhiophene derivatives and their application on polyester fibres gave excellent results1,2. On the other hand, the use of amino-substituted thiazoles such as benzothiazoles, being very electronegative diazo components produce pronounced bathochromic shift when compared to the corresponding benzoid compounds3,4,5,6.

Although, many patents and papers described the synthesis and dyeing properties of monoazo dyes7,8,9,10, very few comparable investigations have been made with disazo dyes containing heterocyclic and carbocylic components11,12. In this present study, the syntheses of some novel disazo dyes derived from 2-amino-5-nitrothiazole as the heterocyclic diazo component and several aryloxy and arylamine compounds as coupling components is reported. Also, the fastness properties of the heterocyclic disazo disperse dyes and 2-chloroaniline disazo dye analogs have been investigated for comparative purposes.

Experimental

Materials

2-Amino-5-nitrothiazole, 3-aminophenol, 1,3- dihydroxybenzene, N-phenylnapthylamine, 1,4-dihydroxybenzene, 2-chloroaniline were obtained from. Aldrich chemical Co (USA) and Fluka chemical Co (Germany) and used without further purification.

Chemical and instrumental analysis

The structures of the novel compounds were confirmed by proton nuclear magnetic resonance (1H NMR) spectroscopic and infrared (IR) analyses. 1H NMR spectra were recorded on a mercury 200 BB MHz spectrometer equipped with an oxford wide Bore Magnet, sun 3/160 based computer with an array processor and GE Omega 6.0 software. Chemical shifts are given in d values (ppm) with tetramathylsilane (TMS) as internal reference and deuterated chloroform as solvent.

Melting points were determined using Thumbnail melting point apparatus and are uncorrected. The UV-visible spectra were measured in 1 cm quartz cells on a spectrophotometer (Genesys IOS VL. 200).

Fourier transform infrared (FTIR) spectra were recorded on a Nicolet Averser 330 series spectrophotometer. Dye purity was assessed by thin Layer chromatography (TLC) using Whatman 250 m silica gel 60 AMK 6F plates as the stationary phase and ether/acetone (5:1 by volume) mixture as developing solvent. Characterization data are shown in Tables 1 and 2.

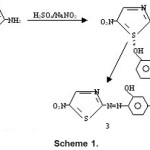

Synthesis of intermediates (Schemes 1, and 3).

2-Amino-5-nitrothiazole (15 g, 0.103 mole) was dissolved in a mixture of 66 g conc. H2SO4 and 33 g ice at 25oc. A solution of 7.5 g, sodium nitrite (0.109 mole) dissolved in 45 g concentrated sulphiric acid was added dropwise to the amino nitrothiazole solution at -10oC to 0oC with stirring. After 30 min of stirring at -10oC to 0oC, the resulting diazonium salt was slowly added to the cooled solution of 11.3 g of 3-Aminophenol (0.109 mole) dissolved in 20 ml (4.14 g, 0.104 mole) sodium hydroxide at 0-5oC with vigorous stirring for 5 min. The mixture was further stirred for 1h and the resultant product obtained was collected by filtration and washed with water. The crude product was then recrystallized from hot ethanoic acid to give 18.59 g (68% yield) as brown crystals of 4-nitrothiazole azo-41-amino-2-hydroxybenzene.

Synthesis of dyes

Method 1: Synthesis of 4-Nitrothiazoleazo-2-hydroxyphenyl azo-2,41-dihydroxybenzene

4 – Nitrothiazoleazo – 41 – amino – 2 – hydroxybenzene (4.0 g, 0.015 mole) was diazotized in 6.0 ml of concentrated sulphuric aicd and 22 g ice mixture with a solution of 3.5 g sodium nitrate (0.0507 mole) dissolved in 40 g concentrated sulphiric acid. Excess nitrous acid was destroyed using urea (0.15 g, 0.003 mole) solution. The coupling component 1,3-dihydroxybenzene (1.7 g, 0.154 mole) dissolved in 20 ml of 2 molar sodium hydroxide solution was cooled to 0-5oc. The diazo solution prepared above was slowly added into the coupler solution with vigorous stirring for 18 min at 0.3oC. Stirring was continued further for 2h and the precipitated product was filtered off, washed with water and dried. The crude product was then recrystallized from hot acetic acid to give dye 5a, 4-n i t r o t h i a z o l e – 2 – h y d r o x y p h e n y l a z o – 1 , 3 – dihydroxybenzene as brown solid. (2.0 g, 68.7%). This procedure was also used to synthesise dye 5b.

|

Scheme 1 Click here to View scheme |

|

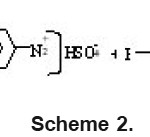

Scheme 2 Click here to View scheme |

Method 2: Synthesis of 4-Nitrothiazoleazo-2-hydroxyphenyl azo-N-phenylnaphthylamine

4 – Nitrothiazoleazo – 41 – amino – 2 – hydroxybenzene (4.0 g, 015 mole) was suspended in 50 ml water and 6.0 ml concentrated sulphuric acid was added to the suspension a little at a time with stirring. The resultant mixture was then cooled to 0-5oC and a solution of 3.5 g. Sodium nitrite (0.0507 mole) dissolved in 45 g concentrated acid was added dropwise to the above mixture at -10oC to 0oC with stirring. After stirring for 30 min. at -10oC to 0oC, the resulting diazonium salt solution was slowly added to the cooled solution of 3.4 g (0.0155 mole) of N-phenylnaphthylamine dissolved in 8 ml acetic acid with vigorous stirring for 10 min. The mixture was further stirred for 2 h and the crude product was collected by filtration washed with water and dried. The crude product was purified by recrystallization from hot ethanol-methanol mixture to give compound 5c in 5.9 g (56%) yield as a brown solid.

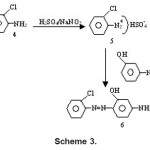

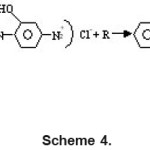

In other to synthesise 2-chloroaniline dye analogs, the same procedure was repeated except that in this series, hydrochloric acid was used to generate the nitrous acid for the diazotization process, since a chloroaniline is the diazo component.

Dye applications

Dye dispersions

Prior to dyebath preparation, each dye was dissolved in N,N-dimethylformatmide (DMF) and added slowly to a flask containing a solution of dispersing agent (Ligninsulfonates-sulfite cellulose Liquors) and made up to 100 ml mark.

|

Scheme 3 Click here to View scheme |

|

Scheme 4 Click here to View scheme |

Application of dyes 5a-c and dyes 8a-c on polyester fabric

Polyester fabric was dyed at 130oC for 1.5 h using a Mathis Labomat dyeing machine with a 3oC/ min. temperature gradient, and a dyebath containing 1% of weight of fibre (owf) and 2% owf dispersing agent (Ligninsulfonates-sulfite cellulose Liquors) with a liquor ratio of 20:1. After allowing the dyeing vessel to cool below 100oC, the fabric was removed from the hot dyebath, rinsed with cold water to remove unfixed dye and air dried. Dyed fabrics were reduction cleared in an aqueous solution of 2 g/L sodium hydroxide and 2 g/L sodium hydrosulphite at 80oC for 30 min. The dyebath preparation and dyeing procedure were as described in literature13.

Application of dyes 5a – c and dyes 8a – c on nylon 66 fabric

Nylon fabrics were dyed at 90oC for 1 h using an Ahiba Texomat dyeing machine with a 3oC/ min temperature gradient, and a dyebath containing 1% owf dye and 2% owf dispersing agent (Ligninsulfonates-sulfite cellulose Liquors) based on the fabric weight. The liquor ratio was 60: 1 and the pH was 3 (using 1% acetic acid). The dyed fabric was removed from the hot dyebath, rinsed with cold water and air dried14.

Fastness testing

Light fastness

Light fastness was evaluated by exposing the fabrics to the xenon lamp of an Atlas 3 Sun Weather-Ometer, according to the conditions of AATCC Test Method 16E-1993[15]. Test conditions were: black panel temperature, 63oC, dry bulb temperature, 43oC; relative humidity, 30%; duration of test 24 h. The resultant fabrics were rated against standard blue wool samples (grade 1-8).

Wash fastness Test

Wash fastness to laundering was evaluated by using a linitest washwheel machine, according to the conditions of ISO washing test 3. The composite samples of polyester and nylon fabrics were treated respectively with a mixture of 0.2% soap solution and 2 g/L (0.618 mole) sodium carbonate liquor ratio 50:1 for 30 min. at 60oC. The change in colour of the fabric and the degree of staining of the two adjacent undyed fabrics were evaluated using grey scales16.

Sublimation fastness

Sublimation test was determined according to ISO 105-POI, 1993 protocol17. The dyed fabrics were treated in a sublimation testing machine at 177oC for 30 s and then rated against the standard grey scales.

Rubbing fastness

The rubbing test was carried out according to ISO 105-X12; 200118. The tested specimens were assessed according to the grey scales.

Results and Discussion

Dye synthesis

Scheme 1 shows that the first step of the synthesis involves the preparation of the intermediate diazo component. In this regard, the starting material, 2-amino-5-nitrothiazole was diazotized and coupled with 3-aminophenol according to the published methods19,20. The yield of the dye intermediate (3) was moderate (69%). In the second step of the reaction sequence, the dye inter mediate (3) was diazotized and the diazonium salt was coupled with aryloxy and arylamine compounds to give disperse dyes (Scheme 2). The prepared heterocyclic dyes were characterized using IR, uv-visible and 1H NMR analyses as shown in Tables 1 and 2.

Thermal properties

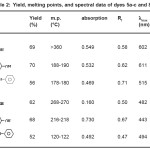

All the prepared dyes, except, 5c and 8c exhibited high thermal stability (Table 2). Although it would be unwise to attempt to explain in detail their relative values because of the complex dependence of the melting points on a number of factors, a few general trends can be accounted for. The dyes prepared from low melting coupling compounds (such as in dyes 5c and 8c which gave melting points 178-180 and 120-122 respectively) tended to have low thermal stability compared to the others. Also, it is presumed that, the more polar dye which contain more powerful electron-withdrawing group tend to have better thermal stability; the nitrothiazole disazo dye derivatives and the 2-chloroaniline analogs which do not contain arylamine as coupling component generally exhibited higher thermal properties.

|

Table 1: IR and 1H NMR data for dyes 5a-c and 8a-c Click here to View table |

|

Table 2: Yield, melting points, and spectral data of dyes 5a-c and 8a-c Click here to View table |

Absorption spectra

The electronic spectral data (Table 2) of the dyes showed that the nitrothiazole derived dyes gave higher λmax than the 2-chloroaniline derivatives. The reason for this may be attributed to the presence of the nitro group and also the –OH group(s) which ensure maximum p-electron overlap as a result of intramolecular hydrogen bond formation with the azo linkage. Also, the nitrothlazole derived disazo dyes gave brighter dyes than their 2-chloroaniline counterparts. This corroborates with the recent work done on heterocyclic disazo dyes8.

The 1R spectral data gave absorption frequencies for –OH and C-O stretching vibrations for all the dyes. NH stretching vibrations for dyes 5c and 8c, NO2 symmetric and antisymmetric stretching vibrations for dyes (5a-c). These absorption frequencies quite agree with those reported in literatures21,22.

Fastness test

Light fastness

The light fastness test results (Table 3) showed that the dyes derived from the nitrothiazole diazo component gave good light fastness on polyester (PET) fabric with a rating of 6 compared with those of 2-chloroaniline derivatives with ratings of 4 to 5 on PET. The high light fastness of the nitrothiazole disazo dyes on PET could be due to the presence of the nitro group in the dye structure. The same dyes, however, gave light fastness ratings of 4 on the nylon substrate. The low light fastness of the dyes on nylon fibre is due to that fact that it has higher moisture regain than PET23. Thus, the rate of photofading on PET may be retarded because access of water vapour to the dye particle is restricted.

Table 3: Fastness properties of dyes 5a-c and 8a-c (1% owf) on PET and nylon

| Dye | Light | Wash | Sublimation | Rubbing | Colour on fabric | |||||||

| PET | nylon | PET | nylon | PET | nylon | PET | nylon | PET | nylon | |||

| Dry | Wet | Dry | Wet | |||||||||

| 5a | 6 | 4 | 5 | 5 | 5 | 5 | 04-May | 4 | 04-May | 04-May | Pink | Pink |

| 5b | 6 | 4 | 5 | 5 | 5 | 5 | 04-May | 04-May | 04-May | 04-May | Pink | Pink |

| 5c | 6 | 4 | 5 | 5 | 5 | 5 | 04-May | 04-May | 04-May | 4 | Orange | Orange |

| 8a | 5 | 4 | 5 | 5 | 5 | 5 | 03-Apr | 03-Apr | 03-Apr | 4 | Orange | Orange |

| 8b | 5 | 5 | 5 | 5 | 5 | 5 | 03-Apr | 04-May | 4 | 03-Apr | Orange | Orange |

| 8c | 5 | 4 | 5 | 5 | 5 | 04-May | 03-Apr | 03-Apr | 03-Apr | 03-Apr | Brown | Brown |

Wash fastness

The wash fastness test results (Table 2) showed no change in colour and staining of adjacent undyed fabrics for all the dyes on PET and nylon fabrics except dye 8c of the 2-chloroamline derivatives. The excellent wash fastness is attributed to the high molecular weight of the dyes.

Sublimation fastness

The results of the sublimation fastness test showed that all the dyes are quite stable to heat. Thus, the presence of the polar groups such as –Cl and –NO2 in the diazo components of the dyes tend to have given them enough stability to sublimation.

Rubbing fastness

The rubbing fastness test results (Table showed that the nitrothiazole derived dyes gave moderate to good ratings in both change in colour and staining of adjacent undyed fabrics on PET and nylon fabrics. However, the rubbing fastness ratings of the 2-chloroaniline disazo dyes (8a-c) are lower than those of the nitrothiazole disazo dyes.

Conclusions

A series of nitrothiazole disazo disperse dyes were prepared from the coupling reactions between carbocyclic couplers and prepared 4-nitrothiazoleazo-41-amino-2-hydroxybenzene, and their fastness properties were investigated.

References

- F. Karci, Jour. Soc. Dyers colourists. (J.S.D.C.), 121: 275-280, (2005).

- G. Hallas and A.D. Towns. Dyes and pigm. 31: 133, (1996).

- G. Hallas and A.H.M. Renfrew. Jour. Soc. Dyers Colourists (J.S.D.C.) 112: 207-208 (1996).

- L. Shuttleworth, and M.A. Weaver. The chemistry and application of dyes. New York. Plenum Press, (1970).

- Mitsubishi chemical industries Co. Ltd, Jap. Patent 1980, 55005a66, Chem. Abstr. 92: 199 750x. (1980).

- H. Tappe; K. Roth; A.G. Cassella; Ger. Offen 3, 036578; Chem. Abstr., 97: 571167z. (1982).

- M.A. Weaver; H.S. Priagen; Eastman Kodak Co. US Patent 1972, 36: 385, Chem. Abstr. 76, 15583k. (1972).

- P. Gregory in: the chemistry and application of dyes (Eds, D.R. Warring and G. Hallas). New York. Plenum Press; (1970).

- J.B. Gosei; Gijupsu kenktu Kumaiai. Jap. Patent 1983, 59215355; Chem. Abstr. 102: 186655 (1983).

- J. Straley; D. Wattance; Eastman Kodak Co. US patent 1965, 3206452; Chem. Abstr., 63, 1831h (1965).

- W.M.F. Fabian and S. Timofei, THEOCHEM, 362 155 (1996).

- M. Matsni; Y. Kamino, M. Hayashi, K. Funabiki, K. Shibata, H. Muramatsu, Y. Abe and M. Kaneko, Liq. Cryst. 25: 235, (1998).

- C.H. Giles, A Laboratory Course in dyeing. Bradford. Soc. Dyers Colourists (S.D.C.), (1974).

- P. Suwankuji; H.S. Freeman and D. zhao. Colour Technol. 50: 220-225 (2004).

- Technical Manual. American Association Textile Chemists and Colourists (AATCC) North Carolina, (1993).

- J.O. Otutu, E.K. Ossai and E.O. Jatto. J. Chem. Soc. Nig. 32: 81-90 (2007).

- ISO 105-POI. Textile test for colour fastness to dry heating excluding pressing (Geneva ISO, 1993).

- ISO 105-X12. Textile Test for colour fastness to rubbing part X12 (Geneva ISO, 2001).

- J.B. Dickey; E.B. Towne; Eastman Kodak Co. US patent 1955, 2659719; Chem. Abstr., 49: 1335 (1955).

- J.O.Otutu; D. Okoro and E.K. Ossai. J. Appl. Sci. Pak. 8: 334-339, (2008).

- Y.B. Paula. Organic chemistry. New York. Prentice-Haul Inc., (1995).

- A.D. Cross and R.J. Allen. Introduction to practical infrared spectroscopy, 3rd edn. London Butterworth and Co. Ltd., (1966).

- K. Venkataraman. The chemistry of synthetic dyes 5th edn. Vol. III. New York. Wiley Interscience Pub. Co., (1977).

This work is licensed under a Creative Commons Attribution 4.0 International License.