Rheological Models for Behavior of Sesame (Sesamum indicum) oil

University of Bucharest, Faculty of Chemistry, Department of Physical Chemistry, 4-12 Elisabeta Blvd, 030018, Bucharest, Romania.

Corresponding Author E-mail: istanciu75@yahoo.com

DOI : http://dx.doi.org/10.13005/ojc/400120

Article Received on : 25 Dec 2023

Article Accepted on :

Article Published : 16 Feb 2024

Reviewed by: Dr. Rubalya Valantina

Second Review by: Dr. Neelaveni Thangavel

Final Approval by: Dr. Pounraj Thanasekaran

Sesame (Sesamum indicum) oil is the fatty matter obtained from sesame seeds, by cold pressing or hot pressing, followed by refining. The seeds must have a maximum moisture content of 7% and must be free of foreign bodies. After pressing, the oil is decanted and then filtered, through a natural cotton filter, thus ensuring the superior quality of the obtained oil. Sesame oil is the most resistant oil to oxidation and is stable at room temperature. The burning point is 177 degrees for cold pressed sesame oil.

KEYWORDS:Lubricant; Oil; Rheology; Sesame

Download this article as:| Copy the following to cite this article: Stanciu I. Rheological Models for Behavior of Sesame (Sesamum indicum) oil. Orient J Chem 2024;40(1). |

| Copy the following to cite this URL: Stanciu I. Rheological Models for Behavior of Sesame (Sesamum indicum) oil. Orient J Chem 2024;40(1). Available from: https://bit.ly/3T0vKXy |

Introduction

Sesame oil is a vegetable oil derived from sesame seeds. The Latin name of this heat-loving plant is Sesamum indicum. Sesame oil has been known for over seven thousand years. It is not difficult to guess that this valuable product has found its application in many branches of human life. This product is used in the food industry, canning, baking and confectionery, in Chinese, Indian, Japanese, Thai and Korean cuisine. It is also used in the perfume industry and for technical purposes 1-3.

Cold-pressed sesame oil is a traditional ingredient in Asian cuisine. It is added to pilaf, fish and seafood dishes, marinades and meat and vegetable dishes. Sesame is perfectly combined with soy sauce, honey, cakes and sweets. In the Romanian kitchen, oil found its application in the manufacture of bread, sweets, homemade cakes. Add seeds and oil in the preparation of pancakes and various sauces. Add a special flavor to simple dishes such as soups, cereals, mashed potatoes by adding just a few drops to the finished product. Since the oil has a high energy and nutritional value, it contains digestible fats and proteins, it is successfully used for food.

Sesame oil is the fatty matter obtained from sesame seeds, by cold pressing or hot pressing, followed by refining. The seeds must have a maximum moisture content of 7% and must be free of foreign bodies. Sesame oil obtained by cold pressing has a light yellow color, is of high quality, very stable, with a very fine taste, used in food, in the industry of canned fish, margarine and pastry products. It is considered a superior vegetable oil and an important source of energy. It ranks second in nutritional value after olive oil.4-10. Sesame oil obtained by hot pressing has a dark color, unpleasant taste and smell, is of lower quality and is used in the manufacture of fine soaps, in the paper, indigo, dye industry, and after refining it can also be used in food.

Sesame oil is semi-drying. After refining it can be used in food.

The oil extracted with alcohol is used in pharmacy and in the insecticides, perfumes industry .

The freshly obtained oil, by cold pressing, is used for various pharmaceutical purposes (hemorrhagic conditions).

The cakes resulting from oil extraction are rich in proteins (25%), fatty substances (5-14%) and can also be used for the preparation of various pastries, or in fried form, directly for consumption. 11-15

Material and methods

The sesame oil that is the object of this study was obtained by cold pressing, it does not require external heat or extraction with organic solvents, being a simple and ecological method. Compared to the other extraction methods, it is less expensive and easier, obtaining a high quality oil, despite the lower yield. Sesame oil obtained by cold pressing has a light yellow color, is of high quality, very stable, with a very fine taste, used in food, in the industry of canned fish, margarine and pastry products and for various purposes pharmaceuticals.

Figure 1 shows the diagram of this rheometer Brookfield RVDV II I Ultra adapter at a temperature of 25 degrees Celsius.

|

Figure 1: Brookfield RVDV II I Ultra Rheometer. |

Results and discussion

Sesame oil was studied from a rheological point of view in the temperature range of 40 -100 °C because in the range of these temperatures the behavior in the engine can be observed and it is used as a biodegradable lubricant. In this sense, we graphically represented the shear speed as a function of the shear stress over this temperature range.

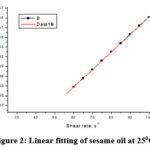

Figure 2 shows the linear fit of the experimental data for sesame oil.

|

Figure 2: Linear fitting of sesame oil at 250C. |

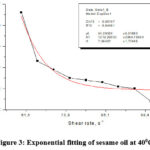

For the behavior in the engine, the representation of the dynamic viscosity as a function of the shear speed is also important, and as can be seen in the graph, it shows an exponential decrease in the dynamic viscosity with the shear speed due to the orientation of the oil molecules.

Figure 3 shows the exponential fitting of experimental data for sesame oil.

|

Figure 3: Exponential fitting of sesame oil at 400C. |

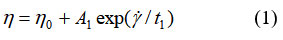

By exponentially fitting the experimental data of sesame oil, we obtained formula 1. The parameters found depend on the temperature and the type of oil studied.

The rheological model (1) obtained by fitting the experimental data for sesame oil.

where η0 = 54.29324 , A1= 1212.20033 and t1= 7.36437 R2= 0.94481

For the study of the behavior in the engine, it is also important to study the dependence of the dynamic viscosity on the shear stress. The curve obtained shows a decrease in dynamic viscosity with shear stress.

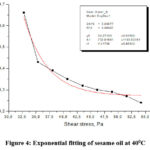

Figure 4 shows the exponential fitting of experimental data for sesame oil.

|

Figure 4: Exponential fitting of sesame oil at 400C |

By fitting the dynamic viscosity-shear stress curve we obtained formula 2. The obtained constants depend on the type of oil analyzed and the temperature.

The rheological model (2) obtained by fitting the experimental data for sesame oil.

where η0 = 54.27133, A1= 732.61681 and t1=4.31705 R2= 0.96407.

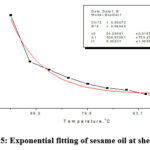

Figure 5 shows the exponential fitting of experimental data for sesame oil.

|

Figure 5: Exponential fitting of sesame oil at shear rate. |

By fitting the dynamic viscosity-temperature curve we obtained formula 3. The obtained constants depend on the type of oil analyzed, shear stress and shear rate.

The rheological model (3) obtained by fitting the experimental data for sesame oil. 11-15.

where η0 = 54.26981, A1= 508.63081 and t1= 8.30237 R2= 0.96645.

Conclusions

Sesame oil was studied in the temperature range 40-100 °C because it is important to know the behavior in the engine, therefore at high temperatures and consequently used as a biodegradable lubricant. In this article, we obtained by linear and exponential fitting of the experimental data three rheological models that describe the behavior of sesame oil. The oil has a non-Newtonian behavior at all temperatures and shear speeds.

References

- Budowski P., & Markley K.S., 1951, Chemical reviews, 48(1), 125-151.

CrossRef - Mohamed H.M.A., & Awatif I.I., 1998, Food chemistry, 62(3), 269-276.

CrossRef - Abou-Gharbia H.A., Shehata A.A.Y., & Shahidi F., 2000, Food research international, 33(5), 331-340.

CrossRef - Ji J., Liu Y., Shi L., Wang N., & Wang X., 2019, LWT, 101, 191-200.

CrossRef - Latif S., & Anwar F., 2011, Food chemistry, 125(2), 679-684.

CrossRef - Hsu E., & Parthasarathy S., 2017, Cureus, 9(7).

- Sankar D., Rao M.R., Sambandam G., & Pugalendi K.V., 2006, Journal of medicinal food, 9(3), 408-412.

CrossRef - Valacchi G., Lim Y., Belmonte G., Miracco C., Zanardi I., Bocci V., & Travagli, V., 2011, Wound Repair and Regeneration, 19(1), 107-115.

CrossRef - Zanardi I., Travagli V., Gabbrielli A., Chiasserini L., & Bocci V., 2008, Lipids, 43(9), 877-886.

CrossRef - Kikugawa K., Arai M., & Kurechi T., 1983, Journal of the American Oil Chemists’ Society, 60(8), 1528-1533.

CrossRef - Jayaraj P., Narasimhulu C.A., Rajagopalan S., Parthasarathy S., & Desikan R., 2020, Food & function, 11(2), 1198-1210.

CrossRef - Stanciu I., 2019, Journal of Science and Arts, 3(48), 703-708.

- Stanciu I., 2019, Journal of Science and Arts, 4(49), 938-988.

CrossRef - Stanciu I., 2011, Journal of Science and Arts, 1, 55-58.

- Stanciu I., 2018, Journal of Science and Arts, 18(2), 453-458.

This work is licensed under a Creative Commons Attribution 4.0 International License.