Achieving High Removal Efficiency and Membrane Sustainability in Pulp and Paper Industry MBR System

Savita Kalshan1 , Rajesh Dhankhar1*

, Rajesh Dhankhar1* , Shivani Narwal1

, Shivani Narwal1 , Amit Chhillar1, Poonam Yadav1

, Amit Chhillar1, Poonam Yadav1 , Sashi Yadav2

, Sashi Yadav2

1Department of Environmental Science, Maharshi Dayanand University, Rohtak, Haryana, India.

2University Institute of Engineering and Technology, Maharshi Dayanand University, Rohtak-124001, Haryana, India.

Corresponding Author E-mail: savita.rs.evs@mdurohtak.ac.in

DOI : http://dx.doi.org/10.13005/ojc/400126

Article Received on : 16 Oct 2023

Article Accepted on : 11 Jan 2024

Article Published : 19 Jan 2024

Reviewed by: Dr. Jyoti Sharma

Second Review by: Dr. M. Manjula Devi

Final Approval by: Prof. Dr. Murat HATİPOĞLU

This study investigates the design, configuration, and optimization of a membrane bioreactor (MBR) system for the amelioration of industrial effluent. The study focuses on mitigating membrane fouling and reusing the treated wastewater. The MBR system is designed and configured with different operating parameters, including nano-bubble technology and hydraulic retention time (HRT), to optimize the removal efficiency of pollutants. The effect of HRT on the percentage elimination of pollutants in the wastewater treated by MBR systems is investigated, and the dynamic relationship between the mixed liquor suspended solids (MLSS) and HRT is studied to optimize the biological treatment process. The relationship between permeate flux and temperature is also investigated to optimize the operational conditions of MBR systems. Trans-membrane pressure monitoring and cleaning techniques are employed to mitigate membrane fouling in MBR systems. It is assessed if it is feasible to reuse the treated wastewater for commercial purposes. According to the data, the MBR system with nano-bubble technology and a 12-hour HRT had the best pollution removal effectiveness (97.5%). It was discovered that the dynamic link between MLSS and HRT was crucial for optimising the biological treatment procedure, and that 25°C was the ideal temperature for MBR operation. The treated wastewater was found to be suitable for reuse in industrial applications, and the trans-membrane pressure monitoring and cleaning approaches were successful in reducing membrane fouling. With the potential to improve both the environment and the economy, the study's findings offer important insights into the design of long-term, sustainable MBR systems for the treatment of industrial wastewater.

KEYWORDS:Membrane Bioreactor; Pulp and Paper; Treatment; Reuse; Wastewater

Download this article as:| Copy the following to cite this article: Kalshan S, Dhankhar R, Narwal S, Chhillar A, Yadav P, Yadav S. Achieving High Removal Efficiency and Membrane Sustainability in Pulp and Paper Industry MBR System. Orient J Chem 2024;40(1). |

| Copy the following to cite this URL: Kalshan S, Dhankhar R, Narwal S, Chhillar A, Yadav P, Yadav S. Achieving High Removal Efficiency and Membrane Sustainability in Pulp and Paper Industry MBR System. Orient J Chem 2024;40(1). Available from: https://bit.ly/3S57yBB |

Introduction

The pulp and paper industry, a major player in the global economy, produced an estimated 419 million tons in 20191. Its wastewater, characterized by substances like lignin and cellulose, presents challenges due to its unique composition. If untreated, this wastewater poses environmental risks. Despite the industry’s significant contribution, its wastewater contains high levels of organic matter and pollutants, causing environmental pollution2. Efficient wastewater treatment is crucial for regulatory compliance, environmental protection, and the sustainable future of pulp and paper production. Membrane bioreactor (MBR) technology is increasingly recognized as a promising solution, offering high treatment efficiency, compactness, and low sludge production3.

Fouling of the membrane is a common issue in MBR systems, which can significantly reduce their performance and increase operational costs4. Furthermore, the selection of appropriate membrane materials, operational parameters, and system configurations can affect the treatment efficiency and economic feasibility of MBR systems5.

Polyethersulfone (PES) membranes had the best performance in terms of fouling resistance and organic matter removal efficiency studied the treatment effectiveness of MBR systems utilizing various types of membranes6. In a further study, the impact of hydraulic retention time (HRT) and solids retention time (SRT) on the efficacy of MBR systems was examined. It was discovered that longer HRT and SRT could increase the effectiveness of pollutant removal7. Despite these studies, there is still a research gap in the design and optimization of MBR systems for pulp and paper industry wastewater treatment. Future research is needed to investigate the optimization of MBR system configurations, the selection of appropriate membrane materials, and the impact of operational parameters such as aeration rate and pH on treatment efficiency and economic feasibility. The development of efficient and cost-effective MBR systems for pulp and paper industry wastewater treatment will not only contribute to environmental sustainability but also benefit the economic growth of the industry.

Due to its high efficiency and low sludge formation, the treatment of industrial wastewater using membrane bioreactor (MBR) technology has gained recognition as a promising alternative. Though, fouling of the membrane remains a significant challenge, which can reduce the performance of MBR systems and increase operational costs. To address these challenges, this study aims to investigate the design, configuration, and optimization of MBR systems for the treatment of industrial wastewater, with a focus on mitigating membrane fouling and reusing the treated wastewater.

Specifically, this study aims to:

Design and configure a membrane bioreactor with different operating parameters, including nano-bubble technology and hydraulic retention time (HRT), to optimize the removal efficiency of pollutants.

Investigate the effect of HRT on the percentage removal of pollutants in the wastewater treated by MBR systems.

Study the dynamic relationship between the mixed liquor suspended solids (MLSS) and HRT to optimize the biological treatment process.

Investigate the relationship between permeate flux and temperature to optimize the operational conditions of MBR systems.

Mitigate membrane fouling in MBR systems through trans-membrane pressure monitoring and cleaning techniques.

Evaluate the feasibility of reusing the treated wastewater for industrial applications.

The outcome of the present study will contribute to the development of efficient and sustainable MBR systems for the treatment of industrial wastewater. Furthermore, the reuse of treated wastewater can provide economic and environmental benefits by reducing water consumption and wastewater discharge.

Material methodology

Experimental configuration

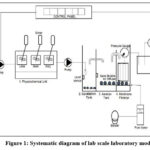

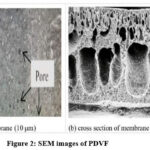

Experiment was conducted at the Bioremediation Laboratory of the Department of Environmental Science at MD University-Rohtak, Haryana, India. An advanced membrane bioreactor (MBR) was designed for treating pulp and paper (P&P) industry wastewater using an integrated chemical, biological, and membrane filtration unit. The operating conditions of the MBR are presented in Table 1. The MBR consisted of four tank units: A physicochemical treatment tank (10 L), an equalization tank (10 L), an aerobic tank (10 L), a membrane filtration tank (20 L). The flat sheet membrane, composed of Polyvinylidene difluoride (PVDF) from Mitsubishi Rayon, Japan, with a flux rate of 10 L/m2/hr and a pore size of 0.04-0.05 microns, was submerged in the membrane filtration tank. The total surface area of the membrane was 0.32 m2. Nano air bubble diffusers (Model no. ACO-003, 45W) from M/s Shenzhen Solarmy Technology Co. Ltd were used to supply oxygen and maintain high mixed liquor suspended solids (MLSS) in the membrane and aeration tank to treat the Paper & Pulp industry wastewater. A peristaltic pump was used to make sure a steady feed flow of wastewater into the inlet tank, while a suction pump was employed to regulate the permeate flow rate. A pressure gauge was utilised to measure the transmembrane pressure (TMP), and the level switch was employed to keep the MBR’s volume constant. Figure 1 shows the arrangement of the created model. Scanning electron microscopy (SEM) using a Zeiss EVO40 at magnifications of 10 mm and 100 mm was used to analyse the membrane surface area, as indicated in Figure 2.

Table 1: Operational condition of Designed Model.

|

Parameter |

Operating condition |

|

Hydraulic Retention Time (HRT), Hours |

12h, 8h, 6h |

|

Sludge Retention Time (SRT), days |

21 |

|

Mixed Liquor Suspended Solid (MLSS), g/l |

7.4-10.8 |

|

Dissolved Oxygen (DO), mg/l |

3-5 |

|

Temperature, |

22-25 |

|

Flux, L/m2h |

10.5 |

|

Trans Membrane Pressure (TMP), kPa |

2-30 |

|

Diffuser type |

Nano bubble |

|

Figure 1: Systematic diagram of lab scale laboratory module. |

Paper and Pulp wastewater and their operating conditions

The P & P industry wastewater samples were collected from the equalization tank of a factory located in Yamunanagar, Haryana, India, at the coordinates of 30°8’14.8812”N and 77°16’22.2312’E. The samples were collected as grab samples, with a total volume of 40L, and stored at 4°C to maintain sample integrity. The wastewater samples did not meet the permissible limits of the World Health Organization and Indian Standards, as outlined in Table 2. The advanced membrane bioreactor was operated once a week for a duration of one month, with dissolved oxygen levels ranging between 2-4mg/L and Mixed Liquor Suspended Solids (MLSS) concentrations of 9.4 g/L. The feed of inlet flux started at a rate of 15 L/m2h with a transmembrane pressure (TMP) of 2 kPa. The initial permeate flux started at 9 L/m2h with a permeate production rate of 2 min off and 5 min on for intermediate suction. Hydraulic retention time (HRT) and solid retention time (SRT) were controlled at 6 h and 14 days, respectively. The permeate flux was maintained through physical and chemical cleaning. Physical cleaning involved the use of tap and distilled water, while chemical cleaning was performed using NaOCl, 0.5% and 0.1% oxalic acid. The critical parameters of the membrane treatment system, such as Trans Membrane Pressure (TMP), flux and Specific Aeration Demand (SAD).

|

Figure 2: SEM images of PDVF |

Determination of TMP of membrane bioreactor

Trans-membrane pressure (TMP) is an essential parameter in MBR operation and refers to the pressure difference between the feed side and permeate side of the membrane. TMP is a critical factor because it directly affects the flux, or rate of water permeation, through the membrane.

A high TMP can lead to fouling or clogging of the membrane, reducing the flux and overall efficiency of the MBR system. Therefore, it is essential to monitor and control the TMP within a certain range to ensure optimal performance of the MBR. The formula for the trans-membrane pressure (TMP) of a membrane bioreactor can be expressed as:

TMP = (Pfeed – Ppermeate) – σ

where Pfeed is the pressure of the feed solution (kPa), Ppermeate is the pressure of the

permeate (kPa), and σ is the osmotic pressure (kPa).

Determination of Flux of membrane bioreactor

Flux in a membrane bioreactor (MBR) is the rate of permeate flow through the membrane per unit of membrane area. It is influenced by factors such as membrane material, feed characteristics, trans-membrane pressure, and hydrodynamics. To optimize flux, it is important to maintain a suitable trans-membrane pressure, control feed concentration, and prevent membrane fouling through proper mixing, aeration, and cleaning. A high and sustainable flux is critical for successful MBR operation. The formula for flux of a membrane bioreactor can be expressed as:

Flux (J): J = Q / A

Where J is the flux (L/m2.h), Q is the permeate flow rate (L/h), and A is the effective membrane area (m2).

Determination of Specific aeration demand (SAD) of membrane bioreactor

Specific aeration demand (SAD) is a parameter that is commonly used in the field of wastewater treatment to determine the amount of oxygen required to treat a specific quantity of wastewater. SAD is defined as the amount of oxygen required to remove 1 kg of biochemical oxygen demand (BOD) from 1 m³ of wastewater during aeration.

The formula for calculating SAD is:

SAD = (Total oxygen required for aeration / Volume of wastewater) / BOD

Where the total oxygen required for aeration is the total amount of oxygen required to treat the wastewater during aeration, and BOD is the biochemical oxygen demand of the wastewater.

Determination of HRT (Hydraulic Retention Time)

The amount of time wastewater remains in a treatment system is known as hydraulic retention time (HRT). It is frequently used to optimize the design and operation of wastewater treatment plants and is a crucial aspect in determining the efficacy of a treatment system.

The formula for calculating HRT is

HRT = V/Q

Where: HRT = Hydraulic Retention Time (in hours) V = Volume of the treatment system (in cubic meters or gallons) Q = Flow rate of the wastewater (in cubic meters per hour or gallons per minute)

The HRT is important because it affects the performance of various treatment processes such as sedimentation, biological treatment, and disinfection. If the HRT is too short, the treatment processes may not be able to remove pollutants effectively, resulting in poor water quality. On the other hand, if the HRT is too long, it can result in excessive treatment time and higher costs.

Determination of percentage of removal of pollutants

The effectiveness of the system in removing contaminants from wastewater is gauged by the percentage of removal rate in a Membrane Bioreactor (MBR). The concentration of a certain contaminant in the influent (incoming wastewater) and effluent (treated wastewater) are compared to calculate it.

The following equation can be used to determine an MBR’s percentage removal rate:

% Removal Rate = (Ci – Ce) / Ci x 100

Where: Ci = Pollutant Concentration in Input (in mg/L or ppm) Ce is the contaminant concentration in the effluent (in mg/L or ppm).

The percentage of removal rate is a crucial performance measure for MBR systems since it aids in determining how effectively contaminants are removed from wastewater throughout the treatment process. Additionally, it helps to operate and construct MBR systems more efficiently.

Table 2: Physico-chemical characterization of Paper & Pulp industry wastewater

|

Chloride (as Cl) (mg/l) |

< 600 |

< 600 |

2892 |

108 |

|

Total Suspended Solids, mg/L |

< 50 |

< 100 |

1822 |

6 |

|

Total Chromium as (Cr), (mg/L) |

< 2 |

< 2 |

0.21 |

0.02 |

|

Ammonical Nitrogen |

< 50 |

< 50 |

98 |

6.2 |

|

Nitrate (as NO3), (mg/l) |

< 10 |

< 10 |

0.68 |

0.02 |

|

Total Nitrogen (as N), (mg/L) |

< 100 |

< 100 |

128 |

4.9 |

|

Phenolic Compounds (as C6H5OH), (mg/L) |

< 1 |

< 1 |

0.58 |

0.0009 |

|

Sodium (as Na)., (mg/l) |

< 1000 |

< 1000 |

2365 |

12.2 |

|

Phosphorous (as P), (mg/l) |

< 10 |

< 10 |

30.2 |

8.2 |

|

Potassium (as K), (mg/l) |

< 50 |

< 50 |

302 |

21 |

|

Cobbalt, (mg/L) |

< 0.05 |

< 0.05 |

8.4 |

0.08 |

|

Arsenic (as As), (mg/l) |

< 0.1 |

< 0.2 |

0.009 |

0.0002 |

|

Lead (as Pb), (mg/l) |

< 0.1 |

< 0.1 |

8.4 |

0.33 |

|

Manganese (as Mn), mg/l |

< 0.2 |

< 0.2 |

0.08 |

0.002 |

|

Electrical Conductivity, (µmhos/cm) |

< 4000 |

< 4000 |

1860 |

1012 |

Result and discussion

Impact of HRT and Permeate Flux on Membrane Filtration System Performance over Time

Membrane filtration systems are widely used in wastewater treatment plants to remove contaminants and pollutants from water. Two key parameters that affect the performance of these systems are the hydraulic retention time (HRT) and the permeate flux. The HRT and permeate flux have a significant impact on the efficiency and effectiveness of membrane filtration systems. Studies have shown that changes in HRT and permeate flux over time can have a noteworthy impact on the generally treatment performance. The decrease in HRT or increase in permeate flux can result in reduced removal rates of contaminants, while an increase in HRT or decrease in permeate flux can improve treatment efficiency and reduce the likelihood of fouling.

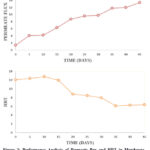

Fig. 3 displays the outcomes of the permeate flux and HRT for the advanced MBR system at various time intervals. Even though the suction pressure remained constant, each region’s flow rate and permeate flux reduced during the course of its 15-day operation, which led to higher HRT values. As a result, each operating region’s average HRT value over the 15-day span was reported. Membrane fouling, which results from the buildup of sludge cake on the membrane sheet’s surface, is what is thought to be responsible for the fluctuation in permeate flux and HRT. As the suction pressure was increased, the difference between the permeate flow at the start-up and end-up points grew from 6.4 L/m2.h at HRT of 12 h to 9.3 L/m2.h at HRT of 8 h to 12.4 L/m2.h at HRT of 6 h. The largest (12.1 h) and minimum (6.8 h) differences between the start-up and end-up values of HRT over the 15-day operation were also shown in the first and last regions, respectively, with average HRT values of 12 and 6 h. Low permeate flux, on the other hand, may be a sign of membrane fouling brought on by the accumulation of particles and other pollutants on the membrane surface. This might make it harder for water to flow, which would reduce the permeate flux. Several studies have investigated the impact of HRT and permeate flux over time in membrane filtration systems. For example, a study by Deng et al.8 found that a longer HRT and lower permeate flux were effective in reducing fouling and improving treatment efficiency over time. In contrast, a study by Kozak et al.9 found that a shorter HRT and higher permeate flux were more effective in removing contaminants and achieving higher removal rates. In conclusion, the impact of HRT and permeate flux over time is an important consideration in the design and operation of membrane filtration systems. The optimal combination of HRT and permeate flux will depend on the specific requirements of the treatment plant and the characteristics of the wastewater being treated. Understanding the relationship between these parameters and their impact on treatment performance is critical for achieving effective and efficient wastewater treatment.

|

Figure 3: Performance Analysis of Permeate flux and HRT in Membrane Filtration System over Time |

Dynamic relationship between MLSS and HRT

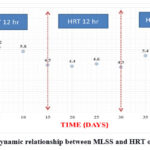

The fig.4 presented in this study depicts the dynamic relationship between the mixed liquor suspended solids (MLSS) and hydraulic retention time (HRT) over a 45-day period in a advanced membrane bioreactor. The MLSS concentration is an important parameter that reflects the active microorganism population in the bioreactor, while HRT represents the time that wastewater stays in the bioreactor. Initially, the MLSS concentration was 6.9 g/L, and the HRT was 12 hours. Over the first 15 days, the MLSS concentration decreased gradually to a minimum of 4.5 g/L. This was attributed to an inappropriate feeding condition, resulting in the deflocculation of active microorganisms. The bioreactor achieved equilibrium between the quantity of active bacteria and the supply of nutrients during this time. In Stage II, from day 20 to day 35, there was an increase in MLSS concentration, and this was accompanied by a decrease in HRT from 8 to 6 hours. The increase in MLSS concentration indicated that the number of active microorganisms was increasing. The decrease in HRT resulted in a higher nutrient-to-microorganism ratio, positively impacting the sustenance, proliferation, and growth of active cells. Stage III, covering the period from day 40 to day 45, revealed that the MLSS concentration remained relatively constant despite a significant decrease in HRT from 6 hours. This suggests that higher concentrations of particulate organic matter (POM) in the bioreactor can increase toxicity, hindering microorganism growth and activity. Overall, the data indicates that maintaining an appropriate nutrient-to-microorganism ratio is essential for the sustained growth and activity of microorganisms in the bioreactor. To optimize the bioreactor performance, it is crucial to maintain a balance between POM concentration, HRT, and MLSS concentration.

|

Figure 4: Dynamic relationship between MLSS and HRT over the time. |

Synergistic effect of HRT and nano air bubbles on wastewater treatment

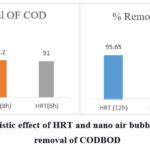

The presented data in fig. 5 shows the results of a study on the performance of a wastewater treatment plant over a 45-day period. The study measured the percentage of TDS, BOD, COD, and TSS removal in addition to the hydraulic retention time (HRT), or the period of time wastewater is held in the treatment facility.

The results indicate that the wastewater treatment plant was effective in removing pollutants, as evidenced by the high percentage removal rates of BOD, COD, TDS, and TSS. At the start of the study, the percentage removal of COD and BOD was high, at 95% and 96%, respectively. As the study progressed, there was a slight decrease in the percentage removal of COD and BOD, with the lowest values observed at day 45. This decrease in performance may be attributed to an accumulation of pollutants in the wastewater or a reduction in the number of active microorganisms in the treatment plant.

The study also measured the percentage removal of TDS and TSS, which are indicators of the total dissolved and suspended solids in the wastewater, respectively. The percentage removal of TDS remained relatively constant throughout the study, with values ranging from 96% to 98%. The percentage removal of TSS, on the other hand, showed a slight decrease over time, with the lowest value of 92.6% observed at day 40.

The use of nano air bubble diffusers in wastewater treatment has been shown to be an effective method for dropping the hydraulic retention time (HRT) and improving the removal efficiency of contaminants such as total suspended solids (TSS), total dissolved solids (TDS), biological oxygen demand (BOD), and chemical oxygen demand (COD). The results of a study conducted over a period of 45 days showed that the use of nano air bubble diffusers reduced the HRT to 6 hours, 8 hours, and 12 hours, resulting in higher removal percentages of COD, BOD, TDS, and TSS.

The shorter HRTs led to more efficient removal of contaminants because the nano air bubbles provided a larger surface area for the transfer of oxygen to the wastewater. The oxygen-rich environment created by the diffusers supported the growth of aerobic microorganisms, which are capable of breaking down organic matter and reducing the concentration of contaminants in the wastewater. Additionally, the nano air bubbles created turbulence and agitation in the wastewater, facilitating the movement of the microorganisms and increasing the contact time between the microorganisms and the contaminants.

The results presented in Figure 6 indicate that the nano air bubble technology can effectively remove both chemical oxygen demand (COD) and biological oxygen demand (BOD) from wastewater. Specifically, the technology achieved a COD removal rate of 93.75% and a BOD removal rate of 95.65% at an HRT of 12 hours. At an HRT of 8 hours, the COD removal rate was 91.2% and the BOD removal rate was 94%, while at an HRT of 6 hours, the COD removal rate was 91% and the BOD removal rate was 93.8%.

Several studies have investigated the combined effect of air bubble diffusers and HRT on the removal of COD, BOD, TSS, and TDS from wastewater. A study by Li et al.10 found that a combination of air bubble diffusers and a HRT of 6 hours resulted in the highest removal efficiency of COD and BOD from wastewater. Similarly, Adetunji et al.11 reported that a combination of air bubble diffusers and a HRT of 8 hours resulted in the highest removal efficiency of TSS and TDS from wastewater. Another study by Lian et al.12 reported that the use of nano air bubble diffusers in a sequencing batch reactor led to more efficient removal of COD and ammonia nitrogen.

|

Figure 5: Percentage removal of COD, BOD, TSS, and TDS on different HRT |

|

Figure 6: Synergistic effect of HRT and nano air bubbles on percentage removal of COD BOD |

Effect of Wastewater Temperature on the Performance of a Designed MBR Module

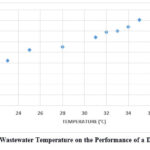

The results of this study shown in figure 7 that there is a positive correlation between wastewater temperature and membrane permeate flux in the designed MBR module. The permeate flux increased from 3.8 L/m2.h to 9.6 L/m2.h when the temperature rose from 22°C to 37°C. This is explained by the fact that when temperature rises, the viscosity of the feed decreases and the diffusivity of the solute increases.

These findings are consistent with previous studies that have shown the positive influence of temperature on membrane filtration in various types of MBR systems, such as submerged MBRs and anaerobic MBRs (AnMBRs)13,14. In addition, it has been reported that higher temperatures can enhance the biodegradation of organic matter and improve the removal of pollutants, which may further contribute to the increase in membrane permeate flux15. Overall, the result suggested that controlling the temperature of the wastewater in MBR systems can be an valuable approach to optimize membrane performance and improve treatment efficiency.

|

Figure 7: Effect of Wastewater Temperature on the Performance of a Designed MBR Module |

Mitigating Membrane Fouling in a Membrane Bioreactor through Trans-Membrane Pressure Monitoring and Cleaning Techniques

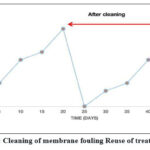

The present study investigates the membrane fouling in a membrane bioreactor (MBR) by measuring the trans-membrane pressure (TMP) during operation. The TMP measurements revealed an increase during the operational period, which is consistent with previous studies16,17. These studies have reported that membrane fouling can lead to a decline in permeate flux or an increase in TMP, depending on the operational mode18.

The TMP was recorded at regular intervals during MBR operation and was found to be a significant criterion for characterizing membrane fouling. The high sludge biomass concentration in the feed handled by MBR systems can cause membrane fouling, ensuing in a decrease in flux and an increment in TMP. After continuous operation for 25 days, the TMP reached a maximum (Figure 8), indicating severe membrane fouling. To address this issue, a thorough cleaning process was carried out on the fouled membrane, which involved physical and chemical methods such as sponge, water flush, and the use of NaOCl, 0.5% and 0.1% oxalic acid. During the nearly 24-hour cleaning period, feed flow was halted while the air supply in the aeration tank was maintained, and the microbial population was not expected to change significantly during membrane removal and cleaning.

|

Figure 8: Cleaning of membrane fouling Reuse of treated water |

The study demonstrated that the application of membrane bioreactor (MBR) technology was effective in treating wastewater generated from the pulp and paper industry. The filtrate obtained from the MBR process met the wastewater reutilization standards for makeup water of cooling towers and plant irrigations, as indicated in Table 2. This finding suggests that MBR technology can be a sustainable solution for reducing freshwater consumption and mitigating the environmental impact of the industry.

However, the effectiveness of MBR technology is subject to various factors, such as the quality of the influent wastewater, system design, and operational conditions. Therefore, the successful implementation of MBR systems requires meticulous planning and design to optimize treatment performance.

Conclusion

In this study, an advanced membrane bioreactor (MBR) was designed and operated to treat pulp and paper (P&P) industry wastewater using an integrated chemical, biological, and membrane filtration unit. The MBR consisted of four tank units, and a flat sheet membrane made of Polyvinylidene difluoride (PVDF) was used for membrane filtration. The P&P wastewater samples did not meet the permissible limits of the World Health Organization and Indian Standards, and the MBR was operated for one month with dissolved oxygen levels and Mixed Liquor Suspended Solids (MLSS) concentrations maintained at 2-4 mg/L and 9.4 g/L, respectively. The solid retention time (SRT) and hydraulic retention time (HRT) were controlled at 14 days, and 6 hours respectively, and physical and chemical cleaning were performed to maintain the permeate flux.

The study investigated the impact of HRT and permeate flux on the performance of the membrane filtration system over time. The results showed that changes in HRT and permeate flux can have a significant impact on the efficiency and effectiveness of membrane filtration systems. A decrease in HRT or increase in permeate flux can result in reduced removal rates of contaminants, while an increase in HRT or decrease in permeate flux can improve treatment efficiency and reduce the likelihood of fouling.

Membrane fouling, which results from the buildup of sludge cake on the membrane sheet’s surface, is what is thought to be responsible for the fluctuation in permeate flux and HRT. Low permeate flux may be a sign of membrane fouling brought on by the accumulation of particles and other pollutants on the membrane surface. The study highlights the importance of controlling HRT and permeate flux in membrane filtration systems to optimize treatment performance.

Overall, the results of this study demonstrate the feasibility of using an advanced MBR system for treating P&P industry wastewater. The findings could provide useful insights for the design and operation of membrane filtration systems for the treatment of other types of wastewater as well.

Acknowledgment

The authors are thankful to the Department of Environmental Sciences, Maharshi Dayanand University, Rohtak, India for their laboratory facility.

Conflict of Interest

The authors have no conflicts of interest regarding this study.

References

- Zambare VP; Christopher LP. Integrated biorefinery approach to utilization of pulp and paper mill sludge for value-added products. Journal of Cleaner Production. 2020 20;274:122791.

CrossRef - Izadi A; Hosseini M; Najafpour Darzi G; Nabi Bidhendi G; Pajoum Shariati F; Mosaddeghi MR. Perspectives on membrane bioreactor potential for treatment of pulp and paper industry wastewater: A critical review. Journal of Applied Biotechnology Reports. 2018, 1;5(4):139-50.

CrossRef - Rahman TU; Roy H; Islam MR; Tahmid M; Fariha A; Mazumder A; Tasnim N; Pervez MN; Cai Y; Naddeo V; Islam MS. The advancement in membrane bioreactor (MBR) technology toward sustainable industrial wastewater management. Membranes. 2023, 2;13(2):181.

CrossRef - Hamedi H; Ehteshami M; Mirbagheri SA; Rasouli SA; Zendehboudi S. Current status and future prospects of membrane bioreactors (MBRs) and fouling phenomena: a systematic review. The Canadian Journal of Chemical Engineering. 2019; 97(1):32-58.

CrossRef - Arias A; Feijoo G; Moreira MT. Environmental profile of decentralized wastewater treatment strategies based on membrane technologies. InCurrent Developments in Biotechnology and Bioengineering, 2020, (pp. 259-287). Elsevier.

CrossRef - Zinadini S; Vatanpour V; Zinatizadeh AA; Rahimi M; Rahimi Z; Kian M. Preparation and characterization of antifouling graphene oxide/polyethersulfone ultrafiltration membrane: application in MBR for dairy wastewater treatment. Journal of Water Process Engineering. 2015, 1;7:280-94.

CrossRef - Mannina G; Capodici M; Cosenza A; Di Trapani D; Ekama GA. The effect of the solids and hydraulic retention time on moving bed membrane bioreactor performance. Journal of Cleaner Production. 2018;170:1305-15.

CrossRef - Deng, L.; Guo, W.; Ngo, H. H.; Du, B.; Wei, Q.; Tran, N. H. & Li, J. Effects of hydraulic retention time and bioflocculant addition on membrane fouling in a sponge-submerged membrane bioreactor. Bioresource Technology, 2016, 210, 11-17.

CrossRef - Kozak, M.; Cirik, K.; & Başak, S. Treatment of textile wastewater using combined anaerobic moving bed biofilm reactor and powdered activated carbon-aerobic membrane reactor. Journal of Environmental Chemical Engineering, 2021,9(4), 105596.

CrossRef - Li, D.; Zhang, S.; Li, S.; Zeng, H.; & Zhang, J. Aerobic granular sludge operation and nutrients removal mechanism in a novel configuration reactor combined sequencing batch reactor and continuous-flow reactor. Bioresource technology, 2019, 292, 122024.

CrossRef - Adetunji, A. I.; & Olaniran, A. O. Treatment of industrial oily wastewater by advanced technologies: a review. Applied Water Science, 2021, 11(6), 98.

CrossRef - Lian, S.; Qu, Y.; Li, S.; Zhang, Z.; Zhang, H.; Dai, C., & Deng, Y. Interaction of graphene-family nanomaterials with microbial communities in sequential batch reactors revealed by high-throughput sequencing. Environmental research, 2020, 184, 109392.

CrossRef - Abdulsalam, M.; Che Man, H.; Isma Idris, A.; Faezah Yunos, K.; & Zainal Abidin, Z. Treatment of palm oil mill effluent using membrane bioreactor: Novel processes and their major drawbacks. Water, 2018, 10(9), 1165.

CrossRef - Mohammad, A. W.; Teow, Y. H.; Chong, W. C.; & Ho, K. C. Hybrid processes: Membrane bioreactor. In Membrane separation principles and applications, 2019, 401-470.

CrossRef - Asif, M. B.; Ansari, A. J.; Chen, S. S.; Nghiem, L. D.; Price, W. E., & Hai, F. Understanding the mechanisms of trace organic contaminant removal by high retention membrane bioreactors: a critical review.

Environmental Science and Pollution Research, 2019, 26, 34085-34100.

CrossRef - Xue, J.; Zhang, Y.; Liu, Y.; & El-Din, M. G. Effects of ozone pretreatment and operating conditions on membrane fouling behaviors of an anoxic-aerobic membrane bioreactor for oil sands process-affected water (OSPW) treatment. Water Research, 2016, 105, 444-455.

CrossRef - Zhang, M.; Peng, W.; Chen, J.; He, Y.; Ding, L.; Wang, A.; & Yu, H. A new insight into membrane fouling mechanism in submerged membrane bioreactor: osmotic pressure during cake layer filtration. Water research, 2013, 47(8), 2777-2786.

CrossRef - Souza, E.; Follmann, H. V. D. M.; Dalri-Cecato, L.; Battistelli, A. A.; Lobo-Recio, M. A.; Belli, T. J., & Lapolli, F. R. Membrane fouling suppression using intermittent electric current with low exposure time in a sequencing batch membrane bioreactor. Journal of Environmental Chemical Engineering, 2020,8(4), 104018.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.