Rheological Characteristics of Castor Oil Used as Biodegradable Lubricant

University of Bucharest, Faculty of Chemistry, Department of Physical Chemistry, 4-12 Elisabeta Blvd, 030018, Bucharest, Romania.

Corresponding Author E-mail: Istanciu75@yahoo.com

DOI : http://dx.doi.org/10.13005/ojc/360526

Article Received on : 21-09-2020

Article Accepted on : 23-10-2020

In this article I have presented the rheological characteristics of castor oil used as a biodegradable lubricant. The rheograms of castor oil have quite different slopes. The highest slope is at shear speed 3.3s-1, and the smallest slope is at 120s-1. From the representation of the dependence of the dynamic viscosity on the correlation coefficients at all the temperatures at which the castor oil has been was studied, the correlation coefficients have values close to the one value. The correlation coefficients have values between 0.985-0.990.

KEYWORDS:Biodegradable; Castor Oil; Rheology

Download this article as:| Copy the following to cite this article: Stanciu1 I. Rheological Characteristics of Castor Oil Used as Biodegradable Lubricant. Orient J Chem 2020;36(5). |

| Copy the following to cite this URL: Stanciu1 I. Rheological Characteristics of Castor Oil Used as Biodegradable Lubricant. Orient J Chem 2020;36(5). Available from: https://bit.ly/34GfH8f |

Introduction

Lately, due to environmental issues and more restrictive environmental laws, there has been a strong demand for “environmentally friendly” lubricants with as little negative impact as possible. In this context, lubricants obtained from plants are in the attention of tribologists, their main advantages being the relatively inexhaustible source, non-toxicity and biodegradability [1-6]. The problem is that, in addition to these advantages, the disadvantages are not to be neglected either: poor lubricating properties, instability to oxidation. Vegetable and animal oils are considered liquid lubricants and are chemically glycerin compounds with fatty acids. They consist of fatty acid fragments bound by an ester with glycerol (the result being triglycerides) [7-12]. May also contain in the raw state: phospholipids (8%), glycolipids (5%), sterile esters and sterols (5%), mono or diglycerides and free fatty acids (2%), waxes and other hydrocarbons (1%), but by various processes they can be totally or partially eliminated. Refined vegetable oils have a fairly uniform chemical composition compared to mineral ones and can be classified according to the fatty acids contained:

– saturated acids (without double bonds) myristic, palmitic, stearic acid, etc.,

– monounsaturated acids (double-linked only): oleic, erucic,

– polyunsaturated acids (with several double bonds): linoleic, linolenic,

– special acids (contain hydroxy, epoxy radicals, etc.).

Vegetable oils with high oleic acid content can be considered as highly monounsaturated, thus having better properties at low temperatures compared to other saturated vegetable oils.

Castor oil is obtained from the seeds of the castor plant, of which several varieties are known, the most cultivated being Ricinus communis and Ricinus sanguineus. The plant is native to India and has been acclimatized to South America, the USA, Italy, Turkey and France. In Romania it has been cultivated since 1930, with satisfactory results, but being a tropical plant requires a warmer, longer period of time for ripening. The regions where castor has been best cultivated are: Dobrogea, southern Muntenia and Oltenia, Bărăgan, and especially in calcareous soils. Castor oil is obtained by cold and hot pressing the grains, the yields generally differ from the theoretical ones, the qualitative assessment of the seeds being made after the manufacturing yields. Under correct technical conditions, an oil yield of 39… 40% is obtained from almost all assortments. Due to the high viscosity, high flammability and strong polar character, with high adhesion to the metal, castor oil has long been used simply or mixed with mineral oils to lubricate aircraft engines. Castor oil obtained by cold pressing is used in medicine, and that obtained by hot pressing for industrial uses. Castor oil is also obtained by extraction with gasoline without light fractions, but with some difficulties and can only be used for technical purposes. Castor oil contains 80-85% glycerides of hydroxyoleic oil, the rest being glycerides of palmitic and stearic acids. When castor oil comes from wet and partially degraded castor beans and is dark in color, it must be refined. The high viscosity causes some difficulties in the refining process.

The object of this paper is to determine the rheological behaviour for castor oil at shear rates ranging between 3 and 120 s-1 and temperatures ranging between 40 and 100oC.

Material and Methods

The castor oil used in this work is provided by a company in Bucharest, Romania. In this paper we studied only castor oil not additives.

Castor oil have been investigated using a Haake VT 550 Viscotester developing shear rates ranging between 3 and 120s-1 and measuring viscosities from 104 to 106 mPa.s when the HV1 viscosity sensor is used. The temperature ranged between 40 and 1000C and the measurements were made from 10 to 100C. The accuracy of the temperature was 0.10C [5-13].

Results and Discussion

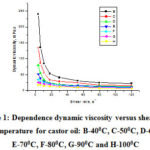

Figure 1 shows the dependence of the dynamic viscosity of the shear speed at all the temperatures at which the castor oil has been was studied. The curves obtained exhibit an exponential decrease at low temperatures and at high temperatures the decrease becomes less significant.

|

Figure 1: Dependence dynamic viscosity versus shear rate at temperature for castor oil: B-400C, C-500C, D-600C, E-700C, F-800C, G-900C and H-1000C |

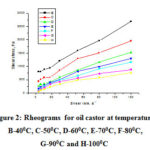

Figure 2 shows the reograms of castor oil at all temperatures at which the oil was studied. From the graphical representation of the dependence of the shear rate and the shear voltage, straight lines are obtained which have different slopes depending on the temperature at which the oil was studied. The highest slope is at 400C and the smallest at 1000C.

|

Figure 2: Rheograms for oil castor at temperature: B-400C, C-500C, D-600C, E 700C, F-800C, G-900C and H-1000C |

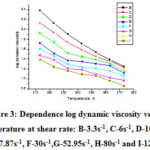

Figure 3 shows the log dependence of dynamic temperature viscosity at all shear rates. The straight with the highest slope is at the shear speed 3.3s-1, and the smallest slope is at 120s-1.

|

Figure 3: Dependence log dynamic viscosity versus temperature at shear rate: B-3.3s-1, C-6s-1, D-10.6s-1, E-17.87s-1, F-30s-1,G-52.95s-1, H-80s-1 and I-120s-1 |

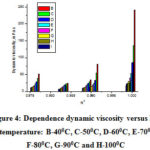

Figure 4 shows the dependence of the dynamic viscosity as on the correlation coefficients at all the temperatures at which the castor oil was studied. All correlation coefficients have values close to the one value.

|

Figure 4: Dependence dynamic viscosity versus R2 at temperature: B-400C, C-500C, D-600C, E-700C, F-800C, G-900C and H-1000C |

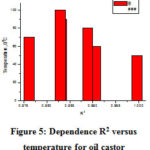

If the temperature is plotted as a function of correlation coefficients, a reduction of the values of the correlation coefficients to the values of 0.985-0.990 is being can ben observed.

|

Figure 5: Dependence R2 versus temperature for oil castor |

Conclusions

In this article I have presented the rheological characteristics of castor oil used as a biodegradable lubricant. The rheograms of castor oil have quite different slopes. The highest slope is at shear speed 3.3s-1, and the smallest slope is at 120s-1.

From the representation of the dependence of the dynamic viscosity on the correlation coefficients at all the temperatures at which the castor oil has been was studied, the correlation coefficients have values close to the one value. The correlation coefficients have get values between 0.985-0.990.

References

- Alonso M.L., Garzon E., Melcon B., Zapico J. 1990, Alimentaria, 27(213), 53-57.

- Rao M.A 1977, Journal Texture Studies, 8, 135-168.

CrossRef - Rao M.A., Cooley J.H. 1992, Journal Texture Stu-dies, 23, 415-425.

CrossRef - Rosen R.M., Forster W.E. 1978, Journal Coating Technology, 50, 456-468.

CrossRef - Stanciu I., 2018, Journal of Science and Arts, 1(42), 197-202.

- Moretto E., Fett R. 1998, Tecnologia de oleos e gorduras vegetais na industria de alimentos, Sao Paolo, Varela, 43–156.

- Santos J.C.O., Santos I.M.G., Souza, A.G. 2005, Journal of Food Engineering, 67, 401.

CrossRef - Eiteman M.A., Goodrum J.W. 1993, Transactions ASAE, 36, 503-507.

CrossRef - Stanciu I. 2017, Journal of Science and Arts, 4(41), 771-778.

- Stanciu I. 2018, Journal of Science and Arts, 2(43), 443-458.

- Femlab, Chemical Engineering Module, Version 2.3.COMSOL AB.2002.

- Goodrum J.W., Geller D.P., Lee S.A. 1998, Thermochimica Acta, 311, 71-.79.

CrossRef - Stanciu I., 2012, Analele Universitatii “Ovidius” Constanta – Seria Chimie, 23(1), 27-30.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.