Reduced Allergenicity of Foods of Plant Nature by the Method of Enzymatic Hydrolysis

Rimareva L.V, Sokolova E. N, Serba E. M, Borshchevа Yu. A, Kurbatova E. I. and Krivova A. Yu.

All-Russian Research Institute of Food Biotechnology – a branch of the Federal, State Budget Institution of Science "Federal Research Center of Food, Biotechnology, and Food Safety".

Corresponding Author E-mail: elenaivkurbatova@gmail.com

DOI : http://dx.doi.org/10.13005/ojc/330448

The protein, amino acid composition of crops used in the production of bakery products has been thoroughly studied. The protein content amounted in wheat (21%), rye (18,2%), corn (13.1 %). Higher biological value proteins differed rye that 46.7% of the essential amino acids. The range for solubility of proteins of wheat, rye and corn wasset. The highest albumin content was noted in the composition of proteins of corn flour (15,5%); globulins - rye flour (24,5%), glutelins - in wheat (38.6 %). Fractional composition of proteins in cereals are represented by fractions in the range from 10 to 97 kDa. Wheat raw materials were marked by a high content of high molecular weight proteins to 97 kDa, as well as glyadenovo and glutaminova fractions in the range from 35 to 44 kDa. It is typical of corn to have the polypeptides of a molecular weight of 50 kDa, and as for rye - to 60 kDa .The processing of grain raw materials complexes of proteases, endo - and ecstasty was carried out. Enzymes were selected by culturing the filamentous fungi Aspergillus niger (enzyme system - 1) and Aspergillus oryzae (enzyme system -2). The use of enzymes -2 ( 4 units PS/g) was provided by the accumulation of amine nitrogen in the grain fermentalistic 116,1-130.6 signatures mg%. The formation of free amino acids in slurries of rye amounted to 10% of the total. When using the enzyme system -2 there was a significant decrease in the molecular weight of the polypeptides of 35-40 kDa in all samples of grain crops. Infermentalistic - wheat, rye and corn got a reduced content of allergenic proteins,which ensures the production of the modified products of cereal crops with reduced sensitizing activity.

KEYWORDS:Enzymatic hydrolysis; Proteins of cereals; Allergenicity; Protease; Products with reduced allergenic activity

Download this article as:| Copy the following to cite this article: Rimareva L. V, Sokolova E. N, Serba E. M, Borshchevа Y. A, Kurbatova E. I, Krivova A. Y. Reduced Allergenicity of Foods of Plant Nature by the Method of Enzymatic Hydrolysis. Orient J Chem 2017;33(4). |

| Copy the following to cite this URL: Rimareva L. V, Sokolova E. N, Serba E. M, Borshchevа Y. A, Kurbatova E. I, Krivova A. Y. Reduced Allergenicity of Foods of Plant Nature by the Method of Enzymatic Hydrolysis. Orient J Chem 2017;33(4). Available from: http://www.orientjchem.org/?p=35737 |

Introduction

Feeding relates to life-sustaining functions, so the intolerance to any food ingredients by the body raises sharply the question about the need for the development of new or modification of known socially significant products[1]. It is necessary to develop food technology, including cooking during which in the food manufacturing process toxic substances would be destroyed or transformed into harmless [2]. Some prospects for feeding optimization are opened by the improvement of the food protein composition by ensuring it [the last one] with the relevant peptides, amino acids. Peptide hydrolysates can be recommended for feeding weakened organisms, during short-term diets, at high physical loads, with a food intolerance, or intolerance.[3] In recent years the number of people affected by allergic diseases caused by food products, for example, consumption of bakery and cereal products that are rich in high molecular weight proteins significantly increased. Despite the fact that the consumption of bread in the world in general and in Russia in particular is reduced, up to the present time, one of the most important products in the food basket, has always been and remains bread. The level of consumption of bread in Russia as well as in the European countries is 80-95 kg per capita per year [4]. Spare proteins of cereals have strong allergenic properties. For wheat they are gliadin and glutenin – the main components of gluten,the shares/content of which amount40-45 and 35-40 % of the total protein respectively, for rye – scalini and glutenin, the content of which is almost equal to 30-50% of total protein, corn – Seine 50-55 and glutamine 30-45% of the total protein.[5] The molecular weight of components in the spectrum of gliadins (from 10 to 20 fractions) varies from 27 to 75 kDa, for glutenin the molecular weight from 41 to 44 kDa is characteristic [6]. The profile and distribution of fractions of Zein in corn flour is represented by polypeptides of α-Zein (24 kDa and 26 kDa); γ-Zein (22 kDa); the β-Zein (17 kDa ), and δ-Zein, respectively [7]. The most effective method of reducing the toxicity of protein crops is its biocatalytic modification. In the process of hydrolysis by proteolytic enzymes break down protein into peptide fragments having a much lower sensitizing activity [8]. In addition, enzymatic hydrolysates retain all the amino acids contained in raw materials, including essential amino acids.

The purpose of this study was to investigate the influence of enzyme preparations of proteolytic action on the degree of degradation of the protein crops for the production of dietary products with reduced allergenicity.

Materials and Methods

The object of this study was wheat, rye and corn flour. As enzyme systems (FS) the complex of fungal proteases (FS-1), obtained by culturing filamentous fungus Aspergillusniger, was used; (FS-2) is a complex of proteases synthesized by the micromycete A. oryzae. Proteolytic activity was determined by the degree of hydrolysis of hemoglobin [9] . The content of amine nitrogen -by the copper method in the absence of ammonium salts [10]. Total protein content was determined by the Kjeldahl method on automatic [11].

The process of hydrolysis of protein substances of raw grain was carried out by FS proteolytic activities in selected earlier selected conditions: within 2 h at 50°C With рН5,5 [8], the concentration of flour suspension – 30%. To determine the degree of proteolysis of the protein composition of the feedstock and fermentalistic the method of electrophoresis in polyacrylamide gel was used[12].

The composition of the total proteins in cereals was determined by the composition of the individual fractions, the classification of which is based on the principle of solubility [11]. Protein fractions: albumins, globulins, and glutelin that prolamins were extracted by successive processing of flour with water, 5-10% sodium chloride solution, 60-80% aqueous solution of alcohol and of 0,1-0,2% solution of sodium hydroxide. Albumins were fractionated from globulins with the help of ammonium sulfate. The globulins were precipitated at 50%, and albumin at 100% saturation solution of ammonium sulphate. Liquid and solid fractions were separated in a centrifuge (3000 rpm). The content of total and free amino acids were determined by amino acid analyzer HPLC “KNAUER” (Germany).

Results

Protein and amino acid composition of grain raw materials and products of the enzymatic hydrolysis has been researched. Crops differed in protein content. The highest protein content was observed in wheat (21%) and rye (18.2 %), the least one- in corn (13.1 %),with rye proteins containing 46.7% of the essential amino acids having a higher biological value (table. 1).

Table 1: The content of essential amino acids in grain raw materials.

| Amino acid (AA) | Content of essential amino acids, mg/g of flour | ||

| Corn | Rye | Wheat | |

| Threonine | 0,454 | 0,489 | 0,691 |

| Valine | 0,523 | 0,608 | 0,835 |

| Methionine | 0,224 | 0,205 | 0,283 |

| Isoleucine | 0,478 | 0,419 | 0,742 |

| Leucine | 1,595 | 1,036 | 1,750 |

| Phenylalanine | 0,868 | 0,944 | 1,406 |

| Lysine | 0,436 | 0,672 | 0,743 |

| Tryptophan | 2,200 | 5,644 | 4,263 |

| The total number of essential amino acids | 6,778 | 10,017 | 10,713 |

| The total number of amino acids,of them irreplaceable,% of the total number of AA | 16,33841,5 | 21,46746,7 | 24,86843,1 |

Characterization of the protein composition of the investigated samples of wheat, rye and corn on solubility is presented in figure 1. The highest albumin content was noted in the composition of proteins of corn flour (15,5%); globulins – that of globulins – in rye flour(24,5%), glutelins – in wheat (38.6 %).

|

Figure 1: Components composition was of protein in crops. |

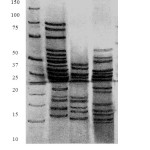

The study of the fractional composition of proteins of cereals, selected for the degradation of the allergenic proteins of grain raw materials was carried out using the method of electrophoresis in page. Analysis of the fractional composition of the investigated cereal crops showed the presence of protein fractions in the range from 10 to 97 kDa. At the same time raw wheat was noted to have a higher content of high molecular weight proteins, including glyadenovo and glutaminova fractions in the range from 35 to 44 kDa. In rye and corn raw material the molecular weight of protein fractions was significantly lower. For corn it is typical to have the polypeptides of a molecular weight of 50 kDa, and for rye – to 60 kDa (Fig. 2).

|

Figure 2: The electrophoretogram was of native protein crops (M 1–marker 10-250 kDa; 1–wheat; 2–corn; 3–rye). |

In the production of bread and bakery products, cereal grains as the primary ingredient flour derived from wheat, rye or their mixture, and corn is used. If to qualify the crops for the degree of sensitizing activity of proteins, then we can talk about this trend: wheat – rye – corn. [13, 14]. With the goal of creating a product of low toxicity of dietary protein, it is necessary to reduce the length of the protein chain with the formation of peptides. Studies in this area are an important link in the solution of the fundamental problem of ensuring a living body with a complete protein food [15, 16].

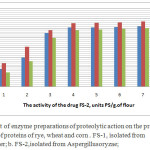

For the purpose of selecting dosage of complex proteolytic systems the concentration of the latter was varied from 1 to 7 units of PS/g of flour. The criterion for evaluation was the level of formation of the amine nitrogen as a result of hydrolysis of proteins in the studied samples of wheat, rye and corn flour.

The results of the research demonstrated that the concentration of the drug 6 units PS/g of flour for FS-1, is optimal from both economic and hydrolytic sides of the process, whereas for FS – 2 the flow dose was lower and amounted to 4 units PS/g of flour (Fig.3). It is important to note that as a result of exposure of FS – 1 the level of accumulation of amino nitrogen in the grain fermentalistic reached 97.2-101, 1 mg%. for FS – 2 – respectively 116,1-130.6 signatures mg%. Feature of the catalytic properties of proteolytic enzymes is their specificity in relation to the type of peptide bond and the mechanism of their action. Therefore, even in terms of the use of complex enzyme preparations with different specificity, the process of formation of free amino acids is limited, and the main products of enzymatic hydrolysis are the peptides with different molecular weight.

|

Figure 3: Effect of enzyme preparations of proteolytic action on the process of hydrolysis of proteins of rye, wheat and corn . FS-1, isolated from Aspergillusniger; b. FS-2,isolated from Aspergillusoryzae; |

The analysis of amino acids as a result of exposure of enzyme preparations was carried out on concentrated suspensions (30%)of cereals (tabl.2). Amino acids obviously do not cause allergic reactions. The results of the research showed that the impact of FS -2 features a deeper degree of hydrolysis of proteins for all the crops. The accumulation of free amino acids occurred more intensively in the suspension of rye, and the level of free amino acids when using the dosage of FS- 2 was 10% of the total, while the figure for FS-1 was respectively of 7.6.

Table 2: The contents of free amino acids in fermentalistic grain suspensions depending on the enzyme complex.

| Amino acid (AA) | Contents of AA, mg/g of flour. | |||||

| Corn | Rye | Wheat | ||||

| FS- 1 | FS- 2 | FS- 1 | FS- 2 | FS -1 | FS- 2 | |

| Threonine | 0,102 | 0,116 | 0,262 | 0,279 | 0,129 | 0,142 |

| Valine | – | 0,023 | 0,031 | 0,045 | 0,030 | 0,031 |

| Methionine | – | – | – | – | – | – |

| Isoleucine | – | – | 0,038 | 0,036 | 0,027 | 0,049 |

| Leucine | 0,020 | 0,036 | 0,035 | 0,058 | 0,029 | 0,042 |

| Phenylalanine | – | 0,015 | 0,011 | 0,047 | – | 0,021 |

| Lysine | 0,038 | 0,040 | 0,032 | 0,039 | 0,012 | 0,024 |

| Tryptophan | 0,302 | 0,429 | 0,309 | 0,637 | 0,349 | 0,551 |

| The total number of available A A/ AA is indispensable;in% of the total numberof AA/AA irreplaceable | 1,248/0,4627,6/2,9 | 1,469/0,6599,0/4,1 | 1,739/0,7188,1/3,3 | 2,151/1,14110,0/5,3 | 1,433/0,5765,8/2,3 | 1,908/0,8607,8/3,5 |

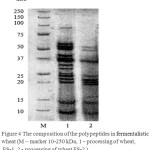

For a more detailed study of the possibility of liberation from of proteins having allergenic activity, in the manufacture of products using such cereals as wheat, rye and corn was to study the composition of polypeptides in fermentalistic plant, obtained by the action of the investigated proteolytic enzymes has been thoroughly studied. (Fig. 4-6).

|

Figure 4: The composition of the polypeptides in fermentalistic wheat (M – marker 10-250 kDa, 1 – processing of wheat, FS-1, 2 – processing of wheat FS-2 ). |

|

Figure 5: The composition of polypeptides in fermentalistic corn (M – marker 10-250 kDa, 1 – processing of maize, FS-1, 2 – processing of corn FS-2) Click here to View figure |

|

Figure 6: The composition of polypeptides in fermentalistic rye (M – marker 10-250 kDa, 1 – processing of rye, FS-1, 2 – processing of rye FS-2). |

Processing suspensions of grain raw materials by enzyme preparations of proteolytic action showed that the best results were obtained using the FS – 2. In this case, there was a significant decrease of molecular weight of polypeptides 35 of 40 all the samples of fermentalistic . The results of the use of FS – 1 are less effective , molecular weight of a significant fraction of the proteins remained at the level between 45 and 75 kDa.

Conclusion

It is shown now that pre-treatment of grain raw materials by enzyme preparations of FS-2, obtained by culturing filamentous fungus Aspergillusoryzae, allows to get rid of allergenic proteins in cereals such as wheat, rye and corn, and provides the production of the modified products of cereal crops with reduced sensitizing activity and is enriched with essential amino acids.

Acknowledgement

The research was supported by grant of the Russian Science Foundation № 16-16-00104.

References

- Bond, G. Natural eating: Eating in harmony with our genetic programming. 2003, 336

- Tutelian, V. A.; Khavinson, V. Kh.; Malinin, V. V. Physiological role of short peptides in nutrition. Bulletinof experimental biology and medicine2003,135, 4-10

- Falalyeyeva, T. M.; Samonina, G. E.; Beregovaya, T. V. Effect of glyprolines on homeostasis of gastric mucosa in rats with stress ulcers. Bulletin of experimental biology and medicine. 2010, 149, 30-33

CrossRef - Official website of the world health organization – URL: http://www.who/int/ru/

- Kolher, P. V.; Sidorovich, O. I.; Martynov, A. I.; Luss, L. V.; Repin, T. Y. Plant food allergens. GP SSC “Institute of Immunology of FMBA of Russia”, http://www.allergya.ru

- Biochemistry of grain. Glutelin and gliadin . http://hleb-produkt.ru/biohimiya-zerna/188-gliadin-i-glyutenin-pshenicy.html

- Stanchev, A. S.; Nasridinov, A. S; Teshaev, H. I.; Muhidinov, Z. K.; Khalikov, D. H. Turbidimetric titration Zein of corn flour. Reports of the Academy of Sciences of the Republic of Tajikistan.2007, 50, 35-46

- Kurbatova, E. I.; Rimareva, L. V.; Sokolova, E. N.; Borshcheva, Y.A. Biotechnological aspects of production of hypoallergenic foods from wheat feedstock.Production of alcohol and distilled sinisgalli.2015,2, 10-14

- Serba, E. M.; Overchenko, M. B.; Ignatova, N.I.; Sokolova E. N.; Kurbatova, E. I. Development of national standards on methods for determining the activity of enzyme preparations for food industry.Food industry.2013,7, 40-44

- Polyakov, V. A. Instructions for the technochemical control of spirit production.2007,780

- Shleikin, A. G.; Skvortsova, N. N.; Blandov, A. N. Proteins. Enzymes. Vitamins. Biochemistry.Laboratory tutorial.2015,106

- Struchkova, I. V.; Kolesova, E. A. Theoretical and practical bases of carrying out electrophoresis of proteins in polyacrylamide gel.Nizhny Novgorod: Nizhny Novgorod State University.2012,60

- Verschuren, P. M. Functional Foods: Scientific and Global Perspectives (Summary Report). British J. Nutrition. 2002,88, 125-130

CrossRef - Halavach, T. N.; Kurchenko, V. P.; Zhygankov, V. G.;Evdokimov, I. A. Determination of physicochemical, immunochemical and antioxidant properties, toxicological and hygienic assessment of whey protein concentrate and its hydrolysate.Foods and Raw Materials. 2015,3, 105-114

CrossRef - Kurchenko, V. P.; Golovach, T. N.; Chervyakovskii, E. M.; Simonenko, S. V.; Kharitonov, V. D. Whey protein partial hydrolysates for specialized and infant nutrition. Russian Agricultural Sciences. 2011, 37, 34-38

CrossRef - Halavach, T. M.; Kurchenko, V. P.; Albulov, A. I. Enzymatic hydrolysis of milk proteins as a basis of specialized food products biotechnology. Scientific Bulletin of Ural. 2014, 25(104), 69-79

This work is licensed under a Creative Commons Attribution 4.0 International License.