Optimization of High-Efficiency CdS/CdTe Thin Film Solar Cell Using Step Doping Grading and Thickness of the Absorption Layer

Masoud Sabaghi1, Abbas Majdabadi1, Saeid Marjani1,2,* and Saeed Khosroabadi3

1Laser and Optics Research School, Nuclear Science and Technology Research Institute (NSTRI), Tehran, Iran

2Department of Electrical Engineering, Ferdowsi University of Mashhad, Mashhad, Iran

3Department of Electrical Engineering, Imam Reza International University, Mashhad, Iran

DOI : http://dx.doi.org/10.13005/ojc/310232

Article Received on :

Article Accepted on :

Article Published : 29 May 2015

In this paper, the influence of stepped doping of the absorber layer on performance of Cadmium Sulfide/Cadmium Telluride (CdS/CdTe) solar cell has been investigated. At first, the electrical characteristics of conventional CdS/CdTe solar cell is validated with fabricated CdS/CdTe solar cell. To improve the maximum efficiency of CdS/CdTe solar cell, the doping and thickness of the absorption layer are optimized. By step doping concentration within the absorber layer using buffer layer back contact and the increase in stepping gradient of the doping of CdTe layer, improved the conversion efficiency about 2.4% were obtained. The open-circuit voltage, short-circuit current density, fill factor and total area conversion efficiency of optimized solar cell structure are 952 mV, 25.97 mA/cm2, 78.5% and 18.7% under global AM 1.5 conditions, respectively.

KEYWORDS:Optimization; High efficiency; Step doping grading; Cadmium Sulfide/Cadmium Telluride (CdS/CdTe); Thin film solar cell

Download this article as:| Copy the following to cite this article: Sabaghi M, Majdabadi A, Marjani S, Khosroabadi S. Optimization of High-Efficiency CdS/CdTe Thin Film Solar Cell Using Step Doping Grading and Thickness of the Absorption Layer. Orient J Chem 2015;31(2). |

| Copy the following to cite this URL: Sabaghi M, Majdabadi A, Marjani S, Khosroabadi S. Optimization of High-Efficiency CdS/CdTe Thin Film Solar Cell Using Step Doping Grading and Thickness of the Absorption Layer. Orient J Chem 2015;31(2). Available from: http://www.orientjchem.org/?p=8869 |

Introduction

One of the most promising new developments in the field of solar research is thin film technologies. Due to using simpler deposition processes as compared with conventional techniques, thin film solar cells are much cheaper to manufacture. Polycrystalline CdTe thin films are normally used in a CdS/CdTe heterojunction configuration due to the high optical absorption coefficient. N. Amin et al proposed a ZnTe buffer layer as a back surface reflector in order to form an ohmic contact which improves the efficiency [1]. The CdS films with highly n-type as a suitable window layer affect the cell’s conversion efficiency where thinner CdS films produce higher short circuit current densities [2]. The maximum efficiency for CdS/CdTe solar cells were 28–30% [3, 4] that have increased by only 1.5% during the last 17 years [5-9]. Previous researchers reported 16% and 16.5% for maximum cell efficiency of CdS/CdTe solar cells [10-13]. The best CdS/CdTe solar cells demonstrated the NREL show 17.3% and 18.7% for cell efficiency; and 12.8% and 13.1% for module efficiency at the lab condition [14, 15]. Consequently, today major challenge is increasing the efficiency of CdTe thin film solar cells.

Structure, Model and its validation

When modeling thin film solar cells, it is essential to take into account the interaction of optical and electrical that occur during the solar cells operation. The fundamental equations are electrostatic potential and carrier densities, which link together. The primary equations are Poisson’s Equation, the continuity equations and transport equations that derived from Maxwell’s laws. Furthermore, The Concentration-Dependent Low Field Mobility model, Shockley-Read-Hall recombination model and SRH Concentration-Dependent Lifetime were used to model the doping-dependent low-field mobility, recombination model and carrier lifetimes, respectively. These equations are solved self-consistently with Silvaco ATLAS oftware [16].

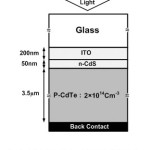

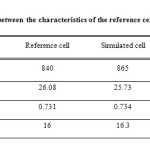

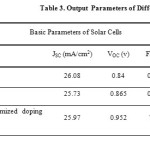

In this paper, we were used an experimentally-fabricated CdS/CdTe cell as a reference cell [12], and our simulation results are very close to the previous experimental results [12]. Therefore, the results can be basically valid for an actual cell with the proposed configuration. Figure 1 shows the reference cell structure where glass is used as the substrate. Its layers were consisted of 200 nm indium-tin-oxide (ITO), 50 nm CdS, 3.5μm CdTe. Table 1 listed all parameters used for simulation. It show an open-circuit voltage of 840 mV, a short-circuit current density of 26.08 mA/cm2, a fill factor of 0.731, and a conversion efficiency of 16.0% under AM 1.5 conditions. Table 2 compares the experimental results of JSC, VOC, fill factor, and cell efficiency with the simulated ones. As seen, the simulated results quite close to the actual experimental data.

![Table1: Best Physical Parameters [1].](http://www.orientjchem.org/wp-content/uploads/2015/05/Vol31_No2_Opt_Msoud_T1-150x150.jpg) |

Table1: Best Physical Parameters [1]. Click here to View table |

|

Figure1: Schematic structure of the reference cell. Click here to View figure |

|

Table2: Comparison between the characteristics of the reference cell and the simulated cell. Click here to View table |

Results and discussion

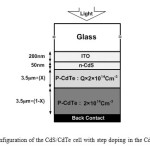

The step doping profile increases the efficiency of the CdS/CdTe cell due to formation of built-in electrical field that assists carrier migration and reduces the charge storage time and series resistance of the absorbing layer. The step doping profile can be form with divination of the absorption layer into two layers with different doping levels. The thickness and doping coefficients of the top layer of CdTe layer have defined with X and Q parameters, respectively. The thickness of the top and the bottom layer were set as 3.5×X (μm) and 3.5× (1-X) (μm), respectively. The top and bottom layer doping concentrations were set as Q×2×1014cm-3 and fixed 2×1014 cm-3 value, respectively. Figure 2 shows this cell configuration schematically.

|

Figurte2: Configuration of the CdS/CdTe cell with step doping in the CdTe layer. Click here to View figure |

In addition to optimizing the doping levels, various structures by using step doping grading of the CdTe layer were also investigated in order to achieve best device performance. Therefore, the both doping and thickness of the top CdTe layer were optimized. An increase in the step doping gradient causes the decrease of charge storage time considerably. As compared with the uniformly doped reference cell, all step graded doping structures exhibited higher efficiency.

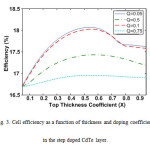

Figure 3 shows the effect of varying X and Q in cell efficiency of the new structure. As can be seen, the efficiency is the maximum (18.07%) for X=0.64 and Q=0.05. The fill factor of 0.818 obtained for the best step graded doping structure.

|

Figure3: Cell efficiency as a function of thickness and doping coefficients in the step doped CdTe layer. Click here to View figure |

Figures 4 and 5 show characteristics of the proposed structure for various values of Q (Q=0.75, 0.5 and 0.05). As seen these figures, the efficiency is maximum at the value of Q=0.05.

|

Figure4: Current-voltage curve of the optimized CdS/CdTe solar cell. Click here to View figure |

|

Figure5: Power curve of the optimized CdS/CdTe solar cell. Click here to View figure |

One of the major challenges associated for the fabrication of efficient and long-term stable CdS/CdTe solar cell is the formation of a stable, low resistance, non-rectifying contact to p-CdTe thin film. A high work function metal is required to make good ohmic contact to p-CdTe since CdTe is a p-type semiconductor with high electron affinity while most metals do not have sufficiently high work functions. Therefore, Schottky-barrier contacts to p-CdTe absorber layers are normally used. The presence of a back contact barrier can significantly affect the current–voltage characteristics of a CdTe cell, primarily by impeding hole transport. Furthermore, it causes the current-limiting effect referred to as “rollover” causing form Schottky, or blocking barriers. The use of heavily doping extra buffer layer between the CdTe and metal back contact interface is a typical approach to overcome this problem. Moreover, the buffer layers are essential for achieving highly efficient solar cells. Figure 6 shows the resulted structure with the optimized CdTe thickness.

|

Figure6: Cell efficiency as a function of doping in the ZnTe layer. Click here to View figure |

In order to form an ohmic contact, the 100 nm of Zinc Telluride (ZnTe) with a direct band gap of 2.28 eV was used as a back contact buffer layer in this work. Since ZnTe can dope highly p-type, the efficiency of our structure as a function of its doping was plotted. Figure 7 shows impact of increasing in impurity of the ZnTe layer on the J-V characteristics. As seen, due to increasing the open-circuit voltage, the efficiency increase.

|

Figure7: Cell structure with optimized absorption layer and BSF layer. Click here to View figure |

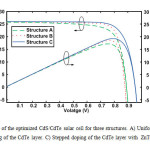

Another attractive quality of the ZnTe is the low valence band discontinuity with CdTe. Therefore, it provides no drawback to the flow of holes towards the contact. The efficiency of new structure was 18.7%. Figure 8 shows calculated J-V data for following three structures:

A) Uniform doping of CdTe layer

B) Stepped doping of the CdTe layer

C) Stepped doping of the CdTe layer with the ZnTe buffer layer.

|

Figure8: Current-voltage curve of the optimized CdS/CdTe solar cell for three structures. A) Uniform doping of CdTe layer. B) Stepped doping of the CdTe layer. C) Stepped doping of the CdTe layer with ZnTe buffer layer. Click here to View figure |

The results show that the structure C has the best efficiency. The open-circuit voltage, short-circuit current, fill factor and conversion efficiency for reference cell, simulated cell and proposed cell with optimized doping grading and BSF layer are given in Table 3.

|

Table3: Output Parameters of Different Cells. Click here to View table |

Conclusions

In this paper, we evaluated several step doping profiles in the absorber layer of CdS/CdTe cells. The conversion efficiency of 18.7% was obtained by optimization of the homo-junction location, doping concentrations and using ZnTe buffer layer that showed a noticeable improvement over the 16.3% efficiency of the reference cell with uniform doping profile of absorber layer. In addition, the modifications can be easily implemented during the fabrication process. The results show the conventional structure with ZnTe as a buffer back contact is the best structure. The open-circuit voltage, short-circuit current density, fill factor and total area conversion efficiency of the optimized solar cell structure are 952 mV, 25.97 mA/cm2, 78.5% and 18.7%, respectively under global AM 1.5 conditions.

References

- Amin, N.; Sopianb, K.; Konagai, M.; Solar Energy Materials and Solar Cells 2007, 91, 1202–1208

- Krishnakumar, L.; Han, J.; Klein, A.; Jaegermann, W.; Thin Solid Films 2011, 519, 7138-7141

- Meyers, P.V.; Albright, S.P.; Progress in Photovoltaics: Research and Applications 2000, 161-168

- Bonnet, D.; CdTe thin-film PV modules, In Practical Handbook of Photovoltaic: Fundamentals and Applications, Elsevier, Oxford, (2003)

- M.A. Green, K. Emery, Y. Hishikawa, W. Warta, E.D. Dunlop, Progress in Photovoltaics: Research and Applications 2011, 19, 84-92

- Kosyachenko, L.A.; Savchuk, A.I.; Grushko, E.V.; Thin Solid Films 2009, 517, 2386–2391

- Britt, J.; Ferekides, C.; Applied Physics Letters 1993, 62, 2851-2852

- Pena, J. L.; Ares, O.; Rejon, V.; Rios-Flores, A.; Camacho, J. M.; Romeo, N.; Bosio, A.; Thin Solid Films 2011, 520, 680-683

- Colegrove, E.; Banai, R.; Blissett, C.; Buurma, C.; Ellsworth, J.; Morley, M.; Barnes, S.; Gilmore, C.; Bergeson, J. D.; Dhere, R.; Scott, M.; Gessert, T.; Sivananthan, S.; Journal of Electronic Materials 2012, 41, 2833-2837

- Razykov, T.M.; Ferekides, C.S.; Morel, D.; Stefanakos, E.; Ullal, H.S.; Upadhyaya, H.M.; Solar Energy 2011, 85, 1580–1608

- Rios-Flores, A.; Ares, O.; Camacho, J. M.; Rejon, V.; Pena, J.L.; Solar Energy 2012, 86, 780–785

- Aramoto, T.; Ohyama, H.; Kumazawa, S.; Japanese Journal of Applied Physics 1997, 36, 6304-6305

- Wu, X.; Keane, J.C.; Dhere, R.G.; DeHart, C.; Albin, D.S.; Duda, A.; Gessert, T.A.; Asher, S.; Levi, D.H.; Sheldon, P.; in Proc. 17th Conf. IEEE European Photovoltaic Solar Energy, 2001, Munich, Germany, 995–1000.

- First Solar, Press Release: First Solar Sets World Record for CdTe Solar PV Efficiency, 2011, http://investor.firstsolar.com/releasedetail.com.

- First Solar Inc., 2013, http://www.firstsolar.com/en/Innovation/Advanced-Thin-Film-Modules.

- ATLAS User’s Manual, Silvaco International, 2010.

This work is licensed under a Creative Commons Attribution 4.0 International License.