Influence of Ferrous sulphate on growth and alpha-a Amylase production for Aspergillus fumigatus NTCC1222

Shalini Singh*, Sahibjot Kaur Cheema, Bineypreet Kaur, Navreet Kaur Mann

Lovely Professional University, Punjab, India-144402 shalinisingh.iit@gmail.com

DOI : http://dx.doi.org/10.13005/ojc/310273

Article Received on :

Article Accepted on :

Article Published : 30 May 2015

Stringent government regulations and increasing public awareness is forcing chemical industries to incorporate environment friendly products and processes. Biotechnological applications, in industries, thus, hold great future. Microorganisms and their metabolites/enzymes provide a number of eminent-economic as well as environment friendly solutions for such industries. Amylases are one of the most important industrial enzymes. Commercial production of amylases requires selection of the best of production conditions. This study evaluates the influence of varying concentration of Ferrous sulphate (Fe2+) on microbial growth and amylase production for Aspergillus, Aspergillus fumigatus NTCC1222. Ferrous sulphate enhanced growth (concentration of 100mg/L) by 1.83%, compared to the control. In contrast, it decreased amylase activity at all concentrations tested. As the concentration of ferrous sulphate increased, the amylase activity decreased. Amylases are metalloenzymes and the inhibition in amylase activity observed in the presence of ferrous ions may be due to competition between the exogenous cation and the protein associated cation, resulting in reduced metalloenzyme activity. Further studies will aim to evaluate the effect of different ferrous salts and different forms of iron on amylase production by Aspergillus fumigatus NTCC1222.

KEYWORDS:Environment; Amylase; Ferrous sulphate; Aspergillus fumigatus

Download this article as:| Copy the following to cite this article: Singh S, Cheema S. K, Kaur B, Mann N. K. Influence of Ferrous sulphate on growth and alpha-a Amylase production for Aspergillus fumigatus NTCC1222. Orient J Chem 2015;31(2). |

| Copy the following to cite this URL: Singh S, Cheema S. K, Kaur B, Mann N. K. Influence of Ferrous sulphate on growth and alpha-a Amylase production for Aspergillus fumigatus NTCC1222. Available from: http://www.orientjchem.org/?p=8920 |

Introduction

Amylase breaks down starch by hydrolysing the alpha bond such as α-1, 4 and α-1, 6 yielding glucose, maltose etc or a mixture of these small carbohydrates. It can be obtained from sources like plants, animals, bacteria, fungi etc (Pandey et al., 2000). Alpha-amylase is used in various industries like, in bread making, production of alcohol, production of chocolate syrup (Couto et al., 2006). Alpha amylase is also used as a textile desizing agent (Ahlawat et al., 2009), starch modification on coated paper in pulp and paper industry (Gupta et al., 2003), component in detergents to remove tough stains and makes the detergent environmentally safe, etc. (Mukherji et al., 2009).

The sources of α-amylase are plants, animals and micro-organisms; where microbial α-amylases are of great importance. The major advantage of using microorganisms for the amylase production is their economical bulk production capacity. Also microbes associated with microbial amylase production are also easy to manipulate to obtain enzymes of desired characteristics (Lonsane and Ramesh, 1990).

The Aspergillus species produce a large variety of extracellular enzymes. The fungus is capable of growth at 37 °C and can grow at temperatures up to 50 °C with conidia surviving at 70 °C conditions which it regularly encounters in self-heating compost heaps (Hernandez et al., 2006). Planchot (1995) observed that high amylase activity was shown by the amylase produced by Aspergillus fumigatus as compared to the amylase from the pig pancreas and Bacillus sp.

The present study evaluates the influence of ferrous sulphate on α-amylase production by indigenously isolated strain of Aspergillus fumigatus NTCC 1222 (Singh et al., 2014, 2013a,b, c, d, e).

Materials and Methods

Materials

All the chemical reagents and nutrient culture media were of analytical grade. Starch soluble, 3, 5-dinitrosalicylic acid (DNS) reagent were procured from Himedia Pvt. Ltd. India. All the other reagents and nutrient media were procured from LobaChemie Pvt. Ltd., India. Solid substrate (wheat bran) was procured from the local market of Jalandhar, Punjab, India.

Micro-Organism

The test fungal strain, Aspergillus fumigatus NTCC1222 was maintained by subculturing on potato dextrose agar (PDA) medium, incubated at 37°C for 3 days and subsequently stored at 4°C. For long term preservation, the test fungal strain was inoculated on 15% glycerol slants and subsequently stored at -20°C. The test fungal strain produced amylase under optimized conditions of SSF i.e. incubation period (6 days), pH (6), temperature (37°C), nitrogen source (beef extract), nutrient salt solution (NSS) added at a substrate to moistening agent in the ratio of 1:3 (Singh et al 2014).

Pre-treatment of Solid Substrate

Wheat bran was washed with water for 3-4 times and then squeezed to remove water. It was dried, ground and, sieved through fine mesh of pore size 0.5 mm to obtain powdered form of the substrate.

Effect of ferrous Sulphate on growth and Amylase production for the test fungus

The growth medium (wheat bran agar medium) containing 2% w/v wheat bran and 2% w/v agar agar, was supplemented with 40mg/L-140 mg/L of ferrous sulphate. The growth medium was autoclaved, inoculated and incubated for 6 days at 37oC. The growth was measured by measuring the diameter of the fungal colony. Simultaneously, control growth medium (without ferrous sulphate supplementation) was inoculated with the test fungal strain and the growth was compared with that for ferrous sulphate-supplemented growth medium.

For determining the effect of ferrous sulphate on amylase production, the basal fermentation medium (containing nutrient salt solution, NSS and wheat bran) was supplemented with variable concentration of ferrous sulphate. NSS contained 5 g/L of beef extract, 1 g/L of NaCl, 1 g/L of MgSO4.H2O and 5 g/L of KH2PO4. 5 g of solid substrate was taken into 250 ml Erlenmeyer flasks. To this, 15 mL of Nutrient salt solution, NSS was added so as to maintain a substrate to moistening agent ratio of 1:3 (Shalini et al., 2013). These flasks were autoclaved, cooled, inoculated with two 5 mm diameter discs of test fungal strain grown on PDA medium and incubated at 37°C. After an incubation of 6 days, 15 mL of distilled water was added to each Erlenmeyer flasks and the contents were crushed with a glass rod. The flasks were placed on rotary shaker for 10 minutes at 200 rpm. The slurry, so obtained, was squeezed through 3-4 layers of cheese cloth and the extract was then centrifuged at 5000 rpm for 15 minutes. The supernatant was treated as crude enzyme (Singh et al., 2009). The amylase activity was determined using DNS method (Miller et al., 1989).

Statistical Analysis

All experiments were carried out in triplicates. The results for enzyme activity were mean ‘±’ standard deviation (SD) of the values and those for microbial growth were reported as an average of the values.

Results and Discussion

Effect of ferrous sulphate on growth and amylase production for test fungus

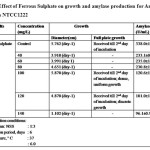

Ferrous sulphate was found to decrease amylase activity at all concentrations tested, as compared to the control (unsupplemented fermented medium). At a concentration of 120 mg/mL, ferrous sulphate drastically decreased the amylase activity by 71.5% while a drop of 31.71% in enzyme activity was observed for ferrous sulphate concentration of 80 mg/mL. Ferrous sulphate enhanced (1.83%) growth of the test fungus only at a concentration of 100 mg/mL as compared to unsupplemented growth medium. Thus, for ferrous sulphate, higher decrease in amylase activity was observed as the concentration of the metal salt increased. Similarly, a higher decrease in growth was observed for increasing concentration of the metal salt. In contrast, Alaria et al., (2013), Mishra et al., (2014), Suri Babu and Hemlata (2014) has reported an increase in amylase activity in the presence of ferrous sulphate for bacterial cultures tested. Zhang et al., (1983) reported that ferrous ions were essential for the amylase production though its absence hardly affected the growth of the culture. At the same time, Pandey et al. (2000), Lo et al., (2001) and Dey et al. (2003) has reported variable influence of Fe2+ ions on amylase activity. On the other hand, Sindhu et al., (2011) reported inhibitory action of ferrous ions on amylase activity produced by Penicillium janthinellum. Most amylases are metallo enzymes containing at least one metal atom per molecule of enzyme. This metal plays a role in catalytic activity. The inhibition observed in the presence of ferrous ions may be due to competition between the exogenous cation and the protein associated cation, resulting in reduced metalloenzyme activity (Sindhu et al., 2011). Nwagu and Okolo (2011) reported increase in amylase activity in the presence of Fe2+ for Aspergillus fumigatus.

|

Table1: Effect of Ferrous Sulphate on growth and amylase production for Aspergillus fumigatus NTCC1222 Click here to View table |

References

- Pandey, A.; Nigam, P.; Scoccol, C.R.; Soccol, V.T.; Singh, D.; Mohan, R. Appl. Biochem, 2000, 31:135- 152.

- `Couto, S.R. and Sanromán, M.A. Journal of Food Engineering, 2006, 76: 291-302.

- Ahlawat, S.; Dhiman, S.S.; Battan, B.; Mandhan, R.P.; Sharma, J. Process Biochemistry, 2005, 44: 521–526.

- Gupta, R.; Gigras, P.; Mohapatra, H.; Goswami V.K.; Chauhan B. Process Biochem., 2003, 38: 1599 – 1616.

- Mukherjee, A.K.; Borah, M.; Raí S.K. Biochem. Eng. J., 2009, 43:149–156.

- Lonsane, B. K. and Ramesh M.V. Adv. Appl. Microbiol., 1990, 35: 1-55.

- Herandez, M.S.; Rodríguez, M.R.; Guerra, N.P.; Roses R.P. J. Food Process Eng., 2006, 73: 93–100.

- Planchot, V.; Colonna, P.; Gallant, D.J.; Bouchet, B. Journal of Cereal Science, 1995, 21(2): 163–171.

- Singh, S.; Singh, S.; Sharma, L.; Bali, V.; Mangla, J. BioMed Research International, Volume 2014. Article ID 215748, 9 pages, http://dx.doi.org/10.1155/2014/215748, 2014.

- Singh, S.; Cheema, S.K.; Kaur, B.; Mann, N.K.. International Journal of Engineering Research and Technology, 2013a, 6 (8), 67-69.

- Singh, S.; Cheema, S.K.; B. Kaur, N. K. Mann, International Journal of Biotechnology and Bioengineering Research, 2013b, 4(6), 555-560.

- Singh, S.; Kaur, B.; Mann, N.K.; Cheema, S.K. International Journal of Biotechnology and Bioengineering Research, 2013c, 4(7), 697-702.

- Singh, S.; Mann, N.K.; Kaur, B.; Cheema, S.K. International Review of Applied Engineering Research, 2013d, 4(2), 117-122.

- Miller, G.L. Analytical chemistry, 1959, 31:426.

- Alariya, S.S.; Sethi, S.; Gupta, S.; Gupta, B.L. Scholars Research Library, Archives of Applied Science Research, 2013, 5 (1):1 5-24.

- Mishra, T.; Ahluwalia, S.; Joshi, M. Pelagia Research Library European Journal of Experimental Biology, 2014, 4(3):588-594.

- Suribabu, K.; Hemalatha, K.P.J. International Journal of Engineering Sciences & Research Technology, 2014, 926-934

- Zhang, Q.; Tsukagoshi, N.; Miyashiro, S.; Udaka, S. Applied and Environmental Microbiology, 1983, 46(1): 293-295.

- Lo, F-H.; Lin, L-L.; Chen, H-L.; Hsu, W-H.; Chang, C-T., 2001, 36, 743-750.

- Dey, G.; Bhupinder, S.; Banerjee, R. Braz. arch. biol. technol., 2003, 46, 167-176.

- Sindhu, R.; Suprabha, G.N.; Shashidhar, S.; Biotechnol. Bioinf. Bioeng., 2011, 1(1):25-32.

- Nwagu, T.N.; Okolo, B.N. Asian Journal of Biotechnology, 2011, 3(1): 46-57.

- Singh,S.; Dutt, D.; Tyagi, C.H.; Upadhyaya, J.S. New Biotechnology, 2009, 26: 3/4.

This work is licensed under a Creative Commons Attribution 4.0 International License.