Studies on Frying Quality of Virgin Coconut Oil and Shortening Blends

Muhammad Nor Omar, M H Nor-Hazwani, Muhd N. M. Nazreen, Ahmad Muzammil Zuberdi

Kulliyyah of Science, International Islamic University Malaysia, Indera Mahkota, 25200 Kuantan Pahang Malaysia

DOI : http://dx.doi.org/10.13005/ojc/300344

Article Received on :

Article Accepted on :

Article Published : 20 Sep 2014

The frying performances of palm solid shortening (PS) and virgin coconut oil (VCO) blends were evaluated. The fresh chickens were fried in a blended frying medium using an open fryer for 8 hours per day intermittently at 30 min interval for five consecutive days. Three types of oils were used; i.e. palm shortening without blending (PS), a blend of VCO: PS (10:90), and a blend of VCO: PS (20:80). The frying oils were collected periodically and their fatty acid composition (FAC), free fatty acid (FFA) content, total polar compound (TPC) and total polymer material (TPM) were determined. In addition, the fried chicken was subjected to the analyses of oil absorption and sensory evaluation. The results showed that the frying performance of the VCO:PS (20:80) blend was better than VCO:PS (10:90) blend and PS in terms of TPM and TPC contents. The VCO:PS (20:80) gave TPC and TPM values of 17.4 and 1.40% respectively, the blend of VCO:PS (10:90) gave values of TPC and TPM of 18. 7 and 2.20% respectively, whilst PS with TPC of and TPM of 20.5 and 3.02 % respectively. Meanwhile, the oil absorption patterns showed that the fried chicken in VCO: PS (10:90) blend absorbed less oil compared to chickens fried in PS and VCO:PS (20:80) blend. The oil uptake in chickens fried in VCO:PS (10:90) blend was 1.75%, while in PS and VCO:PS (20:80) blend were 2.82 and 2.57 % respectively. In term of sensory evaluation, the addition of virgin coconut oil (VCO) to palm based solid shortening (PS) showed significant differences (p < 0.05) on crispiness, taste and overall scores on the 1st , 3rd and 5th day of frying. Although there were no significant difference on oiliness on the 1st and 3rd day, there was a significant difference on the 5th day of frying. In conclusion, the addition of a small proportion of VCO in PS would improve the frying performance of oil as well as sensory scores of the fried products.

KEYWORDS:Frying performance; oil absorption; palm shortening (PS); virgin coconut oil (VCO)

Download this article as:| Copy the following to cite this article: Omar M. N, Hazwani M. H. N, Nazreen M. N. M. , Zuberdi A. M. Studies on Frying Quality of Virgin Coconut Oil and Shortening Blends. Orient J Chem 2014;30(3). |

| Copy the following to cite this URL: Omar M. N, Hazwani M. H. N, Nazreen M. N. M. , Zuberdi A. M. Studies on Frying Quality of Virgin Coconut Oil and Shortening Blends. Orient J Chem 2014;30(3). Available from: "http://www.orientjchem.org/?p=4864" |

INTRODUCTION

Fat contents in fried products become a great concern among consumers as taking an excess fat may contribute to overweight and obesity. As much 300 million people in the world population, as well as 64% of the United States adult population are considered either overweight or obese1,2,3 and this percentage has increased over the last four decades. It has been concluded that, a large number of medical dysfunctions have been associated with obesity/overweight including osteoarthritis, diabetes, cancer, cardiovascular and liver diseases4,5.

Nowadays, many fast food outlets are using vegetable frying medium to produce fried products, such as fried chicken, burgers and potato chips. All these products absorb oils between 6-15%. Potato chips will absorb oil up to 14 % when frying in palm olein6. A similar pattern on oil uptake is also observed when using different frying medium, including soybean oil, canola oil, olive oil and sunflower oil.

Many techniques and treatments are used in order to reduce oil uptake in fried products and improve the frying performance of the oil. One of the common techniques is by using a shortening and its blends. It has been found that, potato chips absorbed ca. 4.8 % when frying in palm solid shortening (PS)7, and further reduced to 4.3% when the shortening is blended with palm olein8. In terms of the total polar content (TPC) and the total polymeric material (TPM), the values obtained from palm solid shortening (PS) are lower than from palm olein (POo), and these values are further improved when using palm shortening-olein blends7, 8. In addition, PS also contains no trans fatty acids hence improves the human health7, 9.

The virgin coconut oil (VCO), which has been manufactured through fermentation and centrifugation technique has a lot of beneficial effects since it contains vitamin E and polyphenol10. The effects include lowering the lipid levels in serum and protecting low-density lipoprotein against oxidative stress11. In frying, the total oxidation value and polar compound in VCO is lower than in palm olein due to the presence of polyphenol compounds12.

The main objective of the present study is to evaluate the frying performance of palm solid shortening (PS) against VCO:PS blends using an open batch fryer. Besides that, assessment of the sensory qualities and oil uptake of fried products will also be carried out.

EXPERIMENTAL

Sample preparation

The fresh chickens were obtained from local market in December 2013. After chopping into small pieces, the chickens were washed and rinsed prior to frying. The palm shortening was obtained from local outlets while virgin coconut oil (VCO) was prepared in-house according to method previously reported13.

Frying experiments

The experiment was carried out using a One Well electric open fryer (IEF 171, one pot table top, Kualal Lumpur, Malaysia) according to the method previously reported7. The palm solid shortening (PS) and virgin coconut oil (VCO) blends were used to fry fresh chickens for 10 min at 180+ 2oC. An intermittent frying experiment was carried out for 8 hours per day over five consecutive days. Eight batches of chickens, with every batch weighing approximately 350 g, were fried daily with an interval of 60 minutes between batches. For the analysis of the physicochemical parameters, an oil sample of 100 ml was taken at the end of each day of frying. The samples were cooled, purged with nitrogen and kept at -18oC before analyses. The fried chicken samples were collected each day at the end of frying process and were kept at ambient temperature for sensory evaluation and oil uptake analysis.

Physicochemical Analysis of Fats

Oil uptake analysis

Total oil content of fried chickens was determined by Soxhlet extraction according to reported method7. The oil was extracted using a Soxtec™ 2050 Auto Fat Extraction System (Foss Analytical AB, Hoganas, Sweden). Two (2) gram of fried chicken sample was extracted for 2 h using n-hexane as a solvent.

Fatty Acid Composition Analysis by GC

The oil sample was methylated using a boron trifluoridemethanolic sodium hydroxide solution. The oil was analysed via on-column GC technique using Agilent 6890N gas chromatograph (Agilent, Avondale, USA) equipped with a flame ionization detector (FID). An HP-5 non-polar capillary column (50 m x 0.12 x 0.5 mm, SGE, Australia) was used and the temperature was initially kept at 50oC for 2 min and the programmed at 5oC per min to 250oC. The injector and detector temperature were 220o and 250oC respectively and He gas was used as carrier gas with a flow rate of 1.0 mL per min.

HPLC analysis of Total Polar Content and Total Polymeric Material

The total polar content (TPC) and the total polymeric material (TPM) were determined by HPLC technique according to methods previously reported7, 14, 15. HPLC analysis was carried out using a Waters HPLC system (Waters Associates, Milford, MA) equipped with a Rheodyn 7725 injector (10 ml sample loop), Waters 510 HPLC pump, 100oA Ultrastyle column and a refractive index detector.

Free Fatty Acid (FFA)

The free fatty acid (FFA) was determined as palmitic acid according to the MPOB Test Method16, which has been adopted from AOCS17.

Sensory Evaluation

For sensory evaluation, sufficient samples of freshly fried chickens were taken on the day 1, 3 and 5 of frying experiment and then served to trained panelists within 10 min after taken out of the fryer. Panelists were requested to evaluate the organoleptic attributes, i.e. colour, odour, oiliness, crispiness, taste and overall acceptance) of fried chickens. A nine-point hedonic scoring scale was used by the panel members to judge their perception, where 9 = extremely good and 1 = extremely bad. The sensory scores will be analyzed statistically using SPSS software (version 18.0 for Windows; SPSS Inc., Chicago, IL, USA).

RESULTS AND DISCUSSION

Oil uptake analysis

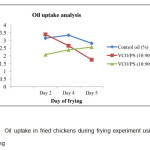

Figure 1 shows that the percentage of oil uptake/absorption by the chickens fried in three types of frying oils. By subtracting the initial oil content (0.12%) in the raw chicken, it was found that the oil uptake was the lowest in the chicken fried using VCO:PS (10:90) blend. During frying process, it was decreased from 3.39% to 1.75% whereas in PS, it was decreased from 3.15% to 2.82%. Meanwhile, the oil absorption of fried chickens in VCO: PS (20:80) was increased from 2.08 to 2.57%. The decreasing in oil uptake might be due to the presence of linolenic acid. As reported by Kita and Lisinska18, the fat absorption in fried products will be low when the amount of unsaturated fatty acid, i.e. linoleic acid in the frying medium is low. Analysis of fatty acid composition (FAC) showed that linoleic acid content of VCO: PS (10:90) blend (3.8%) was the lowest compared to its content VCO:PS (20:80) blend (3.9%) and PS (4.3%).

|

Figure1: Oil uptake in fried chickens during frying experiment using blended shortening |

Analysis of fatty acid composition (FAC)

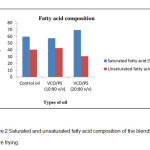

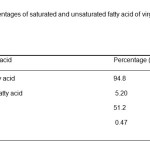

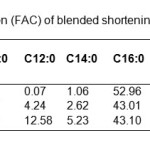

Table 1 shows the fatty acid composition of PS and VCO:PS blends. The VCO oil indicated that very high proportion of saturated fatty acid (94.8%) while the unsaturated fatty acid was only 5.2%. Apart from that, lauric acid in VCO constituted 51.2% while linoleic acid is 0.47%. When blending with PS, lauric acid content was the highest in VCO: PS (20:80) blend (12.58%) compared to 4.24% in VCO: PS (10:90) blend and 0.07% in PS (Table 2). Consequently, before frying, VCO: PS (20:80) blend contained the highest proportion of saturated fatty acids (69.3%) as compared to VCO: PS (10:90) (57.3%) and PS (59.6%) (Figure 2). After the 5th day of frying, VCO: PS (20:80) blend still contained a higher amount of saturated fatty acids (67.3%) than VCO: PS (10:90) blend (64.7%) and PS (62.3%).

|

Figure2: Saturated and unsaturated fatty acid composition of the blends before frying. Click here to View table |

|

Table1: Percentages of saturated and unsaturated fatty acid of virgin coconut oil Click here to View table |

In term of linoleic acid content, it was showed that VCO: PS (10:90) blend has the highest linoleic acid (2.82%) compared to VCO: PS (20:80) blend (5.13%) and PS (6.33%). On the 1st day of frying, linoleic acid decreased to 5.04% in PS and 3.92% in VCO: PS (20:80) blend while increased to 5.93% in VCO: PS (10:90) blend (Figure 3). After frying for 5 days, linoleic acid was decreased to 4.31% in PS and 3.81% in VCO: PS (20:80) blend while in VCO: PS (10:90) blend, it was increased to 3.82%. The lauric acid content was also changed significantly. On the 5th day of frying, VCO: PS (20:80) blend still consisted the highest content of lauric acid which the value of 8.9% compared to VCO: PS (10:90) blend (4.3%) and PS (0.13%) (Figure 4). Lauric acid is a medium chain fatty acid which found abundant in coconut oil and VCO that acts as antioxidant properties that may capable to increase the stability of oil during frying20. The addition of virgin coconut oil in vegetable oil believed to reduce the oil degradation during frying as reported by Ghazali et al12, virgin coconut oil capable to increase the stability of oil during frying because the mode of virgin coconut oil extraction retains more biologically active component such as vitamin E and polyphenol compared to coconut oil.

|

Table2: Fatty acid composition (FAC) of blended shortenings. Click here to View table |

|

Figure4:Fatty acid composition (FAC) in blended shortenings after the 5th day of frying. Click here to View table |

Free Fatty Acid Content

In this study, the free fatty acid (FFA) content was used as the principal indicator of frying oil quality in industry. It was found that the changes in FFA level of the three different oils during frying had increased with the increasing of frying time (Figure 5). The FFA value of PS increased gradually from 0.05% (before frying) to 1.19% after the 5th day of frying. When blending, the VCO: PS (10:90) blend, the FFA values were increased from 0.05% to 1.20% while in VCO: PS (20:80) blend, it increased from 0.05% to 1.15%. It was also found that, the VCO: PS (20:80) blend has the lowest FFA content whereas the highest percentage of FFA was in VCO: PS (10:90) blend (Figure 4). According to Innawong20, the increase in FFA value might be due to the hydrolysis process in the presence of water from food and high temperature of frying. The result of VCO: PS (20:80) blend was the lowest content of FFA due the higher saturated fatty acid (SFA) content as SFA will reduce the rate of hydrolysis during the frying. However, FFA values in all three different blends are still far below the maximum discard point of 2-2.5%21.

|

Figure5: Free fatty acid (FFA) values of blended shortening during frying Click here to View Figure |

Total Polymer Materials (TPM)

Based on the result obtained, the TPMs showed a different trend in PS and VCO:PS blends. After frying for five consecutive days, the polymer formation was higher in PS than VCO:PS blends (Figure 6). The TPM in VCO: PS (20:80) blend was the lowest (1.40%) compared to TPM values in VCO: PS (10:90) blend (2.20%) and in PS (3.02%). The polymer compounds are formed as a result of oxidative and thermal reaction22 which lead to the formation of volatile and non volatile decomposition product due to oil degradation. Paradis and Newar23 also confirmed that the higher content of saturated fatty acids are reliable indicators of oil quality. The VCO: PS (20:80) blend has the lowest TPM throughout frying due to the high in saturated fatty acids and low in unsaturated fatty acid contents. On the 5th day of frying, the percentage of saturated fatty acid in VCO: PS (20:80) was 67.3% compared to in VCO: PS (10:90) blend (64.7%) and in PS (62.3%). From this result, it can be concluded that both VCO:PS blends have lower TPMs than PS since these blends are able to resist the oxidation as they contain higher amount of saturated fatty acid and lauric acid compared to the control oil (PS). However, in the present study, all frying blends exhibited the TPM values were still far below the discard point of 10-16%21.

|

Figure6: The total polymer material (TPM) contents of blended shortenings during frying. Click here to View Figure |

Total Polar Compound (TPC)

The results of the TPC contents in three different blends during frying process were shown in (Figure 7). The percentage of the TPCs in all blends were changed against frying time. VCO: PS (20:80) blend tended to have the lowest value of TPC while PS has the greatest value. The TPC in VCO: PS (20:80) blend increased to 17.4% after the 5th day of frying. While in the VCO: PS (10:90) blend and PS, the TPC values were increased to 18.7% and 20.5% respectively. Nimitpornsuko24 reported that frying oil with high content of unsaturated fatty acid is more susceptible to oxidative degradation. Since total polar compounds (TPCs) are product of oil degradation, the high percentage of TPC in PS indicated that it was less stable during frying than VCO:PS blends. It was probably due to low content of saturated fatty acid compared to oil blends as reported earlier25. However, the TPC values in all blends were below the descard limit of 24%21, thus the used blends were still suitable for human consumption.

|

Figure7: The total polar (TPC) contents of blended shortenings during frying. Click here to View Figure |

Sensoray Evaluation

From the sensory mean scores on the Day 1, there were significant differences (p <0.05 ) in terms of colour, odour, crispiness, taste and overall scores in all samples (Figure 8). In Day 3, the samples indicated that there were no significant difference in colour, odour and oiliness, while there was a significant difference (p <0.05 ) in crispiness, taste and overall scores in all samples (Figure 9). On day 5, there were no significant difference in colour, odour and crispiness while there was a significant difference (p <0.05 ) in oiliness, taste and overall scores in all samples (Figure 10). Throughout this study, the addition of virgin coconut oil had affected the consumer perception on the fried chicken on oiliness, taste and overall score of fried chickens, although it did not contribute to the colour, odour and crispiness. The sensory data generally showed that fried chickens in virgin coconut oil were of significantly different (p <0.05 ) from fried chickens in palm based solid shortening.

|

Figure8: Mean sensory score of fried chickens in control oil (PS), VCO:PS (10:90) and VCO:PS (20:80) of Day 1 Shortening during frying. Click here to View Figure |

|

Figure9: Mean sensory score of fried chickens in control oil (PS), VCO:PS (10:90) and VCO:PS (20:80) of Day 3 Click here to View Figure |

|

Figure10: Mean sensory score of fried chickens in control oil (PS), VCO:PS (10:90) and VCO:PS (20:80) of Day 5 Click here to View Figure |

CONCLUSION

This study found that virgin coconut oil (VCO) can improve the frying performance of palm based solid shortening (PS) during deep frying. The physicochemical properties of VCO:PS blends were better than palm solid shortening (PS) alone. In term of oil uptake, the chickens fried in VCO:PS blends absorbed less oil than in palm shortening (PS). Moreover, in term of sensory evaluation, the addition of virgin coconut oil to palm based solid shortening showed significant differences on the oiliness, taste and overall acceptability of fried chicken after repeated frying. In overall, it can be concluded that the addition of a small proportion of VCO in palm based solid shortening gave a major improvement in frying stability of oil.

ACKNOWLEDGEMENT

Thanks to the International Islamic University Malaysia (IIUM) and the Dean, Kulliyyah of Science for his permission to carry out this research.

REFERENCES

- Flegal, K. M.; Carroll, M. D.; Ogden, C. L.; Johnson, C. L. (2002). JAMA 2002,288, 1723-1727 doi:10.1001/jama.288.14.1723. PMID 12365955. http://jama.ama-assn.org/cgi/content/full/288/14/1723.

- Hill, J. O.; Wyatt, H. Obesity Res.2002, 10, 124S-130S doi: 10.1038/oby.2002.205; http://dx.doi.org/10.1038/oby.2002.205

- Haslam, D; James, W. P. (2005). Obesity. The Lancet2005, 366, 1197-1209 doi:10.1016/S0140- 6736(05)67483-1; http://dx.doi.org/10.1016/S0140-6736(05)67483-1; PMID 16198769.

- Bray, G. A. J. Clin. Endocrinol. Metab.2004,89, 2583-2589 doi:10.1210/jc.2004-0535. http://dx.doi.org/10.1210/jc.2004-0535; PMID 15181027.

- Lew, E. A.; Garfinkel, L. (1979). Variations in mortality by weight among 750,000 men and women. J. Chron. Dis.1979,32, 563-576. http://www.ncbi.nlm.nih.gov/pubmed/468958?dopt=Abstract&holding=npg.

- Razali, I.; Badri, M.Palm Oil Dev. 2003,38, 12-15 http ://palmoilis.mpob.gov. my/publications/pod3 8-p11.pdf

- Omar, M. N.; Nor-Nazuha, M. N.; Nor-Dalilah, M. N.; Sahri, M. M. Pak.J.Biol. Sci. 2010,13, 298-302 doi: 10.3923/pjbs.2010.298.302; http://dx.doi.org/10.3923/pjbs.2010.298.302

- Farhani, M. R. Frying performance of virgin coconut oil and palm olein blends, FYP thesis, International Islamic University Malaysia, Kuantan, (2010)

- Sundram, K. Palm Oil Dev.2009,42, 24-26.

- Nour, A. H.; Mohammed, F. S.; Yunus, R. M.; Arman, A. Inter. J. Chem. Technol. 2009, 1, 59-64 doi: 10.3923/ijct.2009.59.64; http://dx.doi.org/10.3923/ijct.2009.59.64

- Nevin, K. G.; Rajamohan, T. Clin. Biochem.2004, 37, 830 835 doi:10.1016/j.clinbiochem.2004.04.010, http://dx.doi.org/10.1016/j.clinbiochem.2004.04.010

- Ghazali, H. M.; Tan, A.; Abdulkarim, S. M.; Dzulkifly, M. H. J. Fd Agric. Environ. 2009,7, 23-27 http://www.isfae.org/scientficjournal/2009/issue3/pdf/food/4.pdf

- Nor-Hazwani, M. H. Oil absorption and deep-frying performance using virgin coconut oil and palm based solid shortening, FYP Thesis, International Islamic University Malaysia, Kuantan, (2011)

- Dobarganes, C.M.; Velasco, J.; Dieffenbacher, A. Pure Applied Chem.2000,72, 1563-1575 doi:10.1351/pac200072081563; http://dx.doi.org/10.1351/pac200072081563http://195.37.231.82/publications/pac/pdf/2000/pdf/7208×1563.pdf

- Dobarganes, C.M.; Marquez-Ruiz, G. In Deep Frying: Chemistry, Nutrition and Practical Applications, AOCS Press, Champaign, (2007)

- MPOB Test Method. A compendium of tests on palm oil products, palm kernel products, fatty acids, food-related products and others. Malaysian Palm oil Board, Bangi, Malaysia, (2004)

- AOCS Official Method Ca 5a-40. Free fatty acid. American Oil Chemists’ Society, Urbana, IL., (1997)

- Kita, A.; Lisinska, G. (2005). J. Sci. Fd. Agric. 2005,85, 2600-2604 doi: 10.1002/jsfa.2319, http://dx.doi.org/10.1002/jsfa.2319

- Marina, A. M.; Che Man, Y. B.; Nazimah, S. A.H.; Amin, I. Int. J. Fd. Sci. Nutr. 2009,60, 114-123 PubMed: 19115123

- Innawong, B. Improving fried product and frying oil quality using nitrogen gas in a pressure frying system. PhD thesis, Virginia Polytechnic Institute and State University, Blacksburg, (2001)

- Ismail, R.; Minal, J.; Sudin, N. A. Palm Oil Dev.2003,38, 1-4. http://mpob.gov.my/en/component/content/article/181-publications- back-issues/798-palm-oil-developments-issn-0127-3329

- Paradis, A. J.; Nawar, W. W. J. Am. Oil Chem. Soc.1981,58, 635-638 doi: 10.1007/BF02672382; http://dx.doi.org/10.1007/BF02672382

- Tompkins C.; Perkins, E.G. J. Am. Oil Chem. Soc.2000, 77, 223-229 doi: 10.1007/s11746-000-0036-2; http://dx.doi.org/10.1007/s11746-000-0036- 2

- Nimitpornsuko, N. Changes in Physical and Chemical Qualities of Used Frying Oils for Banana Slices. Mohidol University Publisher, Bangkok, Thailand, (2008)

- Sulieman, A. E. M.; El-Makhzangy, A.; Ramadan, M. F. J. Fd. Lipids 2006,13, 259-276 doi:10.1111/j.1745-4522.2006.00050.x; http://dx.doi.org/10.1111/j.1745-4522.2006.00050.x

This work is licensed under a Creative Commons Attribution 4.0 International License.